Thin wall header with a variable cross-section for solar absorption panels

A solar energy absorption panel and solar energy absorption technology, applied in the direction of solar thermal collectors, solar thermal collectors using working fluid, solar thermal collectors in specific environments, etc., can solve problems such as non-optimization, and achieve optimized thickness and temperature gradient. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

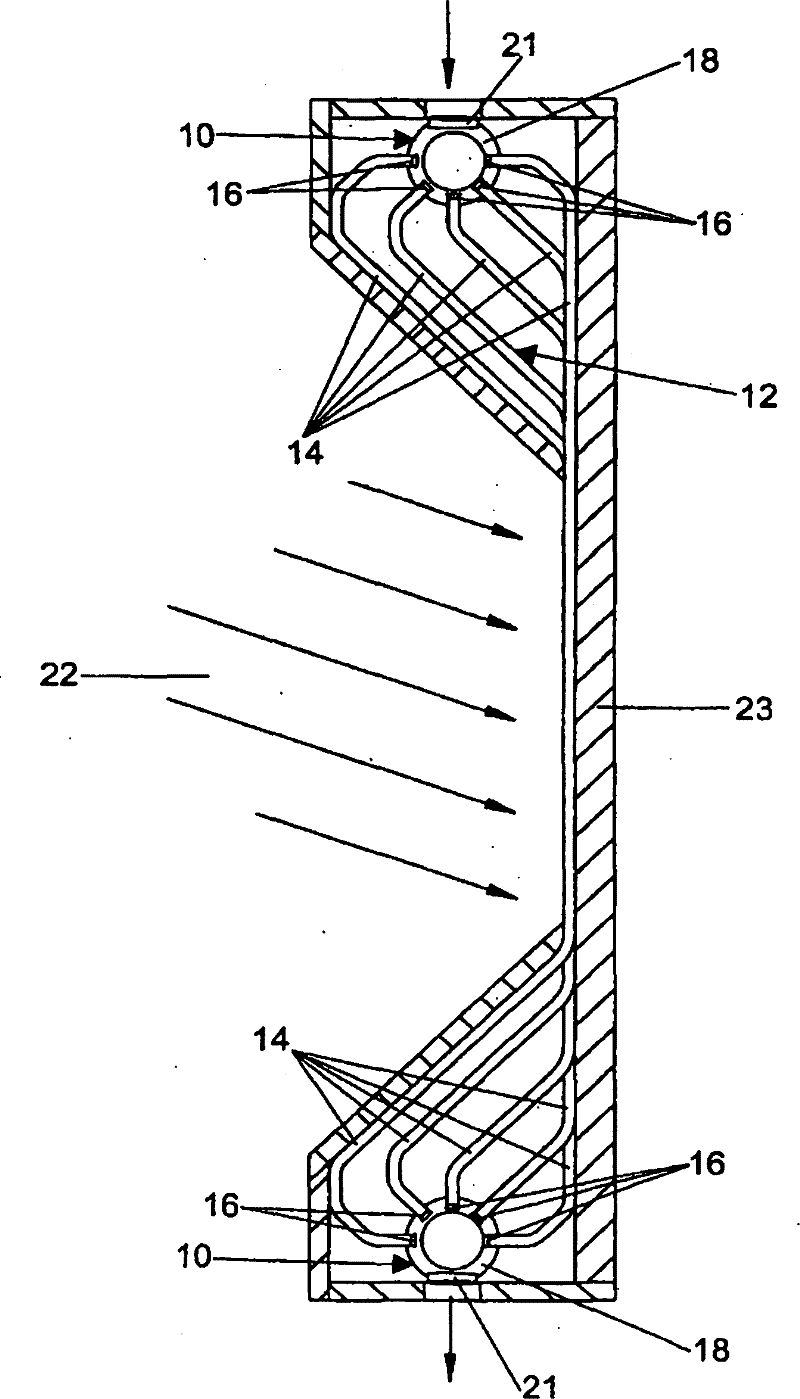

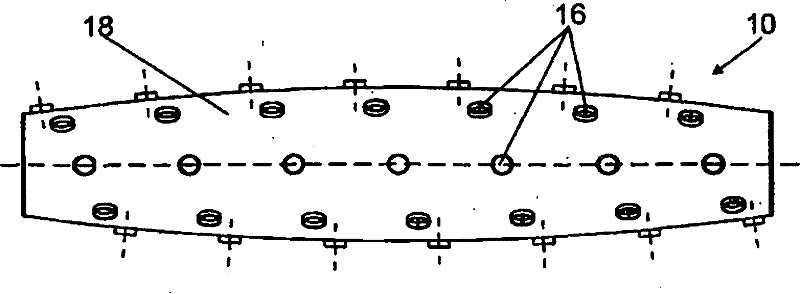

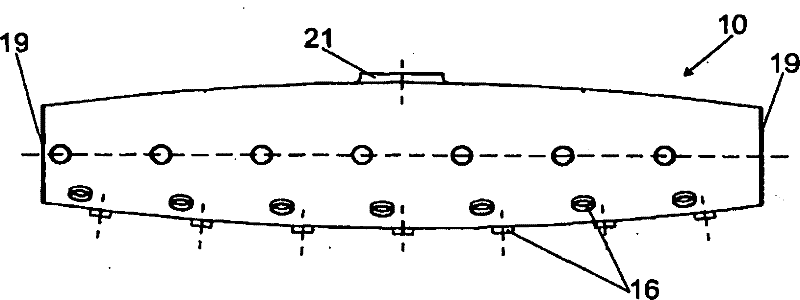

[0035] figure 1 A side view of the assembly of the current collector 10 of the preferred physical embodiment of the invention, arranged inside a solar absorbing panel 12, is shown. The solar absorber panel 12 is formed by a series of solar absorber tubes 14 parallel to each other and joined by means of joining nozzles 16 for joining the body 18 of the collector 10 .

[0036] The assembly of the collector 10 is formed by a body 18 of variable cross-section and closed side covers 19, which in Figures 2 to 6 shown in . The tube 14 is preferably butt-welded on the joining nozzle 16 .

[0037] Molten salt or the transfer fluid used enters and exits the solar absorber panel through inlet and outlet nozzles 21 joined to the collector 10 . The molten salt or transfer fluid absorbs thermal energy from solar radiation 22 reflected onto tube 14 by a field of heliostats (not shown).

[0038] The collector assembly is used to distribute heated salt or fluid to, or collect salt or flui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com