Desalination system

A gas-water separator and inertial technology, applied in the field of desalination system, to achieve high-efficiency solid particle absorption, improve nozzle and air flow distribution, and realize the effect of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

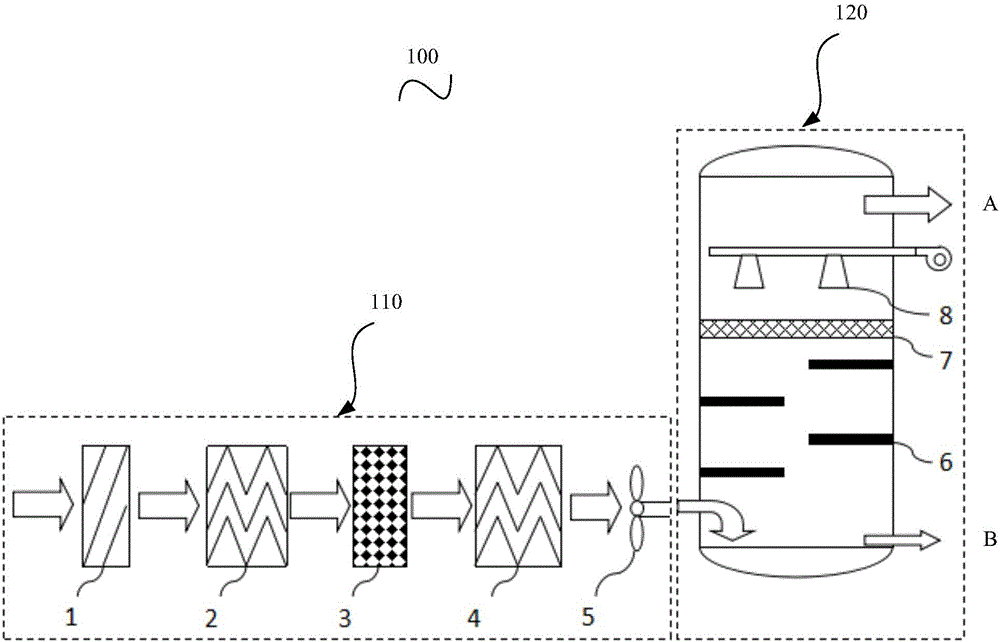

[0022] see figure 1 , Embodiment 1 of the present invention provides a desalination system 100 , including a first desalination module 110 and a second desalination module 120 . in:

[0023] The first desalination module 110 includes a filter 1, a three-stage filter 111 and a fan 5

[0024] Wherein, the three-stage filter 111 includes a front inertia stage air-water separator 2 , a wire mesh coalescer 3 , and a rear inertia stage air-water separator 4 .

[0025] Preferably, the filter 1 , the front inertial stage gas-water separator 2 , the wire mesh coalescer 3 and the rear inertial stage gas-water separator 4 are sequentially arranged along the horizontal direction.

[0026] It can be understood that the first desalination module 100 includes a front inertial stage gas-water separator 2, a screen coalescer 3 and a rear inertial stage gas-water separator 4. The inertial stage and the wire mesh stage are combined into a three-stage filter that can be removed. Large diameter...

Embodiment 2

[0035] Different from Embodiment 1, Embodiment 2 of the present invention provides a desalination system. The first desalination module includes two tertiary filters, which are arranged in series. The other structures are the same, and will not be repeated here. repeat.

[0036] It can be understood that in Example 2 of the present application, two third-stage filters connected in series can remove large-diameter particles in the sea breeze, and the removal efficiency is better.

[0037] It can be understood that in practice, multi-stage and three-stage filters can also be designed according to needs to meet different application requirements.

[0038] The desalination system provided by this application includes a first desalination module and a second desalination module. The first desalination module is composed of an inertial stage and a wire mesh stage to form a three-stage filter that can remove large-diameter particles in the sea breeze. The second desalination module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com