Steel structure punching device

A drilling device and steel structure technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of poor product quality, low production efficiency, etc., and achieve the goal of reducing electric shock Hazards, reduced occupancy, increased flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

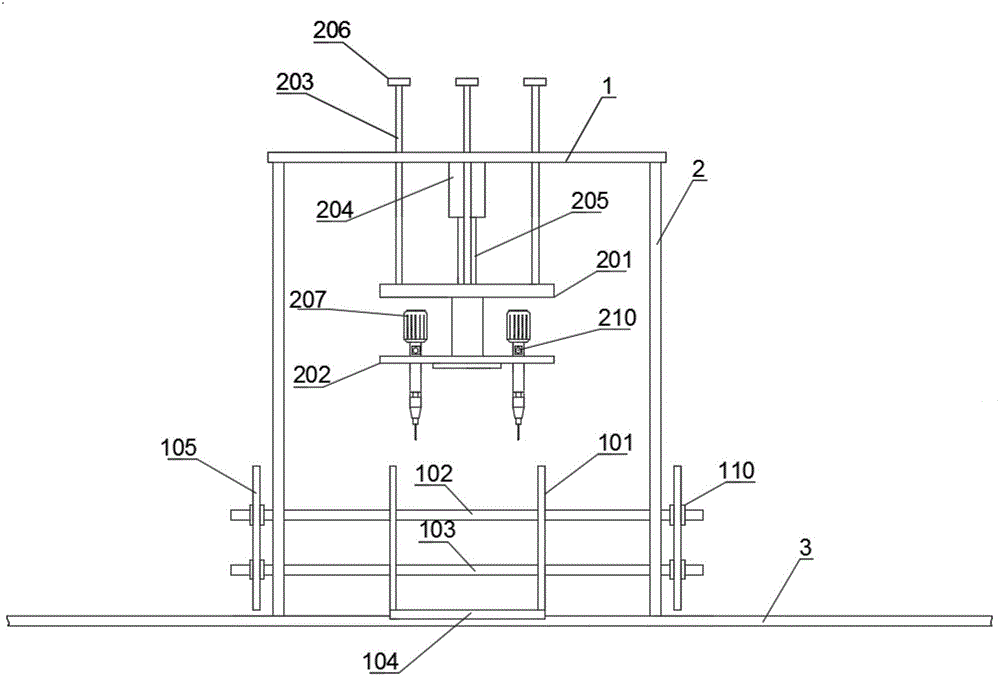

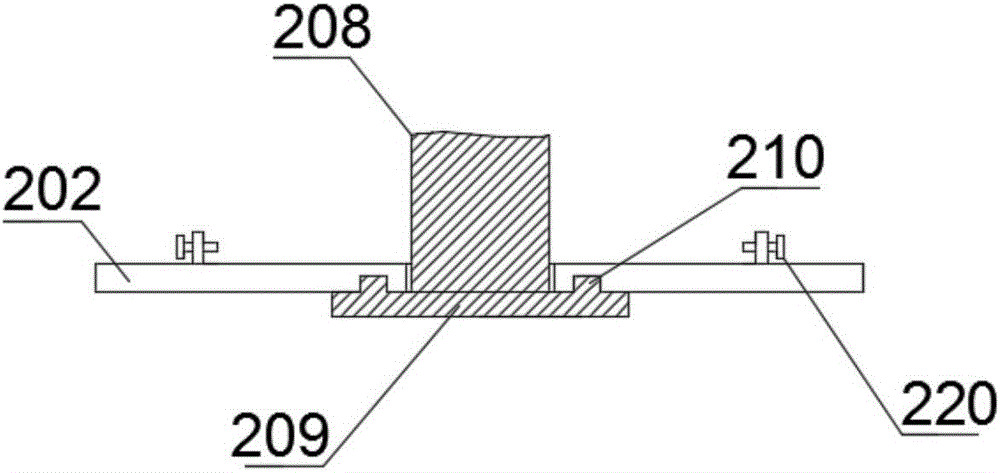

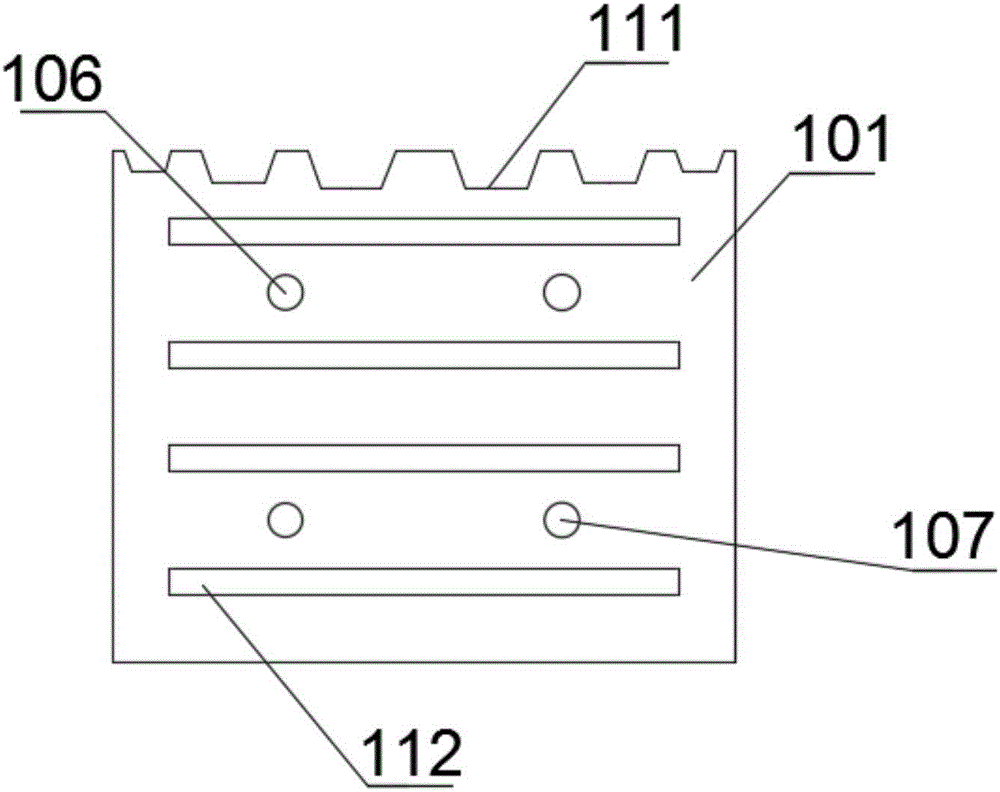

[0016] Such as Figure 1-5 As shown, the present embodiment provides a steel structure punching device, including a punching device, a working platform, a top plate 1, a column 2 and a slide rail 3; the top plate 1 is fixed on the ground through the column 2; the punching The device includes a mounting plate 201, a rotating plate 202, a sliding rod 203, a lifting column 204 and four punchers 207; the lifting column 204 is fixed on the bottom of the top plate 1, and its piston rod 205 is connected to the mounting plate 201; the sliding rod The upper part of 203 is movably installed on the top plate 1 through the slide hole arranged on the top plate 1, and the bottom of the slide bar 203 is fixedly connected with the mounting plate 201, and the top of the slide bar 203 is provided with a limit block 206; the bottom of the mounting plate 201 A connecting column 208 is provided, and a horizontal plate 209 is provided at the bottom of the connecting column 208; an annular slide rai...

Embodiment 2

[0018] Such as Figure 1-5 As shown, the present embodiment provides a steel structure punching device, which is different from Embodiment 1 in that a plurality of strip-shaped holes 112 are provided on the side walls of the vertical fixed plate 103 and the movable plate 105; A positioning bolt 220 for fixing the position of the cylindrical shell is provided at the mounting hole of the rotating disk 202; the positioning bolt 220 is installed on the rotating disk 202 through a vertical plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com