Black tea automatic production line

An automated production line and technology for black tea, applied in the direction of tea treatment before extraction, can solve the problems of unstable production quality, low production efficiency and high production cost, and achieve the effects of high quality and stable production quality, improved quality and efficiency, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

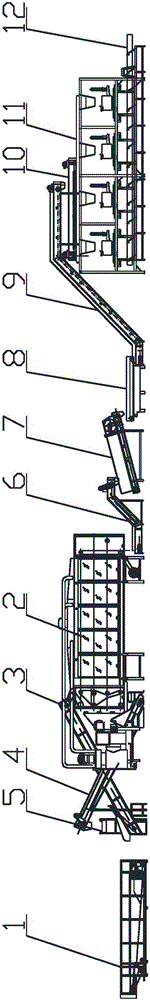

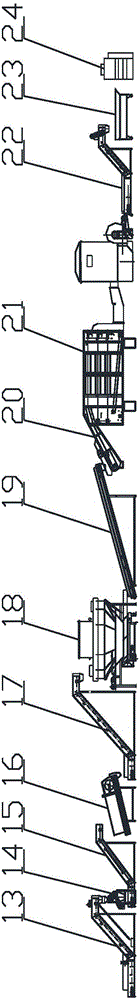

[0022] As shown in the figure, the present invention provides an automated black tea production line, including black tea withering machine 2, kneading unit 11, double drum deblocking machine 14, fermentation machine 18, chain plate dryer 21, flavoring machine 24, the aforementioned equipment Connect sequentially through the set of conveying and connecting equipment.

[0023] The black tea withering machine 2 contains four layers of stainless steel mesh belts, which increase the area of tea withering and improve the efficiency of withering. The stainless steel material is used to ensure the safety of production and avoid the inclusion of other impurities in the tea. The rolling and twisting unit 11 contains four parallel rolling and twisting machines, which can si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com