Producing and processing equipment of strange-taste lima beans and operation method thereof

A technology for processing equipment and peculiar-flavored beans, applied in the field of food processing and production equipment, can solve the problems of complicated operation, high cost, unsuitable for fried food processing, etc., and achieves convenient operation, guaranteed service life, and simple and compact structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

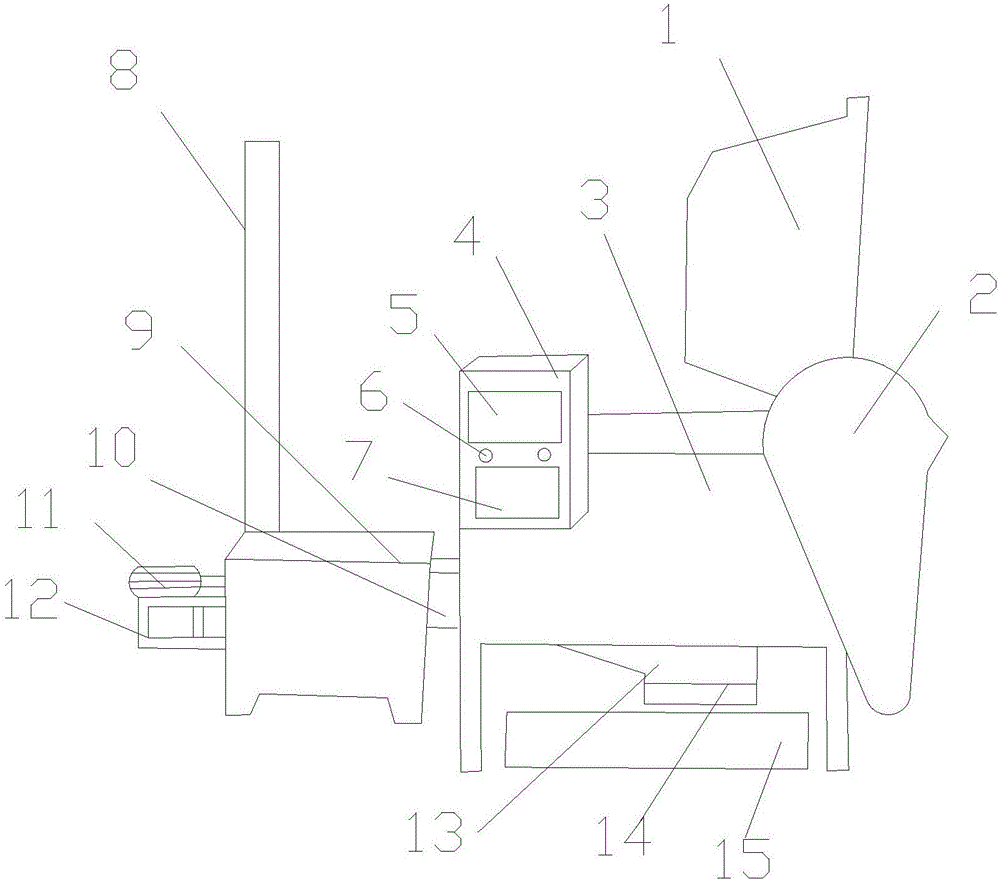

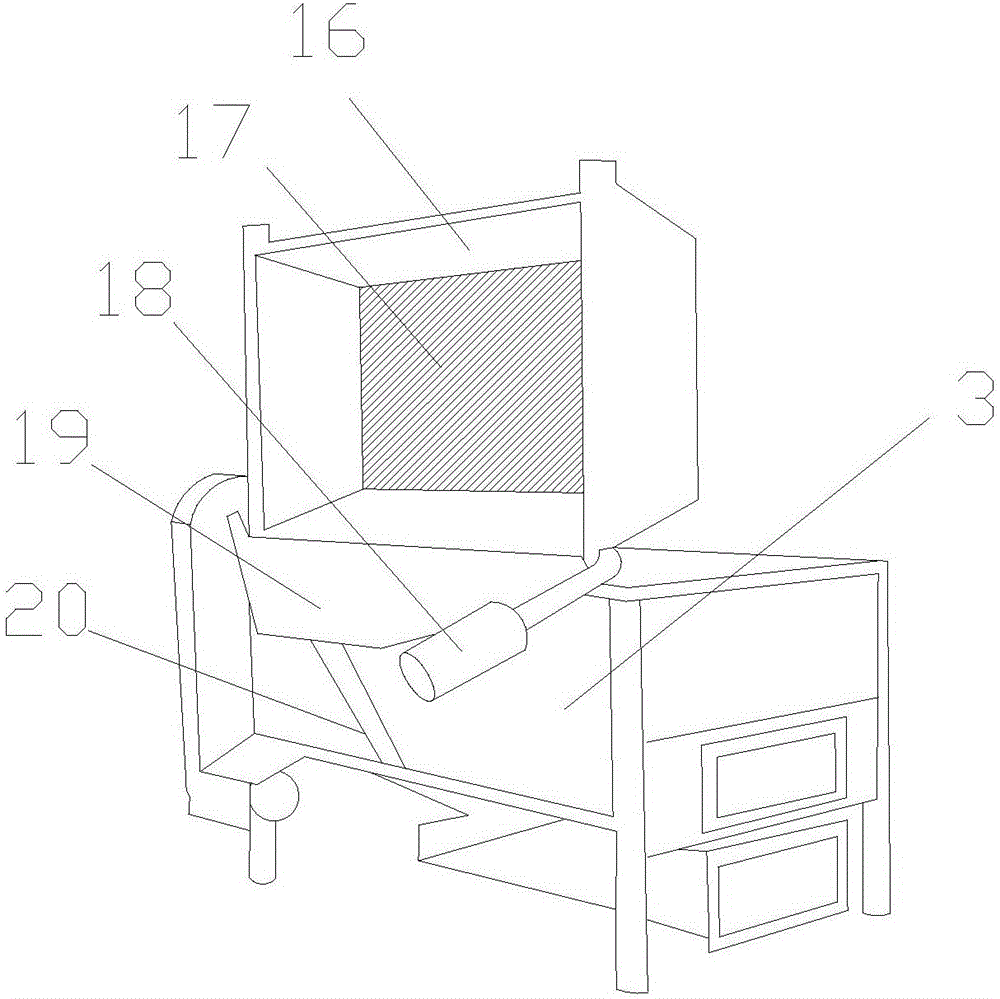

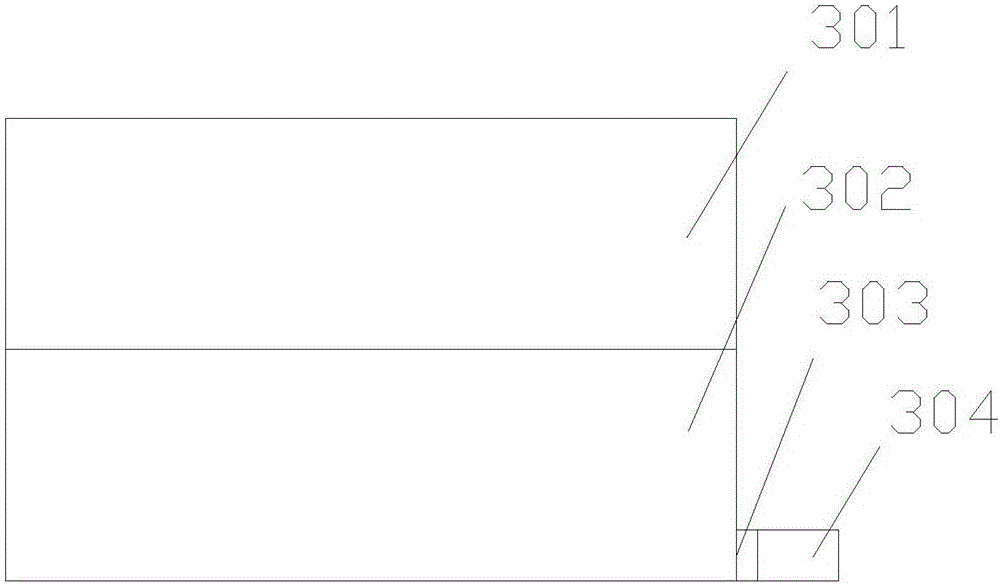

[0022] see figure 1 , figure 2 and image 3 , the present invention provides a kind of production and processing equipment of strange-flavored soybeans: its structure includes a hopper 1, a hopper control panel 2, a frying processing chamber 3, a controller 4, a display panel 5, an indicator light 6, an operation panel 7, a smoke Discharge pipe 8, furnace body 9, connecting pipe 10, motor 11, motor support seat 12, slag outlet 13, filter 14, residue collector 15, stainless steel basket 16, filter screen 17, adjustment rod 18, discharge port 19. Support rod 20, the hopper 1 is movably connected with the frying processing chamber 3 through the hopper control board 2, and the frying processing chamber 3 is movably connected with the furnace body 9 through the connecting pipe 10, and the furnace body 9 is provided with There is a flue gas discharge pipe 8, the furnace body 9 is movably connected with the motor 11, the motor 11 is fixed on the motor support base 12, the discharg...

Embodiment 2

[0025] see Figure 1-Figure 3 , the present invention provides a kind of production and processing equipment of strange-flavored soybeans: its structure includes a hopper 1, a hopper control panel 2, a frying processing chamber 3, a controller 4, a display panel 5, an indicator light 6, an operation panel 7, a smoke Discharge pipe 8, furnace body 9, connecting pipe 10, motor 11, motor support seat 12, slag outlet 13, filter 14, residue collector 15, stainless steel basket 16, filter screen 17, adjustment rod 18, discharge port 19. Support rod 20, the discharge hopper 1 is flexibly connected with the frying processing chamber 3 through the hopper control board 2, and the frying processing chamber 3 is provided with a controller 4, a display panel 5, an indicator light 6, and an operation panel 7 , the controller 4 is fixedly connected to the operation panel 7 through the display panel 5, the indicator light 6 is connected to the operation panel 7, the frying chamber 3 is movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com