Movable platform mechanism with ball screw connected with gear and rack in series

A technology of rack and pinion and ball screw, which is applied in the field of robotics, can solve the problems of limited application range and inflexible movement of the movable platform, and achieve the effect of small deflection angle and large deflection angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

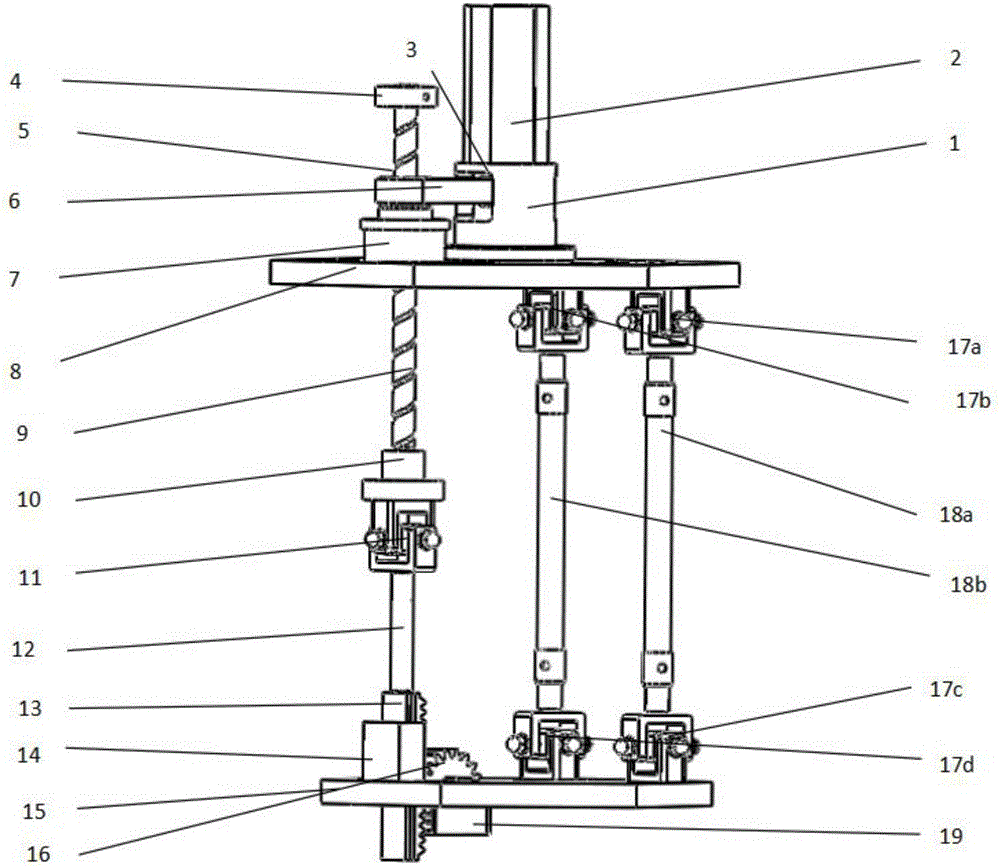

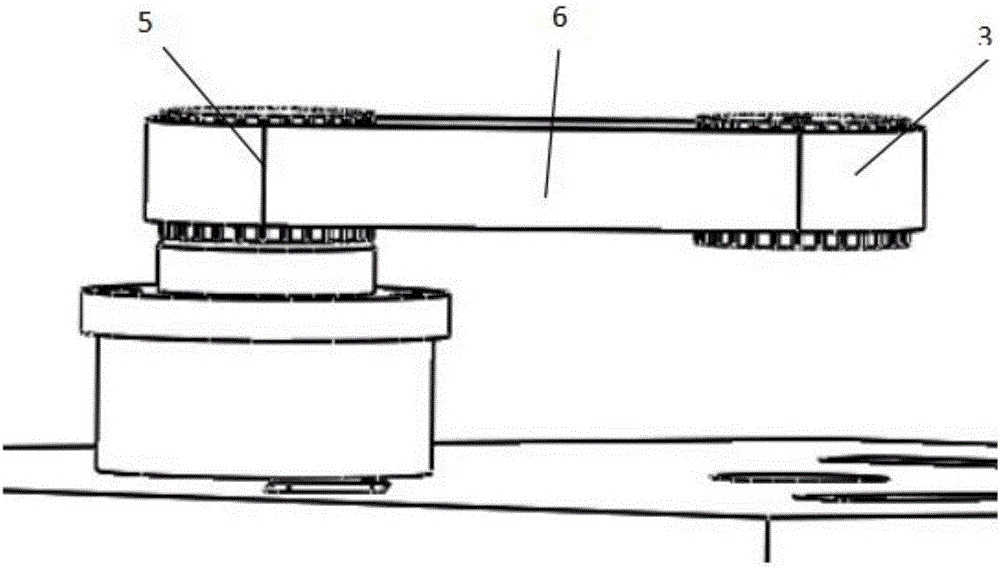

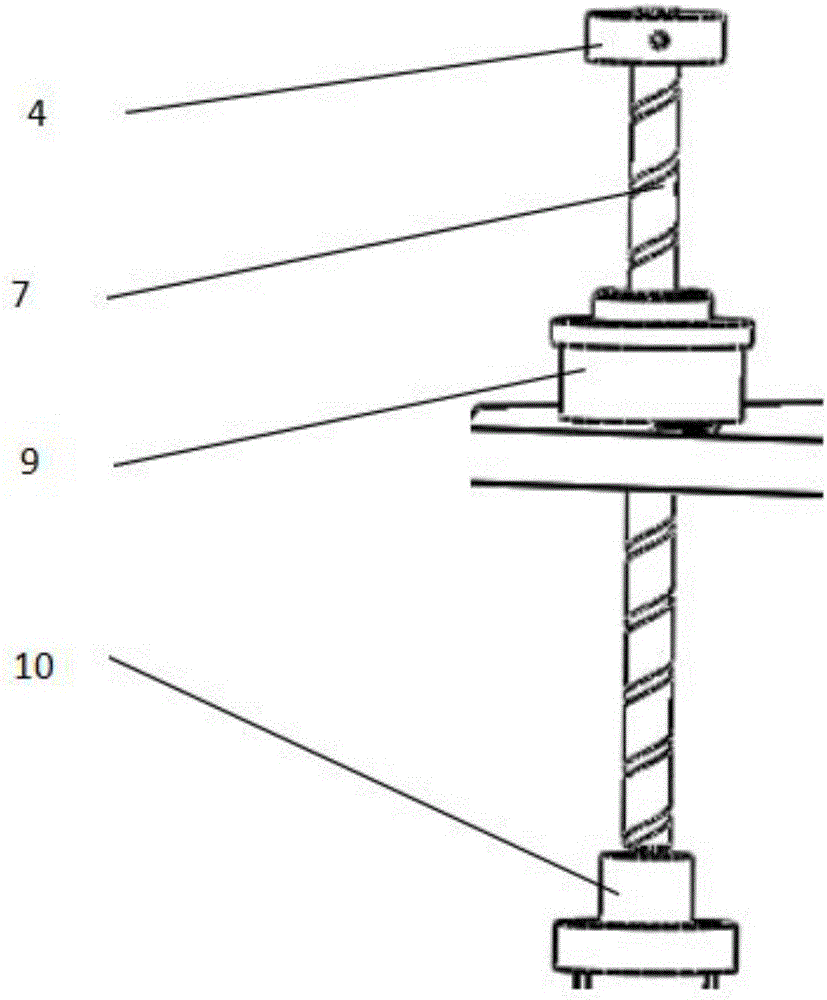

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a ball screw type moving platform mechanism includes a synchronous belt mechanism, a ball screw mechanism, a rack and pinion mechanism, an upper moving platform, a lower moving platform, a moving platform connecting rod, etc., and the upper and lower moving platforms, the screw and the gear The bar connecting rod and the moving platform connecting rod form a closed-loop mechanism, and the lengths of the two moving platform connecting rods are the same.

[0018] Such as figure 1 , figure 2 , image 3 As shown, the synchronous belt pulley 5 is connected to the inner ring of the lead screw nut 7, the axes of the synchronous belt pulley 3 and the synchronous belt pulley 5 are parallel and the end faces are on the same plane parallel to the upper moving platform 8, and the synchronous belt mechanism is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com