Fine dried noodle maker adopting automatic management technology

An automatic management and noodle machine technology, applied in application, food preparation, food science and other directions, can solve the problem of difficulty in reducing labor costs, and achieve the effect of reducing labor cost input and labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

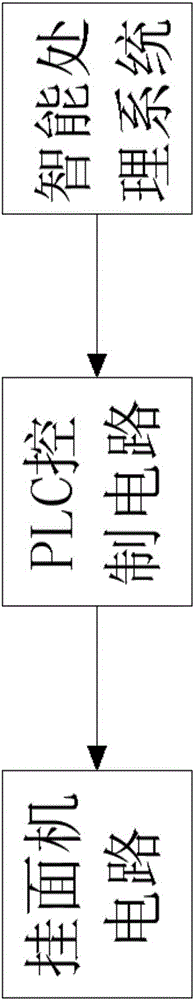

[0018] A noodle machine adopting automatic management technology, such as figure 1 , figure 2 As shown, it includes the mechanical structure of the noodle machine, the noodle machine circuit that controls the operation of the noodle machine mechanical structure, the PLC control circuit for controlling the noodle machine circuit, and the intelligent processing system that uses intelligent processing technology to control the PLC control circuit. The intelligent processing system is connected with a PLC control circuit, and the PLC control circuit is connected with a noodle machine circuit, and the noodle machine circuit is arranged on the mechanical structure of the noodle machine.

[0019] The staff set parameters according to the information stored in the intelligent processing system and according to the requirements of the noodles to be produced (such as the amount of water added, the amount of noodles added, the amount of auxiliary materials required, and the speed of mix...

Embodiment 2

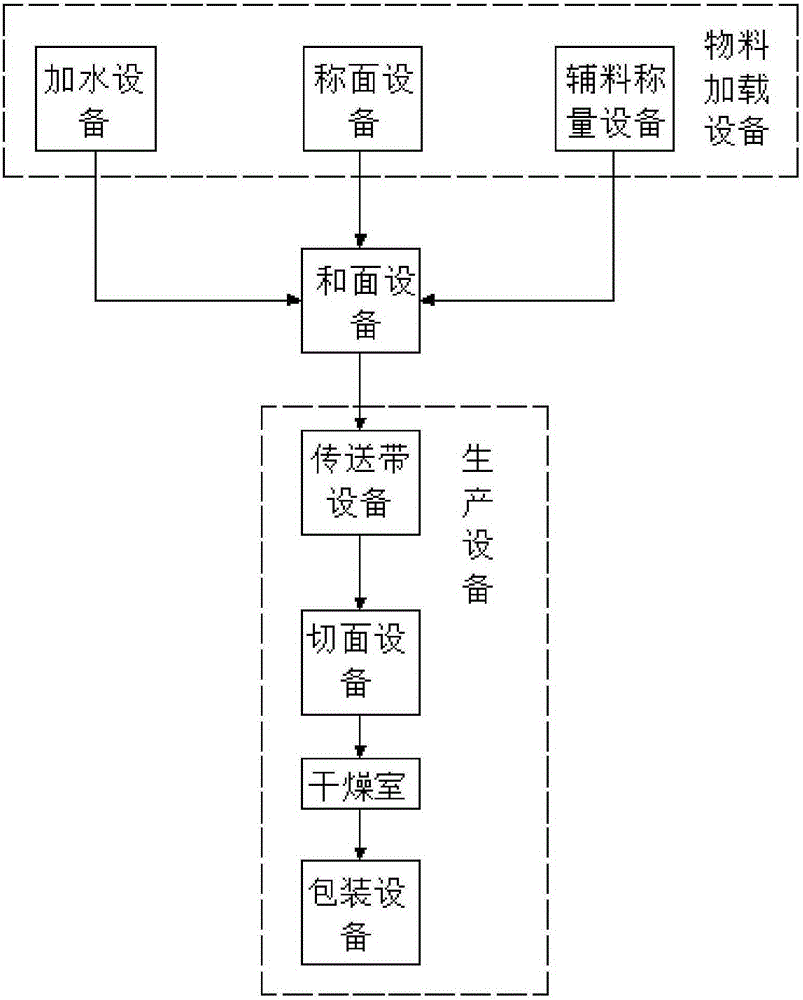

[0021] This embodiment is further optimized on the basis of the above-described embodiment. For further better realization of the present invention, the required vermicelli can be produced according to quality requirements, such as figure 1 , figure 2 As shown, the following structure is specially provided: the mechanical structure of the noodle machine includes material loading equipment, dough mixing equipment and production equipment, the material loading equipment is connected with the dough mixing equipment, the dough mixing equipment is connected with the production equipment, and the The noodle circuit is set on the material loading equipment, the noodle mixing equipment and the production equipment.

[0022] Among them, the material loading equipment is used for weighing materials and loading them into the kneading equipment for kneading;

[0023] Dough mixing equipment, the materials loaded in it are kneaded according to the preset parameters and formed into the req...

Embodiment 3

[0026] This embodiment is further optimized on the basis of the above embodiments. In order to further better realize the present invention, the raw materials of dried noodles are weighed and loaded according to the formula requirements, and then the required dough embryos are produced for further production into dried noodles. Such as figure 1 , figure 2 As shown, the following structure is specially set up: the material loading equipment includes water adding equipment, noodle weighing equipment and auxiliary material weighing equipment, and the water adding equipment, noodle weighing equipment and auxiliary material weighing equipment are all connected to the noodle mixing equipment.

[0027] The PLC control circuit uses the control parameters and commands set by the intelligent processing system to control the water adding equipment, noodle weighing equipment and auxiliary material weighing equipment. Inside; water adding equipment, according to the formula requirements ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com