Roll paper screening and weight-balancing device as well as roll paper screening and weight-balancing method

A technology of counterweight device and roll paper, which is applied in the direction of sorting, etc., can solve the problems of increasing cost, affecting the weight of roll paper, boxed paper, and shortage of manufacturers, so as to save production cost, counterweight and screen quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

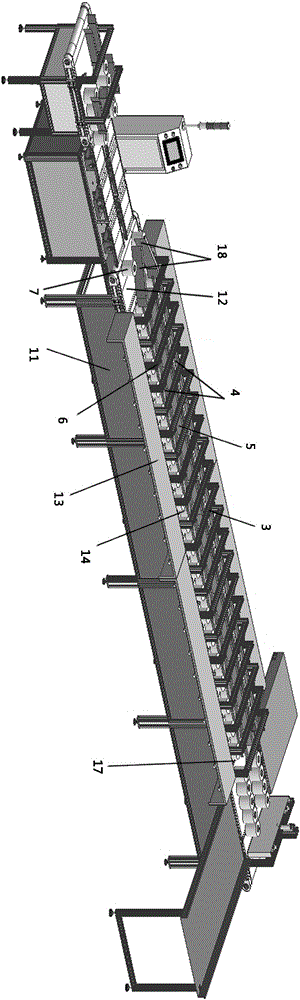

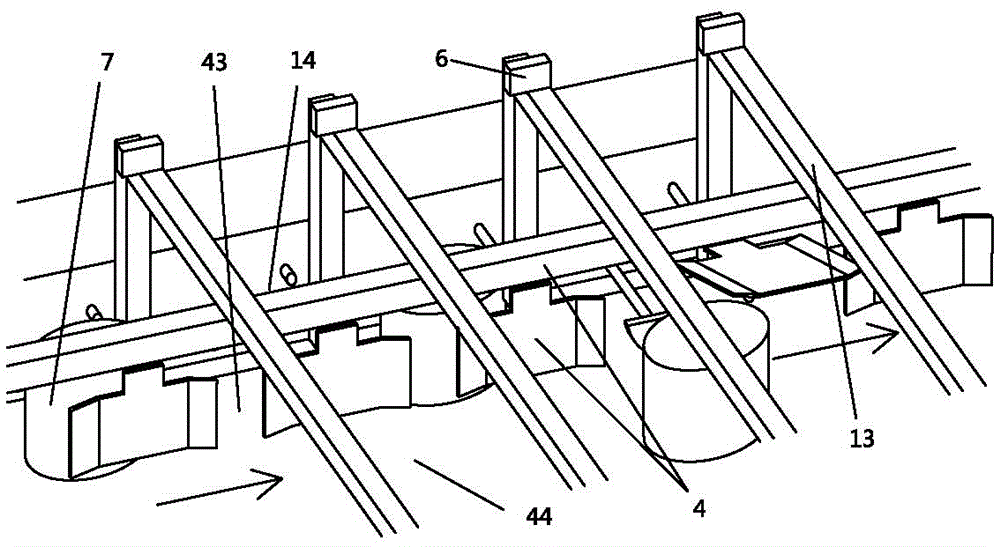

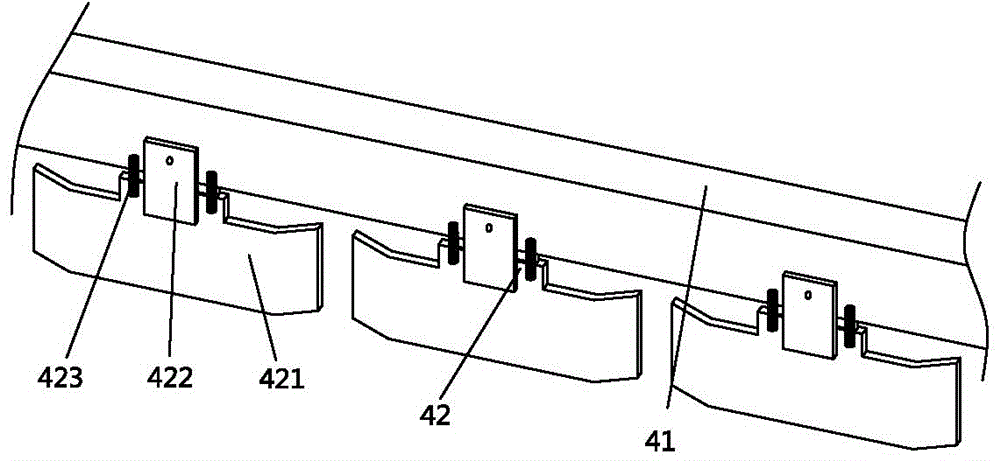

[0030] Such as Figure 1-5 As shown, the roll paper screening and counterweight device of the present invention includes a machine table 11, a central control module 2 and a conveyor belt 12 provided on the machine table 11. An upward boss 13 is provided on the side of the machine table 11. A number of movable fences 14 and brackets 3 are arranged on the inner side of the boss 13, and a fixed rod 17, the movable fences 14 and the brackets 3 are arranged in one-to-one correspondence; one movable fence 14 Only one roll of paper 7 is accommodated; the fixing rod 17 is located at the rear edge of the boss 13. Each bracket 3 is equipped with a monitoring and sensing structure 6 which is connected to the central control module 2 for monitoring whether the roll paper 7 enters the movable field 7. The monitoring and sensing structure 6 may include an optical fiber sensor or an infrared sensor, wherein the transmission rate of the optical fiber sensor is faster than that of the infrare...

Embodiment 2

[0044] Based on Example 1, the method for roll paper screening and counterweight, the roll paper screening and counterweight device is used for screening and counterweight:

[0045] Step S1: Set the requirement specifications of the next process roll paper 7 in the central control module 2: The total weight of 10 rolls 7 and 10 rolls 7 is 1200g.

[0046] Step S2: The roll paper 7 flows into the empty activity column 14 in sequence, and the central control module 2 stores the obtained roll paper 7 data into the corresponding data grid 21 at the same time.

[0047] Step S3: The monitoring sensor structure 6 detects that there is a roll of paper 7 in the active column 14, and the blocking lever 15 corresponding to the active column 14 is controlled by the central control module 2 and extends inward; repeat step S2.

[0048] Step S4: When the number of rolls 7 in all the active fields 14 is ≥10 respectively, and there are 10 rolls of paper 7 in the active field 14 with a weight of 1200g, t...

Embodiment 3

[0053] Such as Image 6 As shown, based on Example 1, the method of roll paper screening and counterweight, the roll paper screening and counterweight device is used for screening and counterweight:

[0054] Step S1: Set the requirements of the next process roll paper 7 in the central control module 2: The total weight of 10 rolls 7 and 10 rolls 7 is 1200g, from the two waiting areas (line A, line B) ) Screen 5 each.

[0055] Step S2: The roll paper 7 sequentially flows into the empty activity column 14, and the central control module 2 stores the obtained roll paper 7 data into the corresponding data grid 21;

[0056] Step S3: The monitoring sensor structure 6 detects that there is a roll of paper 7 in the active column 14, and the blocking lever 15 corresponding to the active column 14 is controlled by the central control module 2 and extends inward; repeat step S2;

[0057] Step S4: When the number of rolls 7 in the activity column 14 corresponding to row A and row B is ≥5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com