Glue pudding surface atomization structure

A technology of the same and horizontal plane, applied in the field of atomization structure on the surface of rice balls, can solve the problems of collision, dry cracking of rice balls, unfavorable production, etc., and achieve the effect of ensuring safe transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

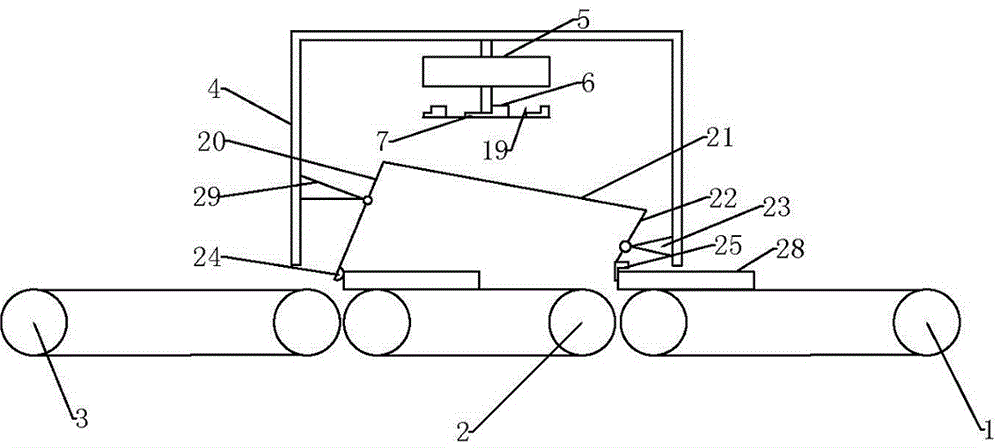

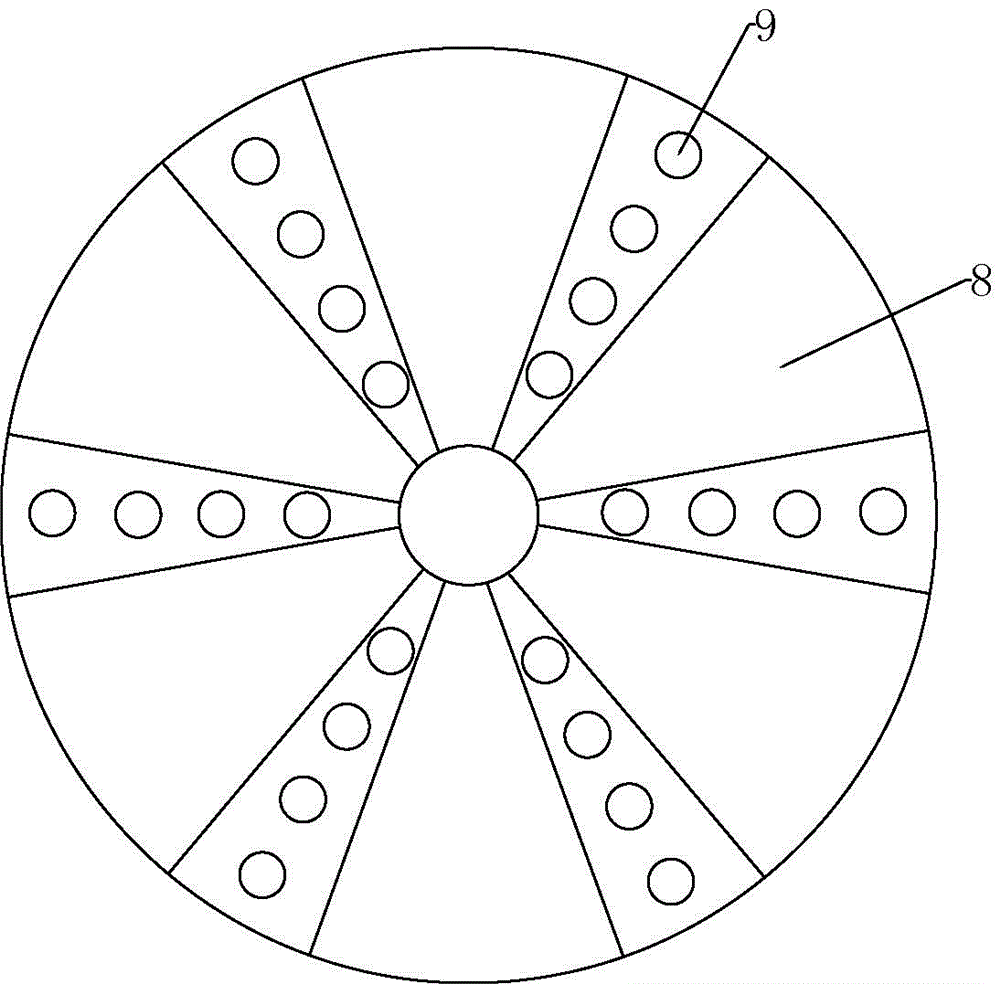

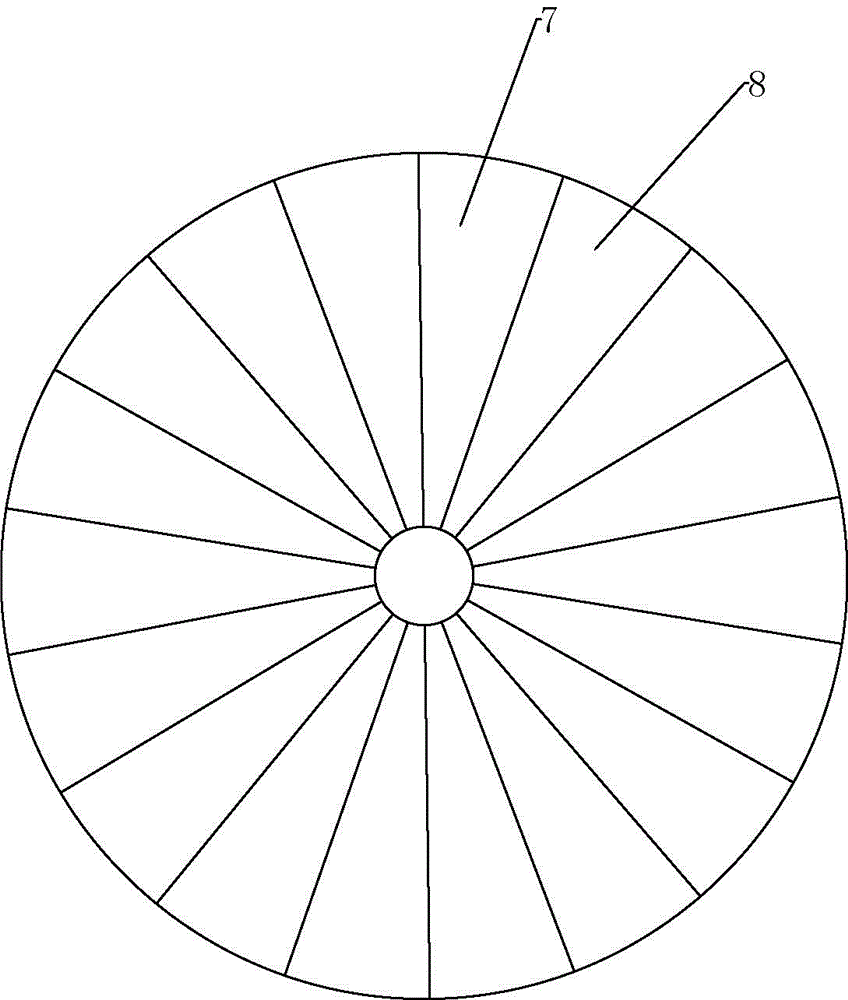

[0019] The reference signs in the drawings of the description include: the first conveyor belt 1, the second conveyor belt 2, the third conveyor belt 3, the water spray box 4, the water spray device 5, the protrusion 6, the baffle plate 7, the water spray chassis 8, and the spray head 9 , water inlet pipe 10, first helical guide channel 11, second helical guide channel 12, chute 13, first steel ball 14, elastic rod 15, second steel ball 16, metal block 17, regulating valve 18, protective device 19 , the third connecting rod 20, the second connecting rod 21, the first connecting rod 22, the first stabilizing block 23, the damping block 24, the pressing plate 25, the side pressing plate 26, the upper pressing plate 27, the glutinous rice ball disc 28, the second stabilizing block 29 .

[0020] Example basic reference figure 1 Shown: a surface atomization structure of glut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com