Process method of angle steel profiling cutter

A process method and cutting method technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as increased difficulty, low efficiency, and poor cutting quality, so as to reduce the error rate of blanking and reduce the difficulty of operation , the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

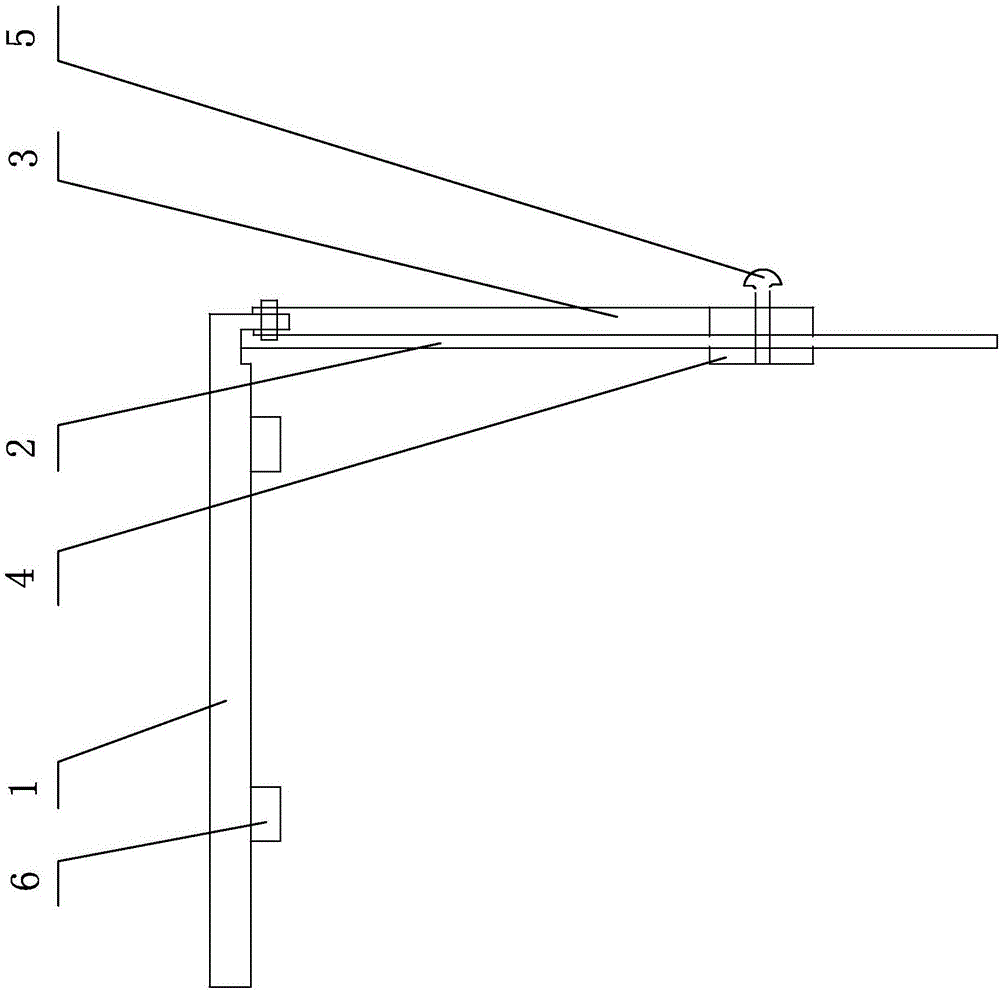

[0030] The technical solution of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings (mainly used for cutting the angle steel 7).

[0031] The process method of the angle steel profiling cutter of the present invention includes the manufacturing process of the cutter and the cutting method of the cutter.

[0032] 1. The production process of the cutter:

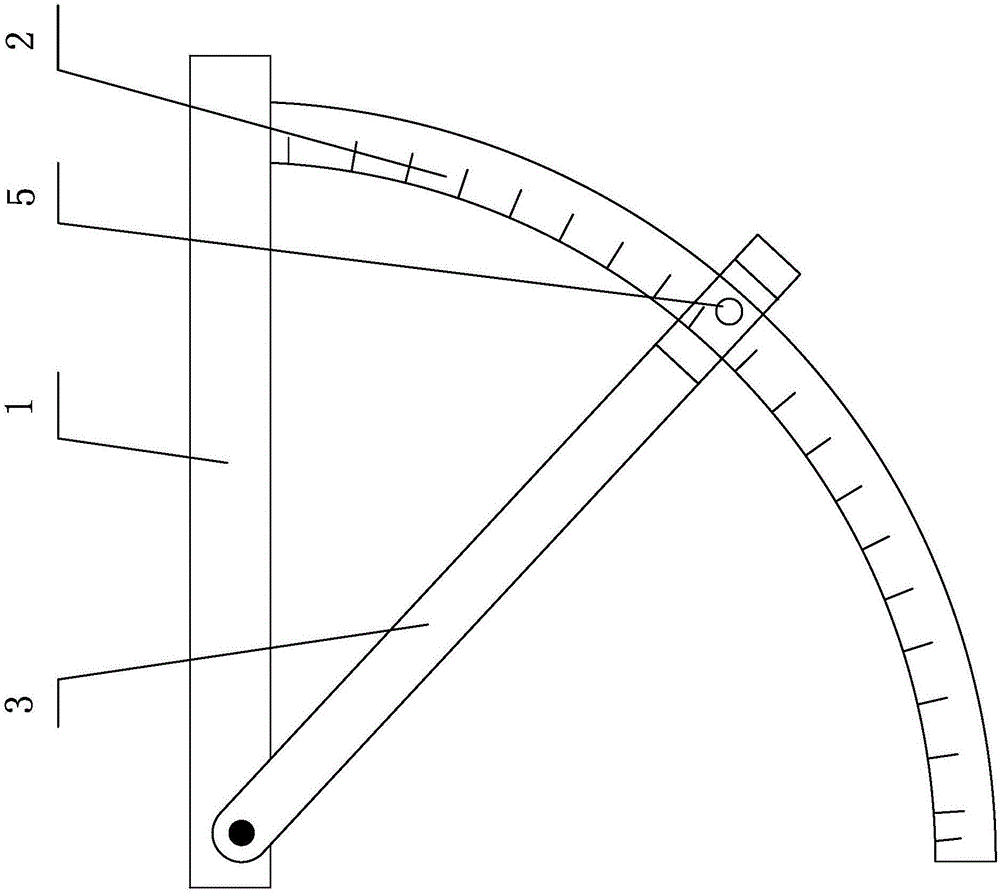

[0033] The cutter is composed of a right-angle base plate 1, an angle ruler 2 and a cutting ruler 3 and other parts.

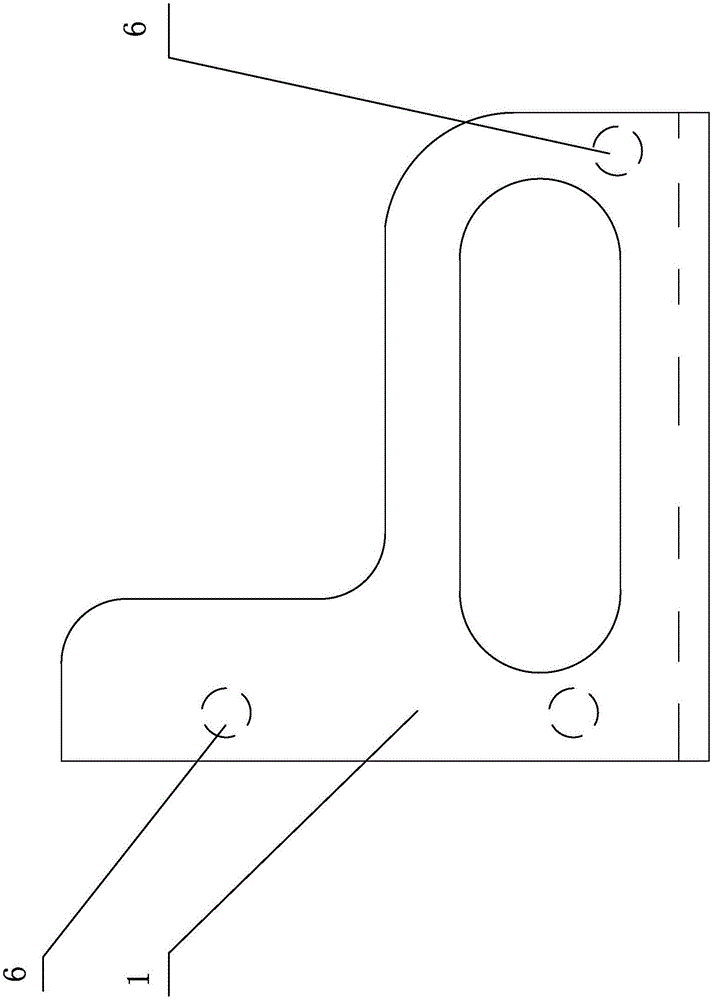

[0034] The structure of the cutter is that the right-angle substrate 1 is a rectangular plate, and a vertical ruler and a horizontal ruler are formed by incisions on the upper right thereof, and the intersection of the vertical ruler and the horizontal ruler forms a right angle. The position and the inner side of the horizontal ruler position are respectively provided with a pad 6, and the three pads 6 have the same thickness, as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com