Automatic feeding system for water-based paint, and method for automatically feeding reaction kettle

A technology of automatic feeding and water-based paint, applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., can solve the problems of measuring tank or pipeline residue, slow feeding speed, etc., to improve production efficiency and improve The effect of cutting speed and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

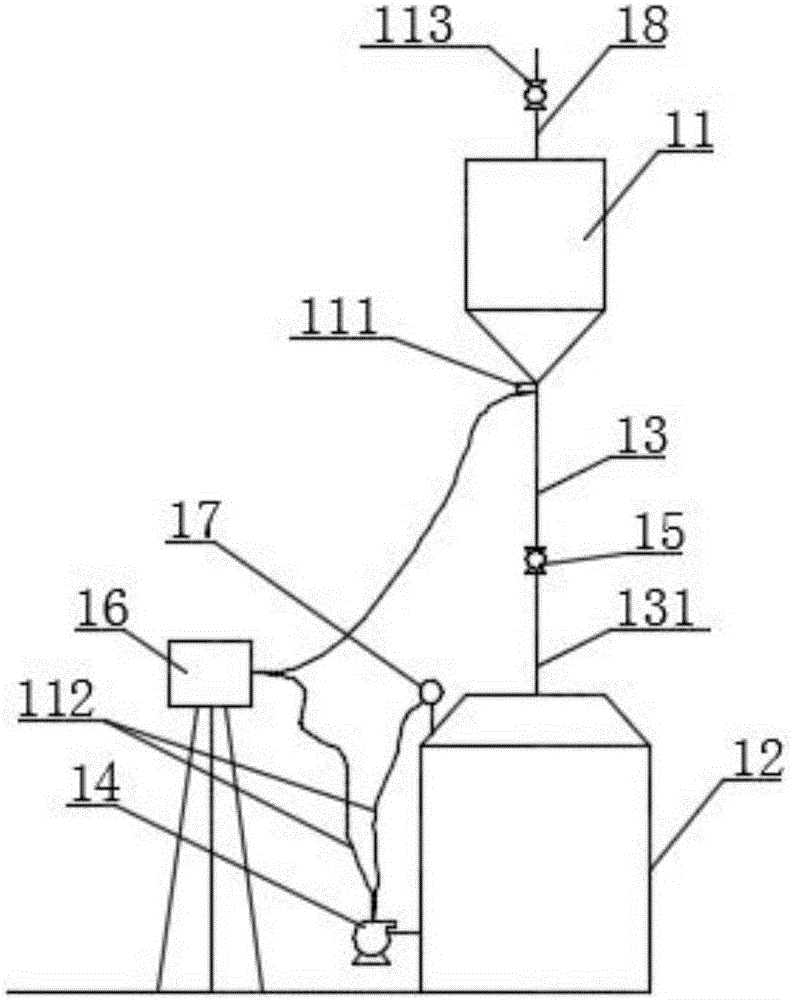

[0045] see figure 1 Shown, a kind of water-based paint automatic blanking system provided by the invention comprises:

[0046] The metering tank 11 is used to store the quality of the liquid material to be mixed;

[0047] Reactor 12, used to provide a reaction space for the liquid material to be mixed;

[0048] Dosing pipe unit 13, used to communicate with the metering tank and the reaction kettle;

[0049] Vacuumizer 14, used to transport the liquid material to be mixed in the metering tank to the reaction kettle;

[0050] Electromagnetic valve 15 is used to realize the on-off of the metering tank and the reaction kettle;

[0051] Industrial computer 16, used to control the solenoid valve and the vacuum pump;

[0052] The pressure sensor 17 is used to measure the pressure in the reactor and transmit the measured pressure to the industrial computer.

[0053] In this embodiment, the reaction kettle communicates with the metering tank through the dosing pipe unit, the dosin...

Embodiment 2

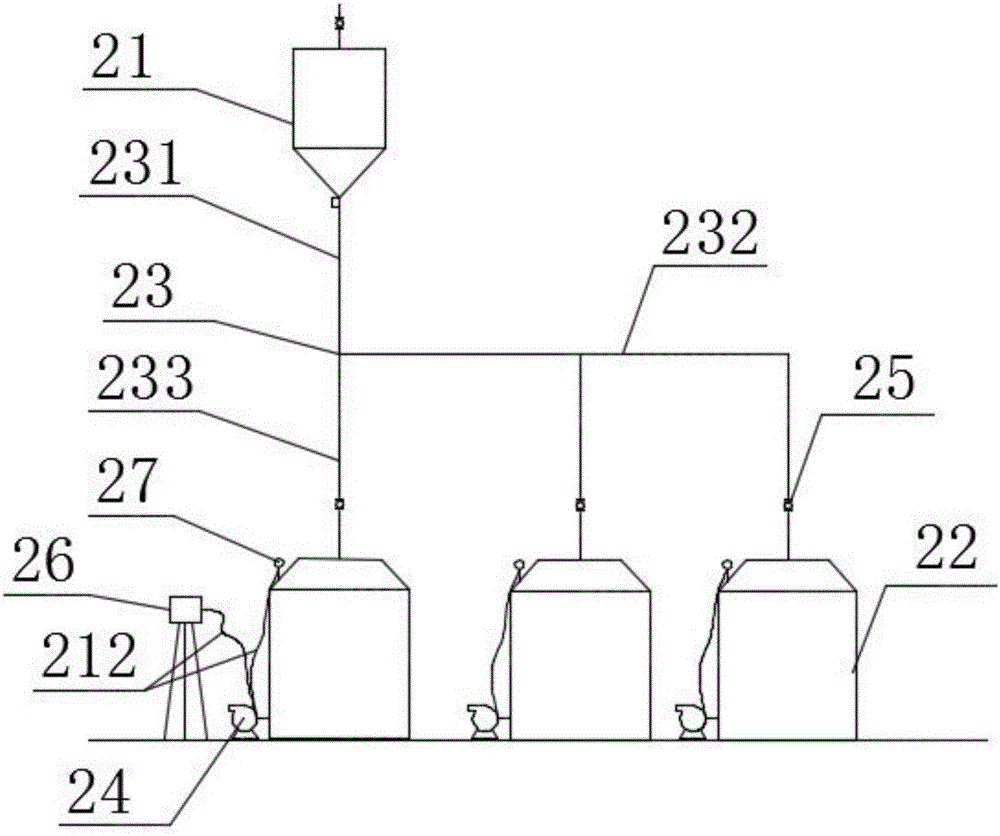

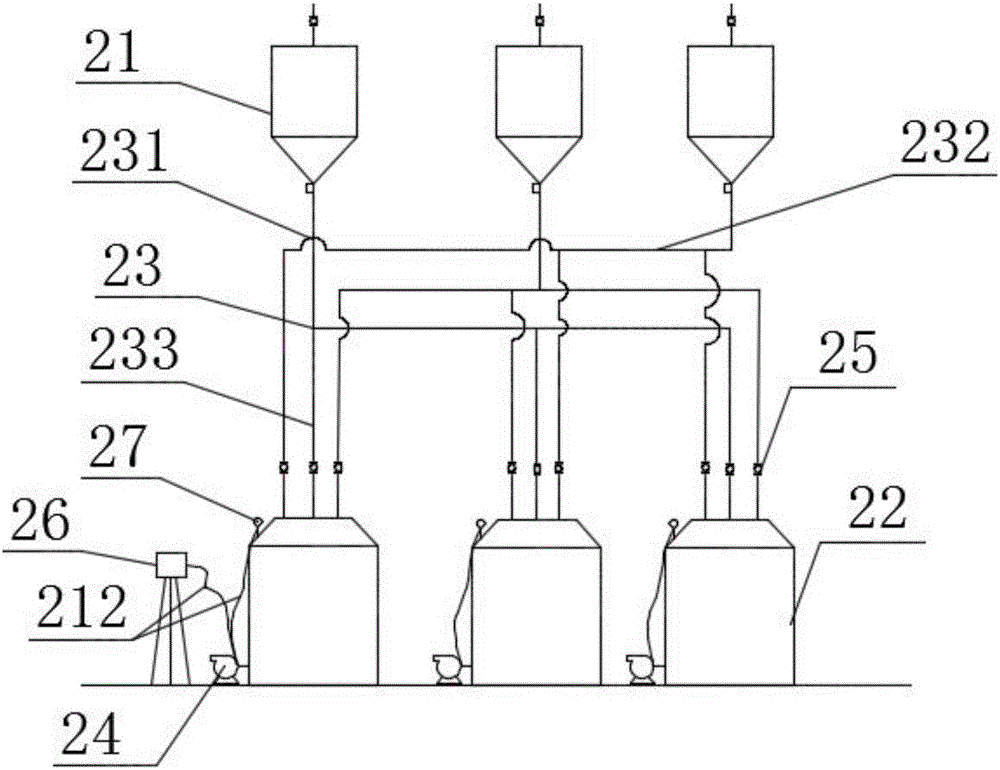

[0062] see figure 2 , image 3 As shown, the dispensing pipe unit 23 in this embodiment includes a primary pipe 231, a secondary pipe 232 and three tertiary pipes 233; each of the tertiary pipes 233 is provided with a solenoid valve 25, each of which The tertiary pipes 233 communicate with the primary pipe 231 through the secondary pipe 232, the primary pipe communicates with the liquid outlet of the metering tank 21, and one of the tertiary pipes communicates with one of the reaction pipes. The liquid inlet of kettle 22 is communicated, and a described metering tank is communicated with a plurality of described reaction kettles 22 through a described dispensing pipe unit 23; The tank is connected; in this embodiment, the electromagnetic valve 25 is connected to the industrial computer 26 by radio; the vacuum machine 24 and the pressure sensor are connected to the industrial computer 26 by wires 212 .

[0063] In this embodiment, a design in which one of the dosing pipe uni...

Embodiment 3

[0066] see Figure 4 , Figure 5 As shown, the dispensing pipe unit 33 in this embodiment includes three primary pipes 331, a secondary pipe 332 and a tertiary pipe 333; each of the primary pipes 331 is provided with the solenoid valve 35, Each of the primary pipes communicates with the tertiary pipe 333 through the secondary pipe 332, the tertiary pipe communicates with the liquid inlet of the reactor 32, and one of the primary pipes communicates with one of the tertiary pipes. The liquid outlet of metering tank 31 is communicated, and a described reaction kettle 32 is communicated with a plurality of described metering tanks 31 through a described dosing pipe unit 33; The reaction kettle is connected. In this embodiment, the solenoid valve 35 is connected to the industrial computer 36 by radio; the vacuum machine 34 and the pressure sensor are connected to the industrial computer 36 by wires 312 . This embodiment also includes a human-computer interaction device 38 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com