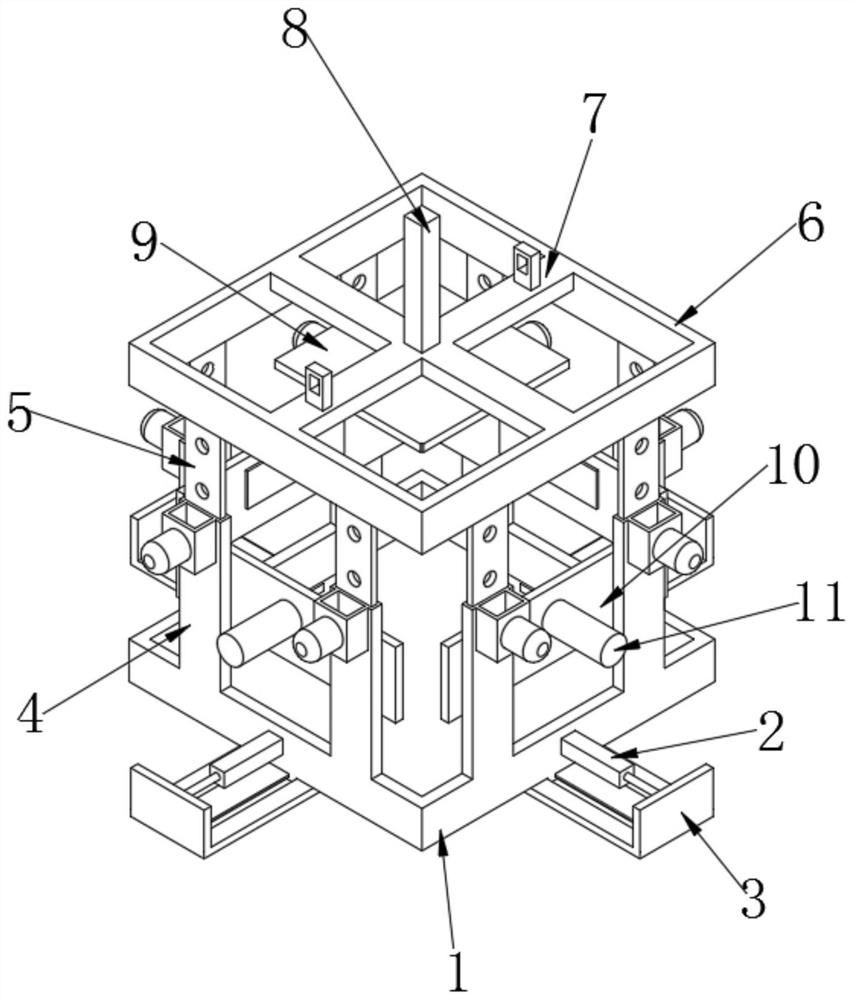

Transfer device for main transformer iron core stacking

A transfer device and iron core technology, applied in safety devices, inductor/transformer/magnet manufacturing, transportation and packaging, etc., can solve problems such as core and transfer device damage, iron core and transfer device collision, increase transportation costs, etc., to avoid collisions , Ensure safe transportation and reduce transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

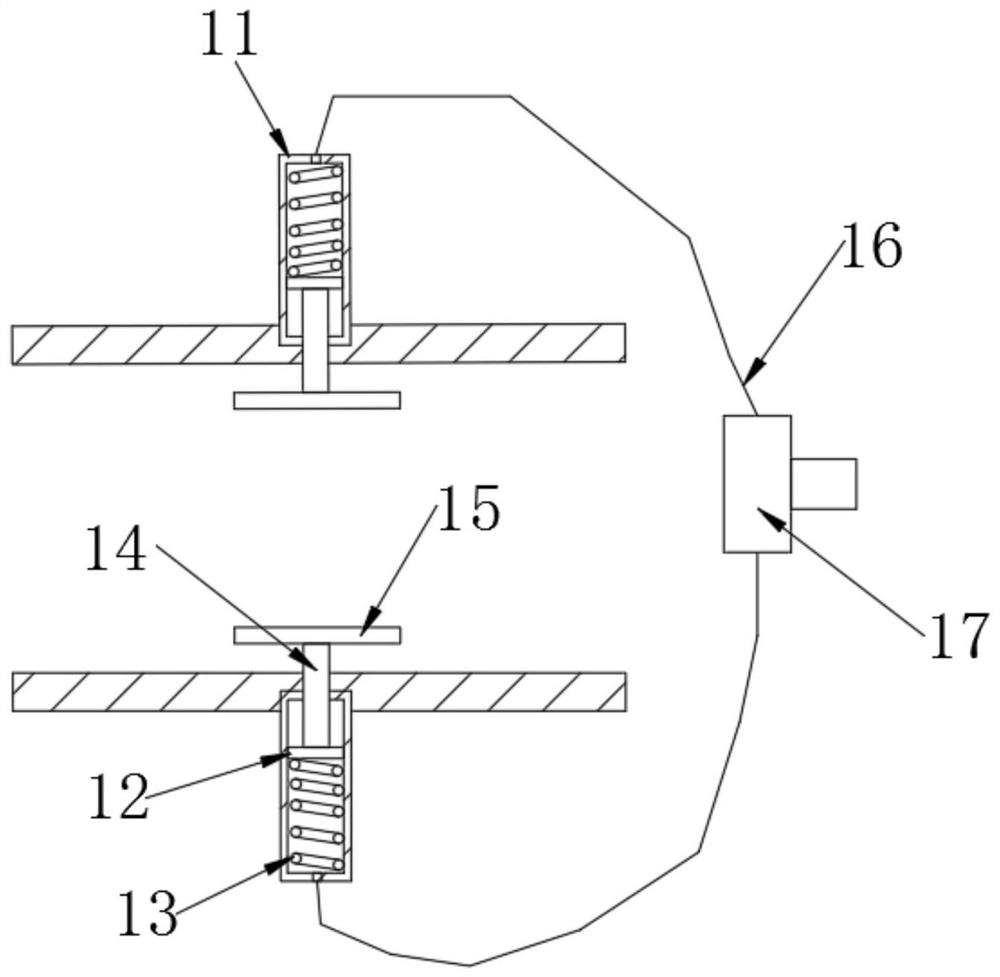

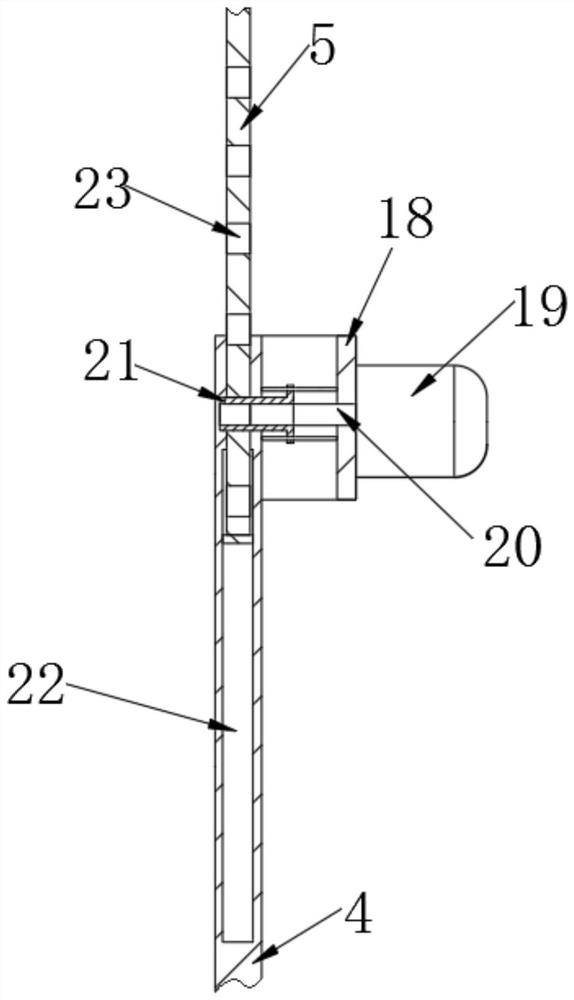

[0037] As an embodiment of the present invention, a limit block is installed on the outside of the insertion rod 21, a guide rod is installed on the inside of the motor base 18 and the outside of the fixed arm 4, and the guide rod passes through the limit block, and the insertion rod 21 and the threaded rod 20 are screwed together. And the insertion rod 21 is adapted to the socket 23, and when the threaded rod 20 rotates to drive the insertion rod 21 to expand and contract, the guide rod and the stop block cooperate to play a guiding role.

[0038] As an embodiment of the present invention, hanging lugs are arranged symmetrically on the top side of the cross support frame 7 to facilitate cooperation with a hoist.

[0039] As an embodiment of the present invention, the specific operation steps of the transfer device are as follows:

[0040]Step 1: Place the main transformer core on the base, and the top side of the base is provided with a limit slot matching the L-shaped baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com