Automatic welding device of nut

An automatic welding and nut technology, which is applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of dangerous and unstable placement of nuts, and achieve the effect of improving welding quality, reducing personal injury, and reducing the incidence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] specific implementation plan

[0017] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

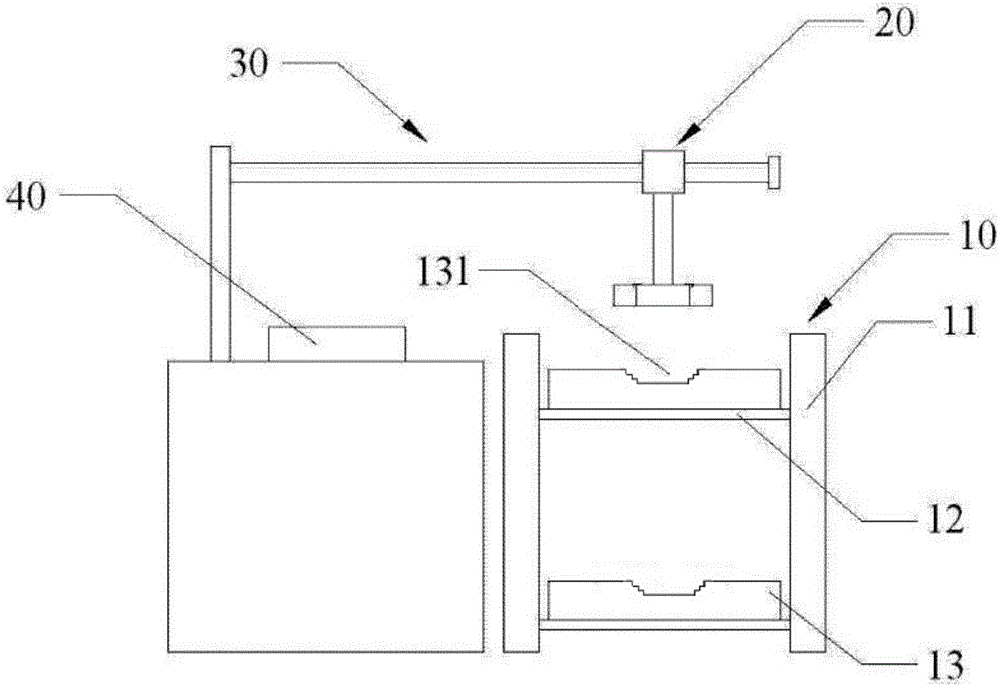

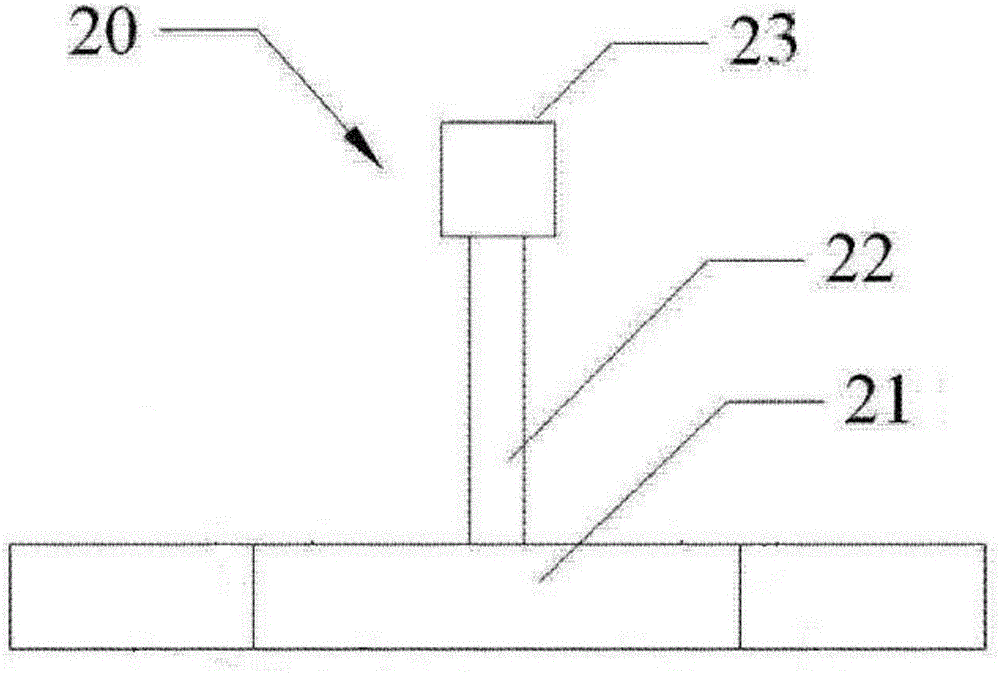

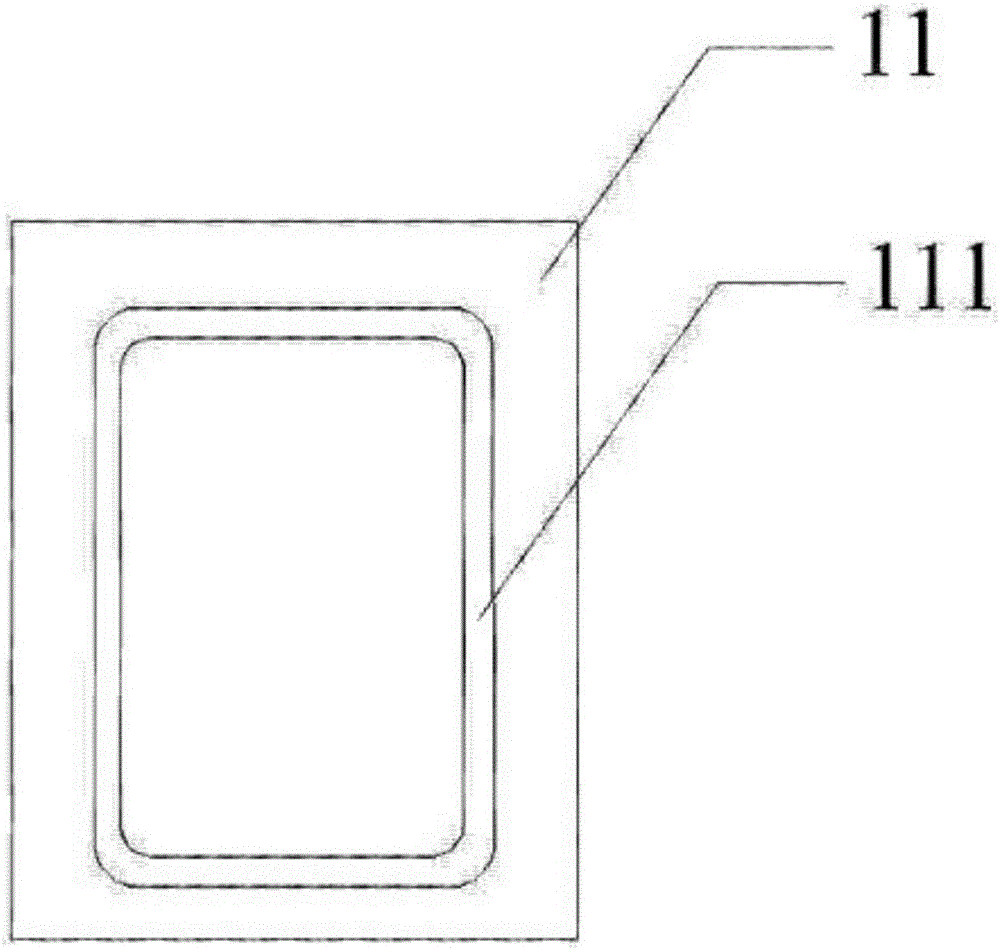

[0018] as attached Figure 1-3 The shown nut automatic welding device includes a feeding device 10, a magnetic adsorption device 20, a bracket 30 and a projection welding machine 40. The adsorption device 20 and the bracket 30 are slidably connected by a slider 23, and the bracket 30 is used to support the adsorption. The device 20, the projection welder 40, is used to weld the nuts. The feeding device 10 includes: two columns 11, a plurality of horizontal supporting plates 12 and nut placing plates 13, the placing plates 13 are located above the horizontal supporting plates 12, and there are preferably 2-4 placing plates 13. The opposite surfaces of the two columns 11 are provided with guide rails 111 , the horizontal support plate 12 is located in the guide rails 111 , and the solar photov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com