Construction engineering steel pipe transport tool

A technology of transportation tools and construction engineering, which is applied in transportation and packaging, vehicles used for freight, load fixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

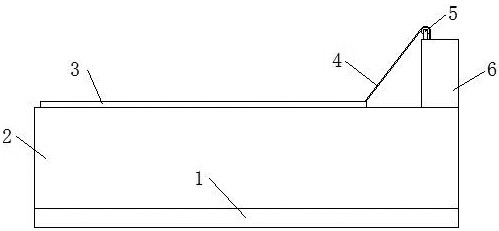

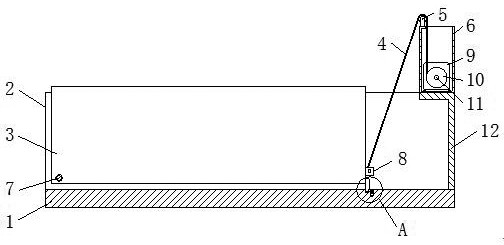

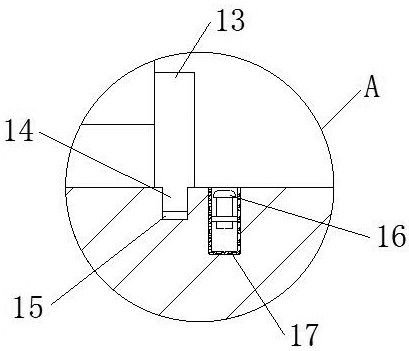

[0022] like Figure 1-5 As shown, the embodiment of the present invention provides a steel pipe transportation tool for construction engineering, including a carriage plate 1, which is characterized in that: the carriage plate 1, the two sides of the upper surface of the carriage plate 1 are fixedly connected with two symmetrically arranged protective and anti-collision side plates 2. Between the two anti-collision side panels 2, there is a steel pipe transportation box 3 on any side, and a top power protection box is installed on the side between the two anti-collision side panels 2, which is far away from the steel pipe transportation box 3. 6. An "L"-shaped fixed support plate 12 is fixedly connected between the two protective anti-collision side plates 2 on the side away from the steel pipe transport box 3, and the lower surface of the top power protection box 6 is fixedly connected with the upper surface of the fixed support plate 12. Limiting chute 18 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com