LPI fuel system and return fuel minimizing method

A minimization, fuel oil technology, applied in the direction of charging system, condensed fuel collection/return, oil supply device, etc., to avoid the increase of pump noise, lower cost, and avoid the effect of reduction

Inactive Publication Date: 2013-12-04

HYUNDAI MOTOR CO LTD

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0016] Therefore, conventional solutions cannot overcome various problems caused by LPI with a fuel return line system having an inner diameter of about 6mm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0101] According to the exemplary embodiment of the present invention, since the diameter of the fuel return line becomes smaller and the pressure regulator can be removed by reducing the return flow rate, it is possible to build the system at a relatively inexpensive cost.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

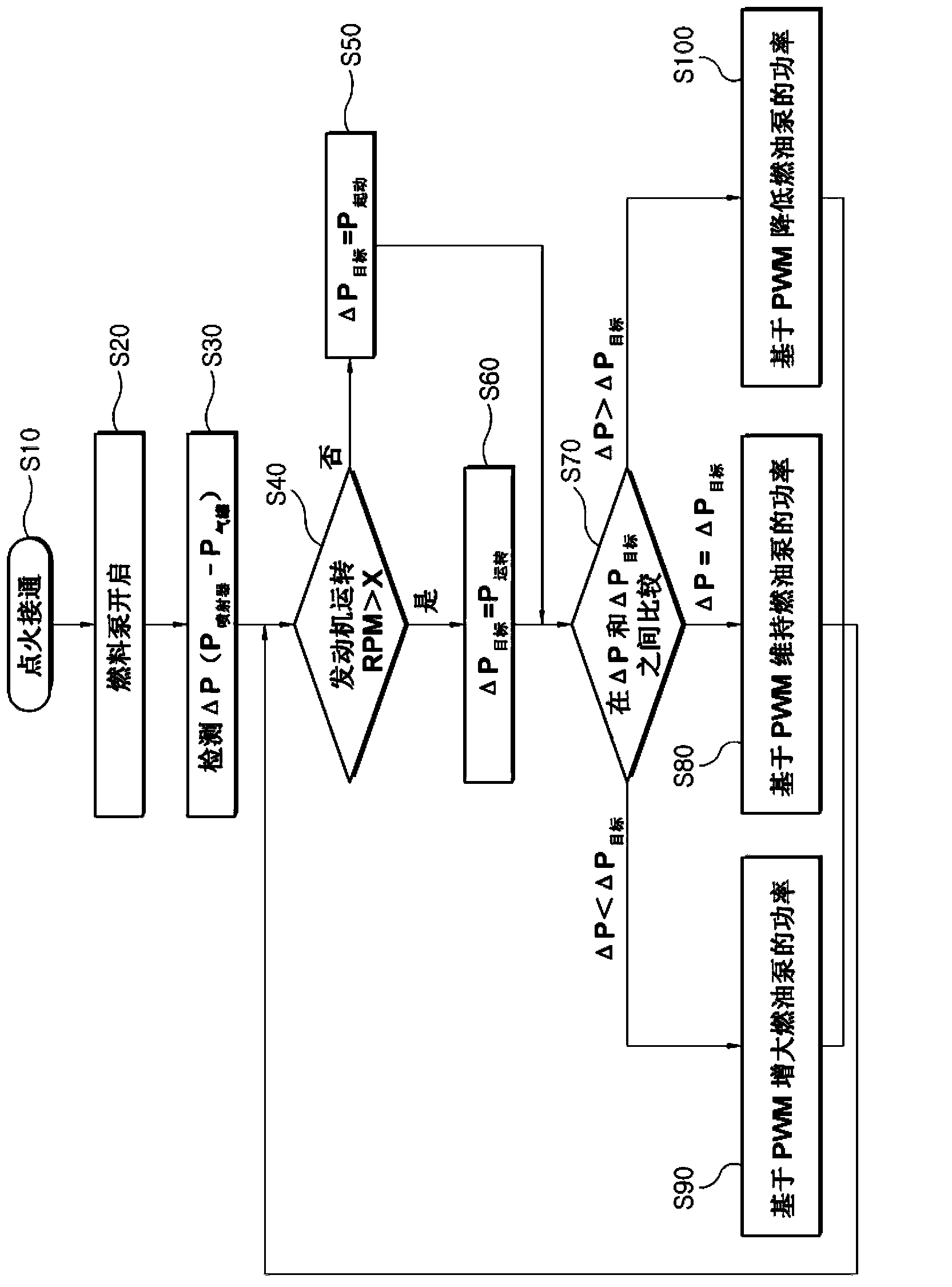

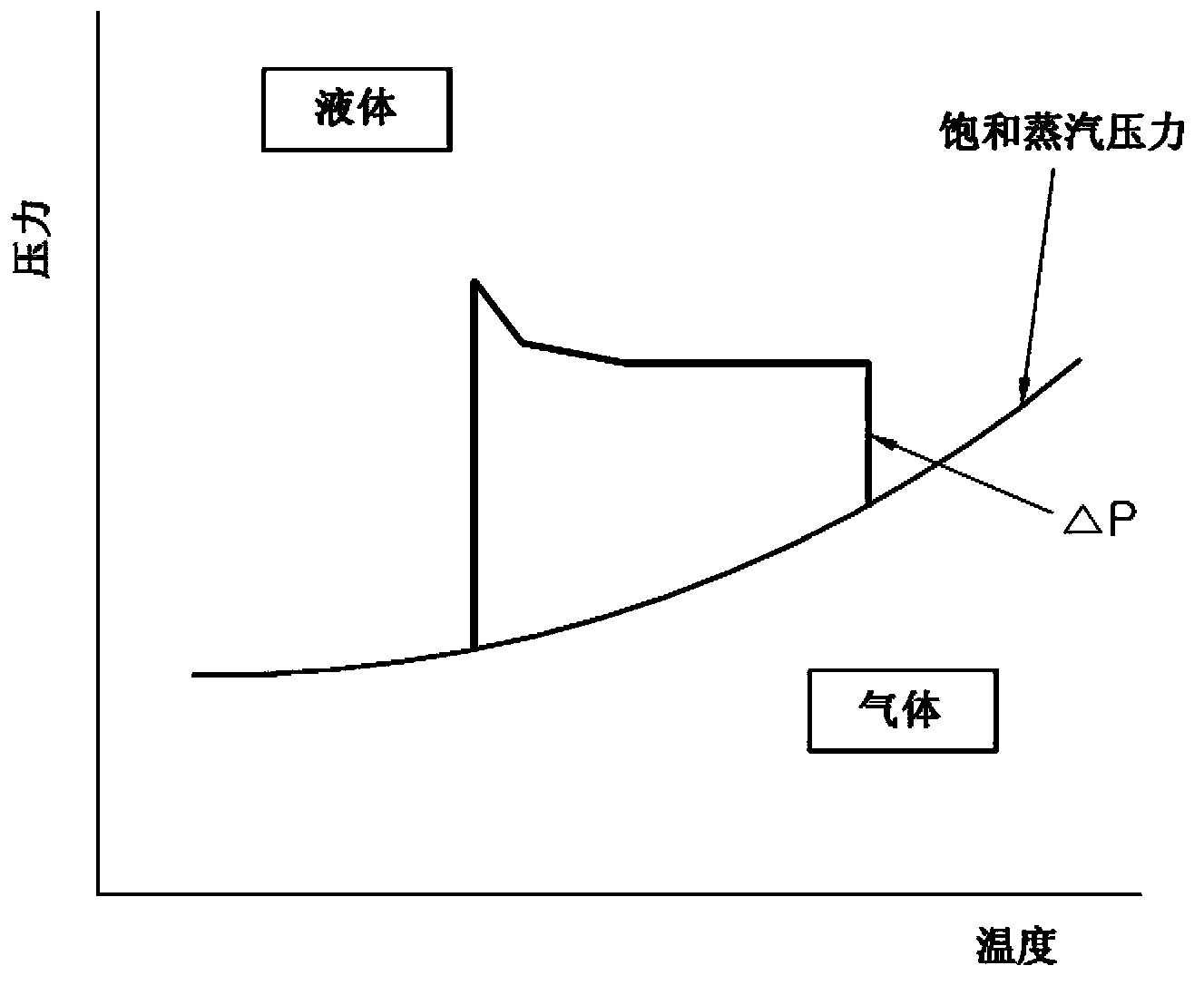

The invention discloses an LPI fuel system and a return fuel minimizing method. A return fuel minimizing logic of a fuel pump may include: after the fuel pump may be driven by detecting a key-on (IG ON) of an engine, the pressure difference [Delta]P (=the bombe fuel pressure P[bombe]-the fuel injection pressure P[injector]) may be detected, and then the target pressure [Delta]P[target] may be set to the engine starting pressure P[start] or at least four different engine running pressures P[running] so that the duty can be maintained, increased or decreased by controlling the fuel pump to optimize the flow rate discharged from the pump, considering the difference of the magnitude between the pressure difference [Delta]P and the target pressure [Delta]P[target], by which the return flow rate which may be affected by the engine heat and the air temperature, can be reduced.

Description

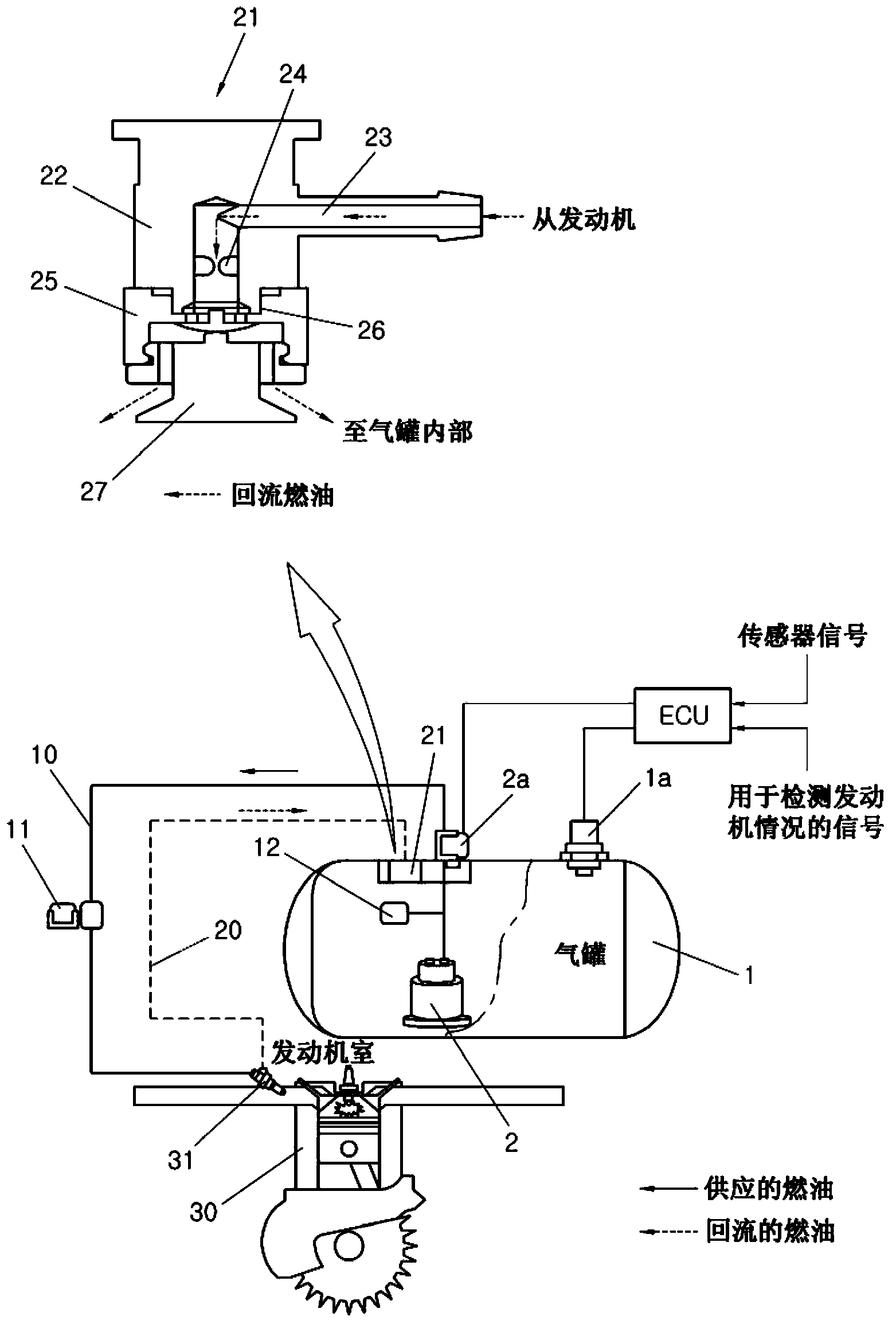

[0001] Cross references to related applications [0002] This application claims priority from Korean Patent Application No. 10-2012-0055239 filed on May 24, 2012, and the entire content of this application is incorporated herein for all purposes of this citation. Technical field [0003] The exemplary embodiment of the present invention relates to an LPI fuel system, and more specifically, to an LPI fuel system that adopts a method of minimizing return fuel, so that the operability of the fuel pump and the filling of the gas tank can be improved by the following means Performance: According to whether the engine is ignited or not, the fuel discharge speed is changed, and after the engine is started, the fuel discharge speed of the fuel pump is optimized through feedback control based on the engine load. Background technique [0004] Generally, the LPI (liquefied petroleum injection) engine is different from the LPG engine in that the fuel is supplied in a liquid state in the case o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F02M33/02F02M37/04

CPCF02D1/02Y02T10/32F02M21/0212F02D41/3082F02D2200/0602F02M21/02F02M37/00F02M51/02

Inventor 咸昌昊

Owner HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com