Shaft temperature sensor used for rolling stock and manufacturing method thereof

A manufacturing method and technology of temperature sensor, which are applied to thermometers, instruments, thermometers and other directions using electrical/magnetic components directly sensitive to heat, can solve problems such as disadvantageous vehicle management personnel, critical driving safety, mastery, etc., to ensure vehicle operation. The effect of safety, prolonging service life and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

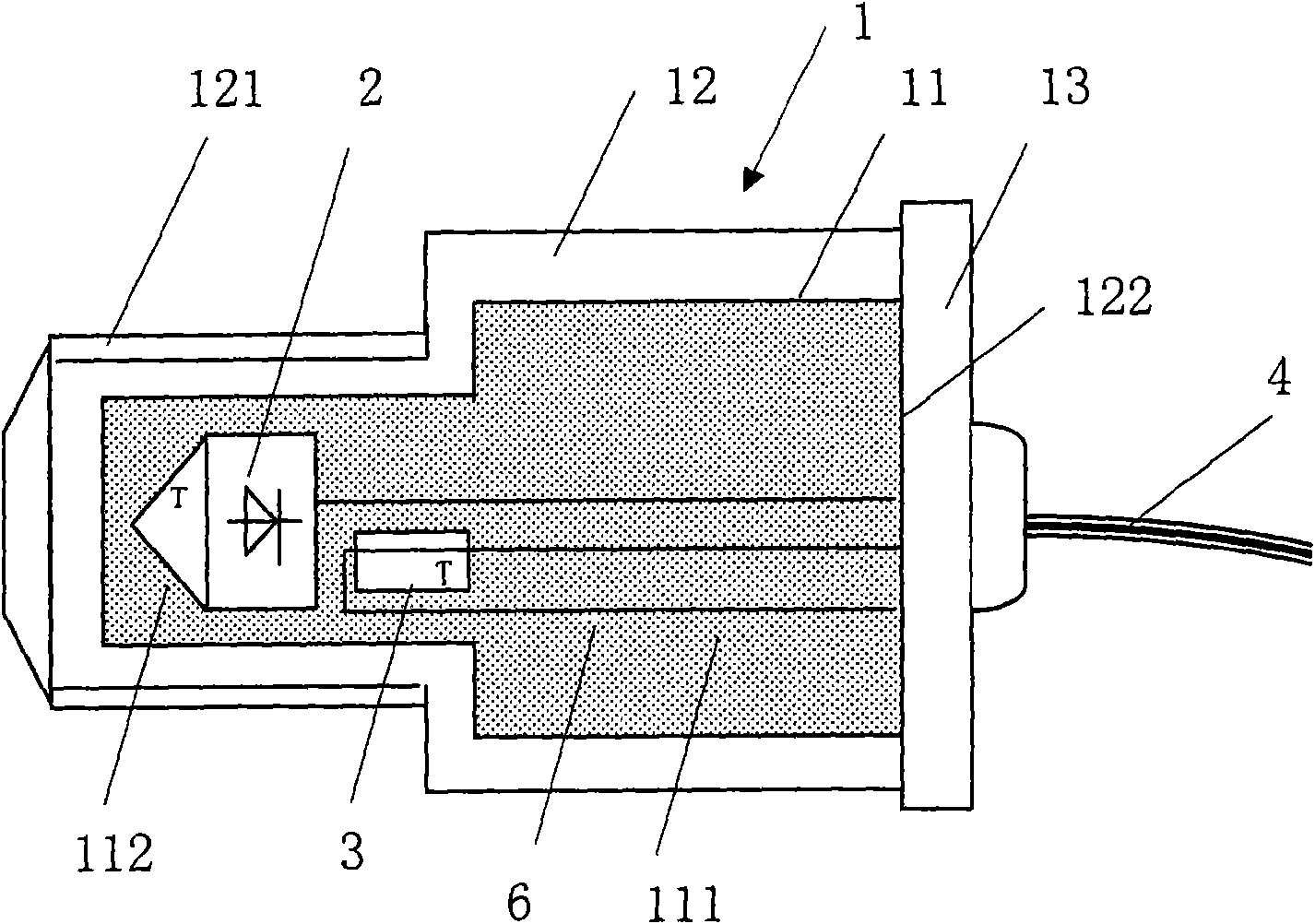

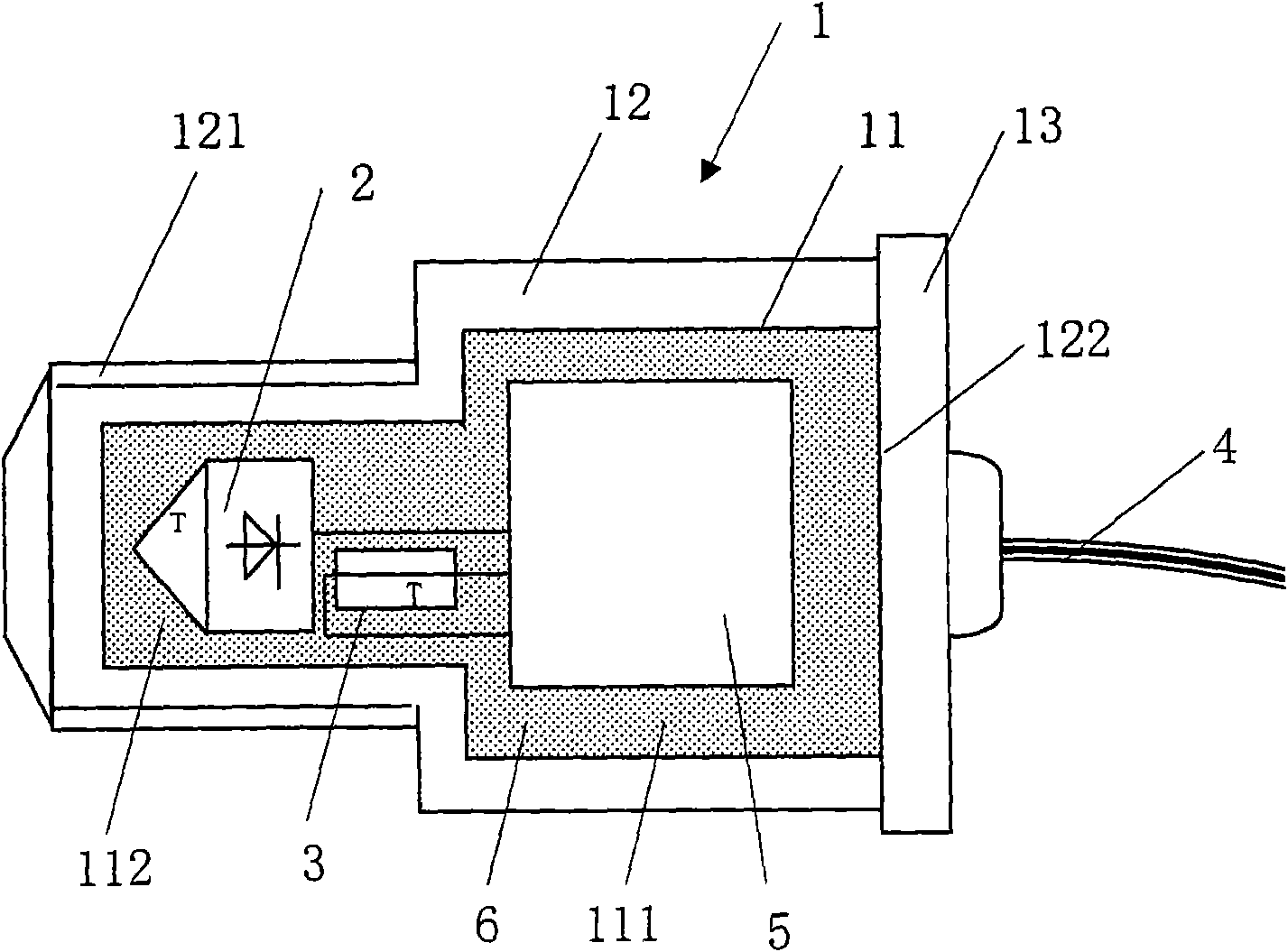

[0027] Such as figure 1 As shown, the present invention provides an axle temperature sensor for rolling stock, including a sensor housing 1. A temperature sensor 2 and a temperature fuse 3 are arranged in the sensor housing 1. The temperature sensor 2 displays the operating shaft of the locomotive When the temperature changes, the temperature fuse 3 is blown when the axle temperature is too high to ensure reliable failure alarms and safe locomotive operation.

[0028] In the present invention, the temperature sensor 2 can be a digital temperature sensor (such as the DS18B20 temperature sensor produced by Dallas Company), an analog temperature sensor, a semiconductor temperature sensor, a thermocouple temperature sensor, a thermistor temperature sensor, etc., a temperature fuse 3 Various types in the prior art can be used, such as the SM146A0 temperature fuse produced by NEC Japan Electric Company. Obviously, the melting temperature of the temperature fuse 3 is much lower than the ...

Embodiment approach 2

[0035] Such as Figure 3~10 As shown, another aspect of the present invention also provides a manufacturing method for manufacturing axle temperature sensors for rolling stock, including the following steps:

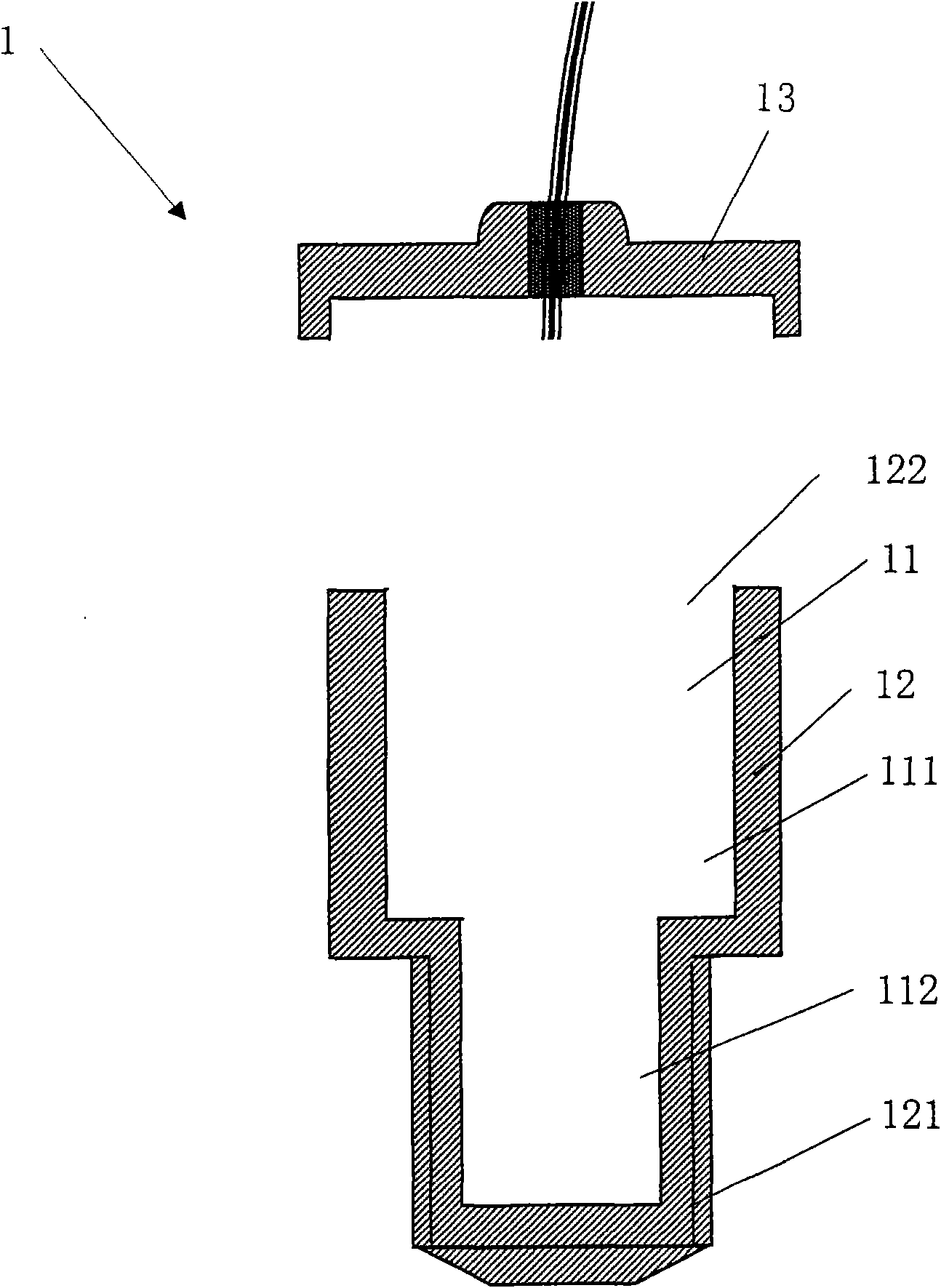

[0036] a) such as image 3 As shown, the sensor housing 1 is manufactured. The sensor housing 1 includes a main housing 12 with a cavity 11 and a cover 13. A main housing 12 may be in the shape of a stepped non-equal diameter including a large diameter section and a small diameter section. Cylinder, the corresponding chamber 11 includes a main body chamber 111 and a head chamber 112, the main housing 12 is provided with a thread 121 at the front and an opening 122 at the rear;

[0037] b) Place the shock-absorbing heat-conducting material 6, the temperature sensor 2 and the temperature fuse 3 in the chamber 11 of the main housing 12, so that the temperature sensor 2 and the temperature fuse 3 (and the circuit board 5) are embedded in the shock-absorbing heat conduction The in...

Embodiment approach 3

[0048] The principles and effects of this embodiment are the same as those of the second embodiment, and will not be repeated. The difference is that step b is different. Step b specifically includes: pouring a shock-absorbing thermal conductive material into the chamber of the sensor housing, and inserting the temperature sensor and temperature fuse into the shock-absorbing thermal conductive material before the shock-absorbing thermal conductive material is solidified , And ensure that it does not contact the inner wall surface of the sensor housing. In this embodiment, the temperature sensor 2, the temperature fuse 3 (and the circuit board 5) can also be embedded in the shock-absorbing heat-conducting material 6 to achieve shock-absorbing effect, and the drawings are no longer provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com