Clamp used for turning of threads of perpendicularly intersecting shafts

A vertical intersection and thread technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high maintenance and maintenance costs, small use range, long processing cycle, etc., to improve processing quality and production. Efficiency, the effect of reducing the difficulty of clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

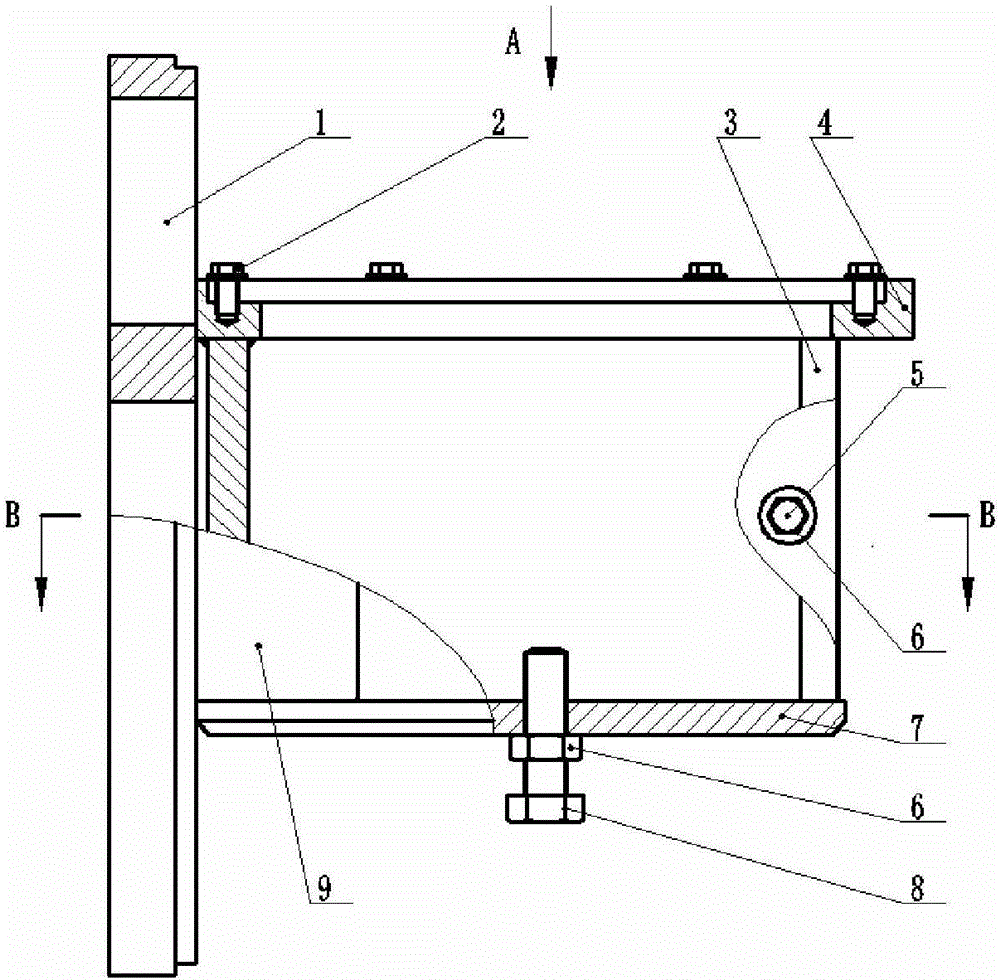

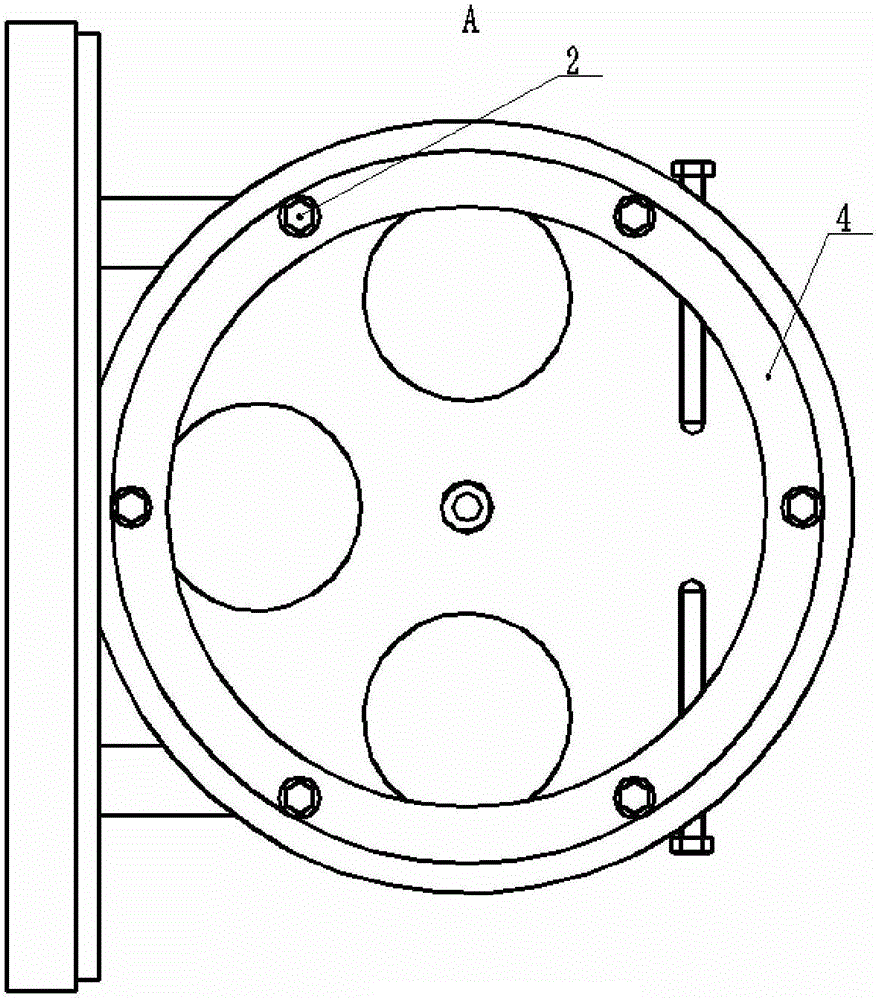

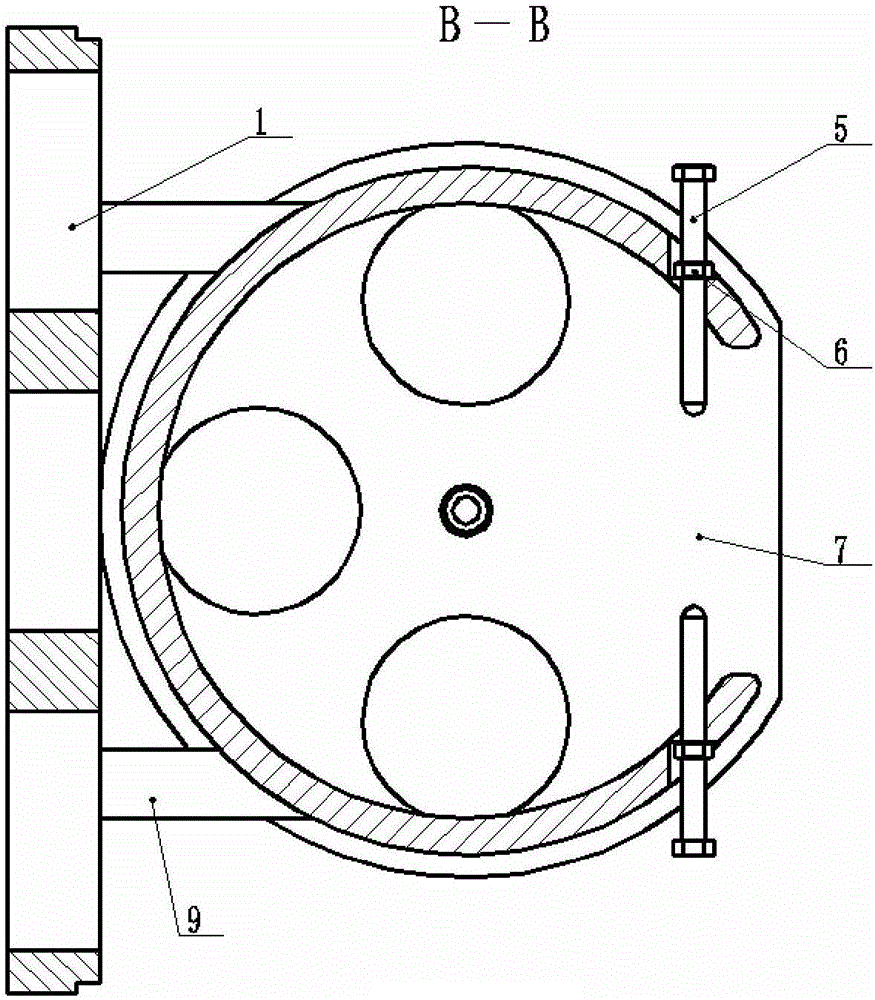

[0027] This embodiment is a fixture for machining vertical intersecting shaft threads on a horizontal lathe, including a clamping plate 1 , a ring body 3 , a positioning ring 4 , two rib plates 9 , and a bottom plate 7 . The two ribs 9 are fixed on one surface of the clamping plate 1, and the arc surfaces of the two ribs jointly form the support surface of the torus, so that the circumferential surface of the torus 3 is aligned with the two ribs. The arc surfaces of the plates are in contact with and fixed by welding; the opening on the circumference of the ring body is located between the two rib plates and is far away from the clamping plate. The connecting surface of the locating ring 4 circumferential surface is in contact with the surface of the clamping plate and fixed by welding; the lower surface of the locating ring is in contact with the upper end surface of the toroid and fixed by welding; the locating notch on the upper surface of the locating ring is used for for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com