Production facility for honey extraction and concentration

A technology for production equipment and honey, applied in the direction of filtration and separation, fixed filter elements, chemical instruments and methods, etc., can solve the problems of no honey, a large number of bacteria and impurities left by honey, etc., to facilitate maintenance, simplify production equipment, Guarantee the effect of safety and sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

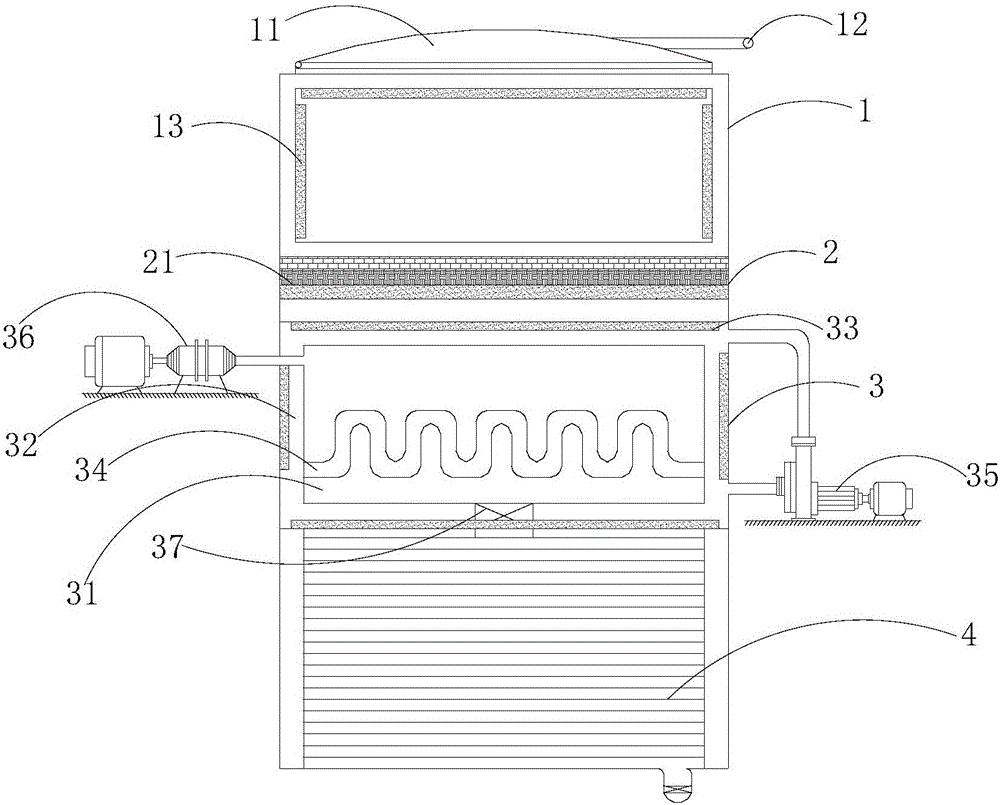

[0021] Such as figure 1 As shown, a production equipment for honey extraction, processing and concentration includes a honey melting tank 1, a filter device 2, a concentration warmer 3 and a tube cooler 4, and a sealing cover 11 is installed on the top of the honey melting tank 1, and A handle 12 is installed on the sealing cover 11, an electric heater 13 is installed on the inner wall of the honey-melting tank 1, and a filter device 2 is installed on the inner bottom surface of the honey-melting tank 1, and the filter device 2 is divided into a filter screen 21. The net 21 is provided with three layers, and the thickness increases sequentially from top to bottom. A concentration warmer 3 is installed below the filter screen 21, and the filter screen 2 is connected and communicated with the concentration warmer 3. The concentration warmer 3 is provided with an inner cavity 31 and a waterway 32, the waterway 32 is equipped with an electric heating device 33, the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com