Intake arrangement for combustion chamber

A technology of air intake device and combustion chamber, which is applied in combustion engine, combustion air/combustion-air treatment, charging system, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

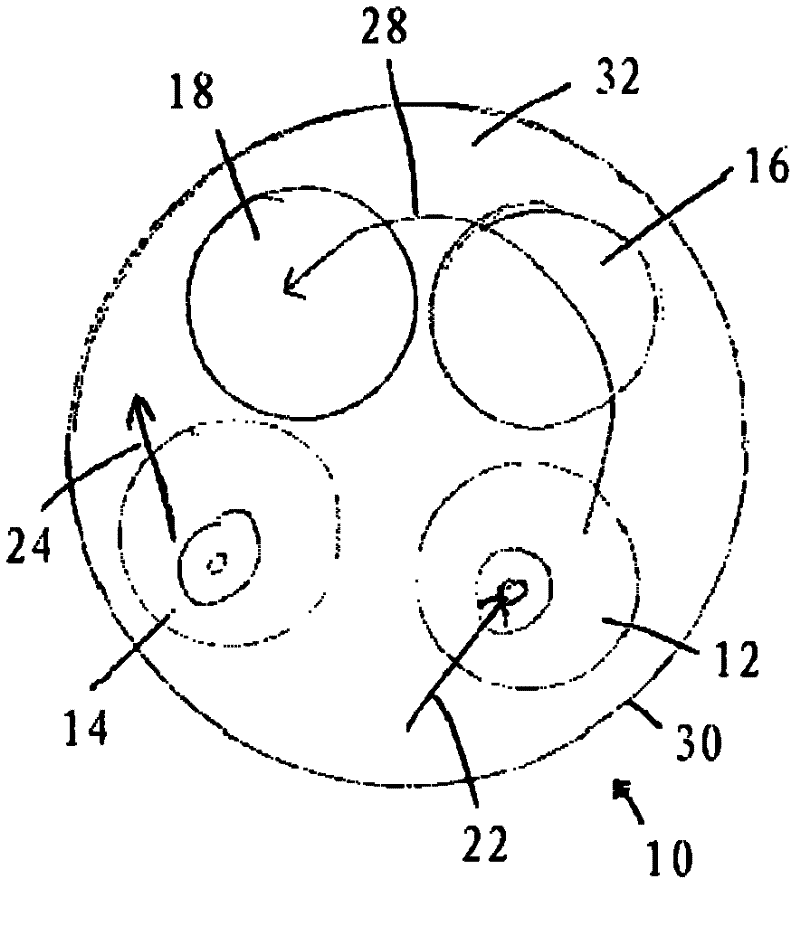

[0063] With reference to the accompanying drawings,figure 1 and 2 A conventional combustion chamber or cylinder 10 of an internal combustion engine, in particular a direct injection diesel engine, is shown. In its top wall 32 , the combustion chamber includes intake ports or ducts 12 , 14 to admit air, and exhaust ports 16 , 18 . As generally indicated by arrows 22, the first air intake 12 produces a flow substantially tangential to the wall 30 of the combustion chamber to create a high degree of swirl. As generally indicated by arrow 24 , the second intake port 14 produces a flow that is directed primarily axially into the combustion chamber. However, said flow includes a non-negligible rotational or tangential component, which produces a swirling swirl in the opposite direction to the rotation of arrow 22 , which leads to an overall reduction in the value of the swirl of the combustion chamber as indicated by arrow 28 .

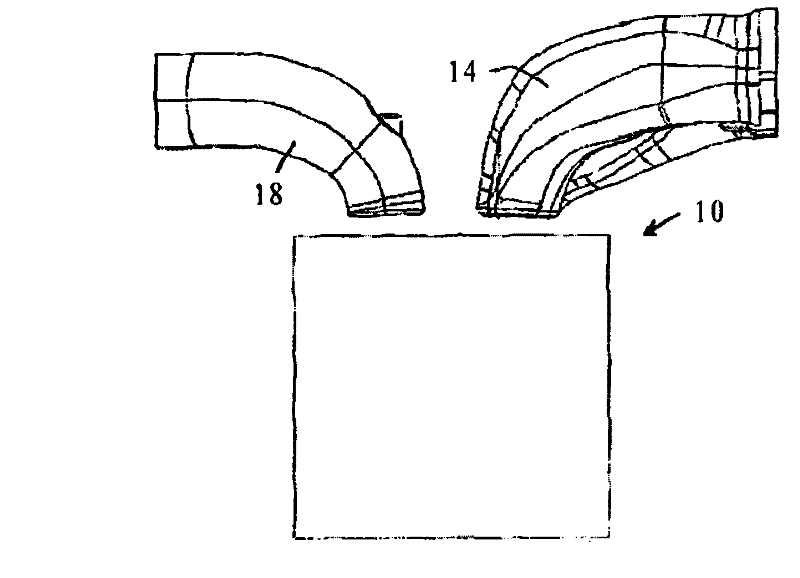

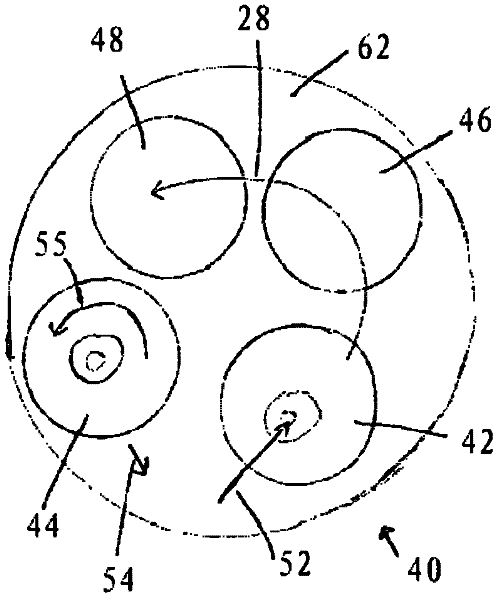

[0064] image 3 , 4 and 5 show a combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com