Linear cutting clamp of gear

A wire cutting and fixture technology, which is applied in the direction of manufacturing tools, electric processing equipment, metal processing equipment, etc., can solve the problems of poor pertinence and few fixtures, and achieve the effects of wide application range, simple tightening and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

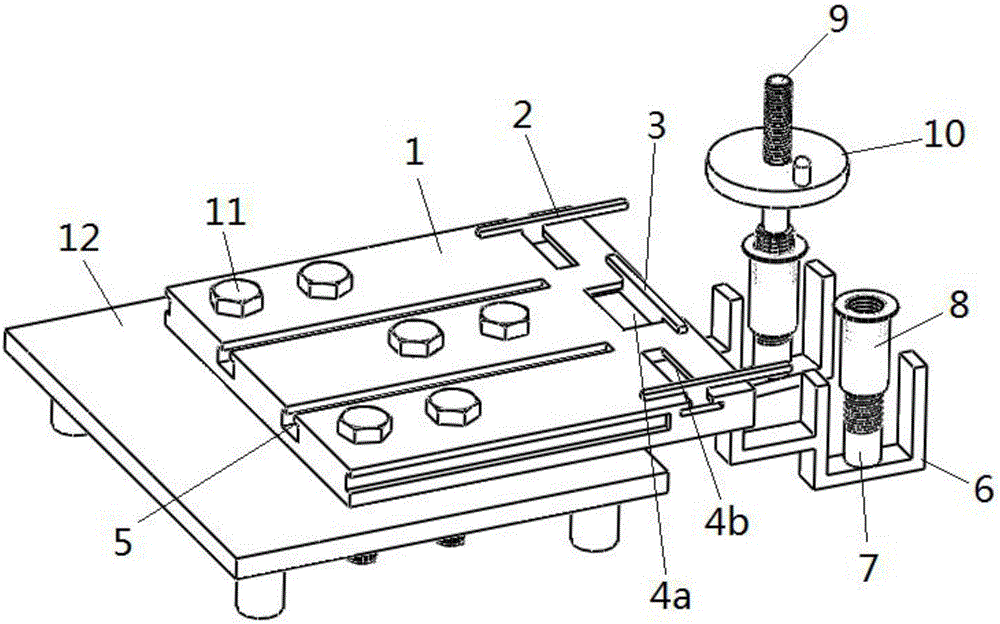

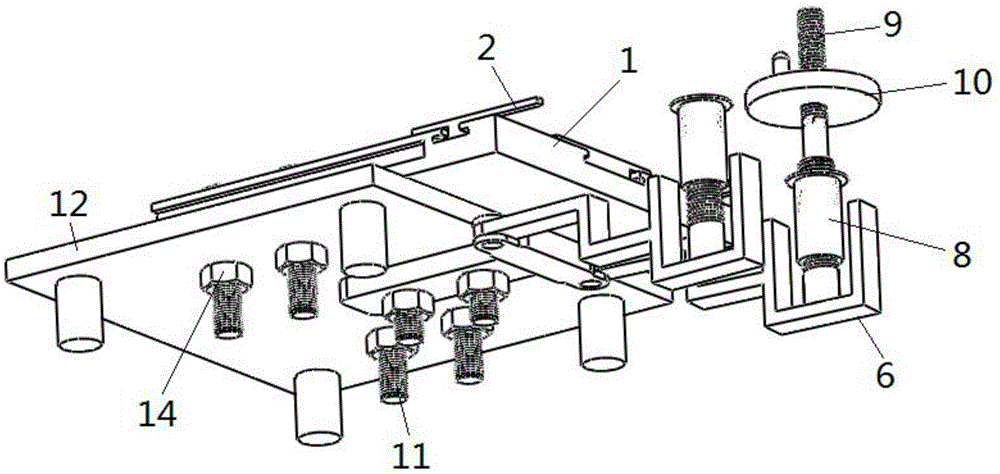

[0027] see figure 1 , a wire cutting fixture for gears, comprising: a base 1, a positioning plate I2, a positioning plate II3, a pair of rotating supports 6, a lead screw I7, a support column 8, a lead screw II9, a pressure plate 10, a support 12, and a fixing seat 13;

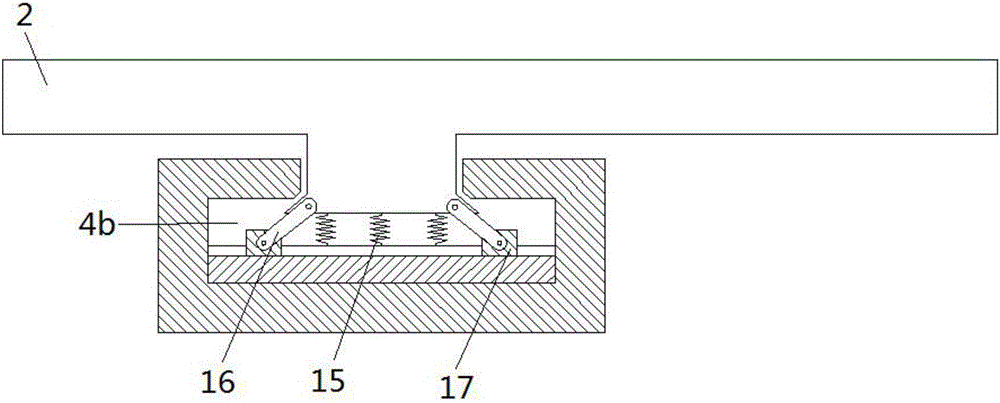

[0028] There is a chute Ⅰ4a at the front end of the base 1. The chute Ⅰ4a is short and used to install the positioning plate Ⅱ3. The positioning plate Ⅱ3 can move back and forth in the chute, and can provide different positioning distances for workpieces of different sizes; The two sides of the slot I4a are respectively provided with transverse chute I4b, and the chute I4b is elongated, which are respectively used to install the positioning plate I2, and the positioning plate I2 can slide in it to match workpieces of different sizes; the horizontal chute There are several long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com