Cutting method

A cutting method and cutting machine technology, which are applied in metal processing machinery parts, maintenance and safety accessories, measuring/indicating equipment, etc., can solve problems such as bullet wounding, thin wires are easy to be inserted into workpieces, and thin wires are broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

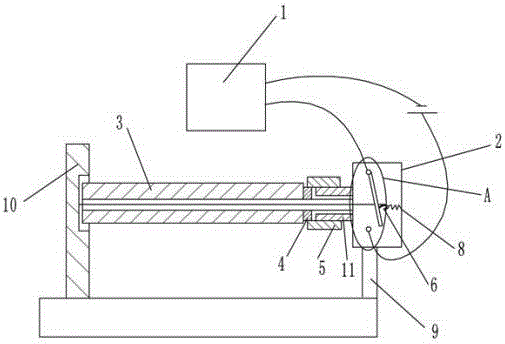

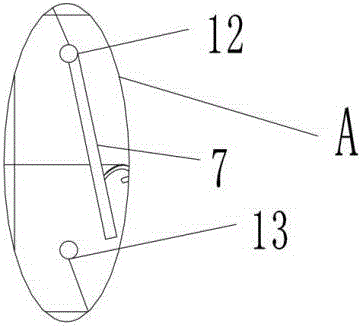

[0016] The reference signs in the drawings of the description include: cutting machine body 1, control box 2, paraffin plate 3, metal sleeve 4, rotating cover 5, hook 6, connecting rod 7, spring 8, first bracket 9, second bracket 10 , Hollow shaft sleeve 11, negative contact point 12, positive contact point 13.

[0017] A kind of cutting method in this scheme, comprises the following steps:

[0018] 1) Tighten the thin wire and tighten the switch, the switch is closed and energized, the paraffin plate is placed on the cutting line on the workpiece, the cutting machine is started, the cutting machine cuts at a speed of 10-12m / min, when the cutting piece of the cutting machine reaches the cutting line When cutting the wire, the cutting piece first cuts off the upper part of the paraffin board, then cuts off the insulating wire, the switch springs back, the circuit is disco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com