Assembling device of radiating piece

A technology for assembling devices and heat sinks, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem that pins and heat sinks cannot be assembled with multiple heat sinks at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

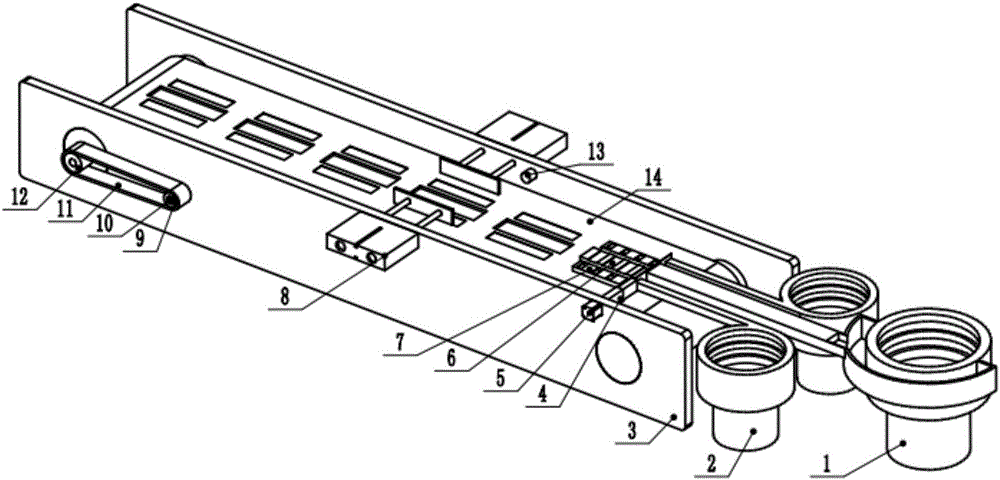

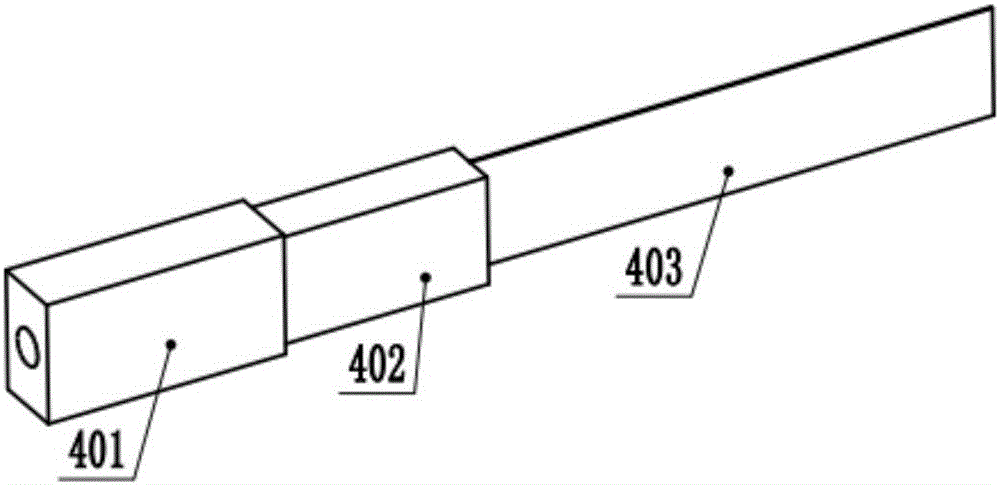

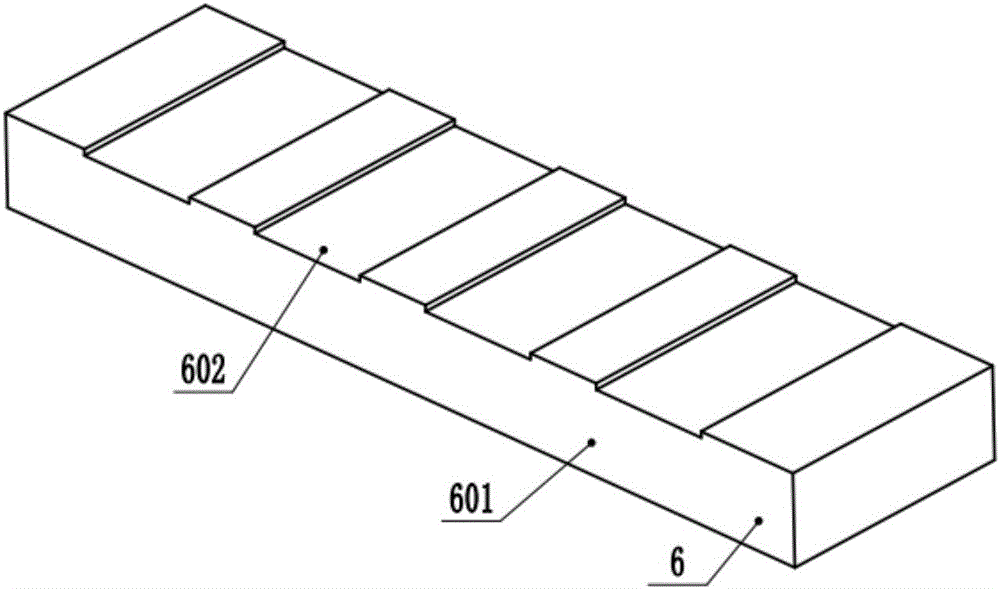

[0019] A heat sink assembly device is composed of a heat sink vibrating plate 1, a pin vibrating plate 2, a conveyor belt bracket 3, a telescopic device 4, a telescopic motor 5, a telescopic cylinder 8, a main transmission wheel 9, a transmission motor 10, a timing belt 11, Composed of transmission wheel 12, camera 13 and conveyor belt 14, the number of said conveyor belt bracket 3 is two, and heat sink positioning block 6 and pin positioning block 7, and said conveyor belt 14 includes conveyor belt body 141, Conveyor belt pin positioning block groove 142 and conveyor belt cooling fin positioning block groove 143 structure, the number of the pin vibrating plate 2 is two, the number of the telescopic cylinder 8 is two, the The output port of the heat sink vibrating plate 1 is connected to the heat sink positioning block 6, the output port of the pin vibration plate 2 is connected to the pin positioning block 7, the conveyor belt 14 is installed on the conveyor belt bracket 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com