Photoresponsive polymer optical fiber and preparation method and application thereof

A photoresponse, polymer technology, applied in cladding fibers, optical waveguides, optical waveguide coupling, etc., can solve the problems of rising optical loss coefficient, limited applications, and inability to precisely control the distribution of gold nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

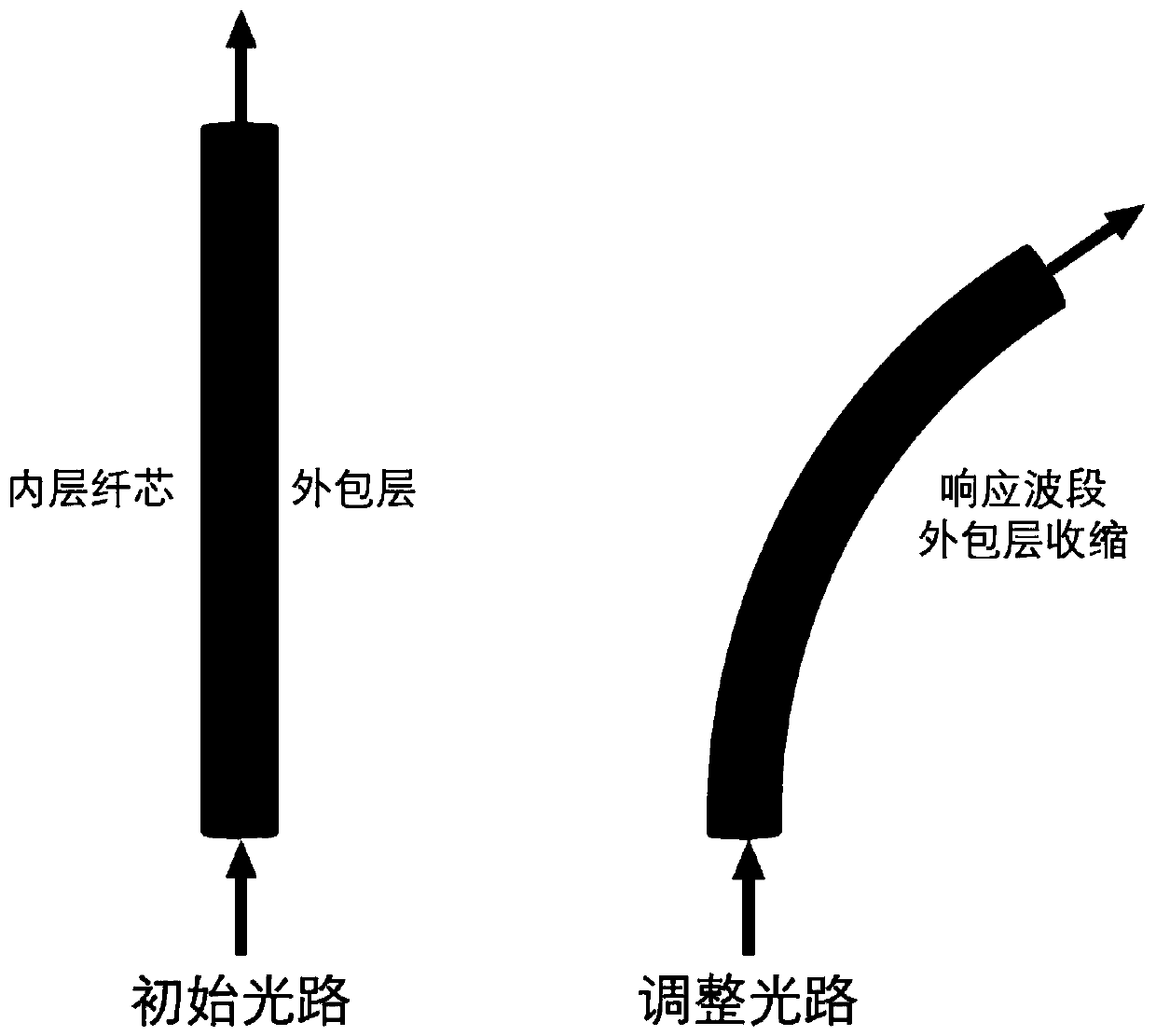

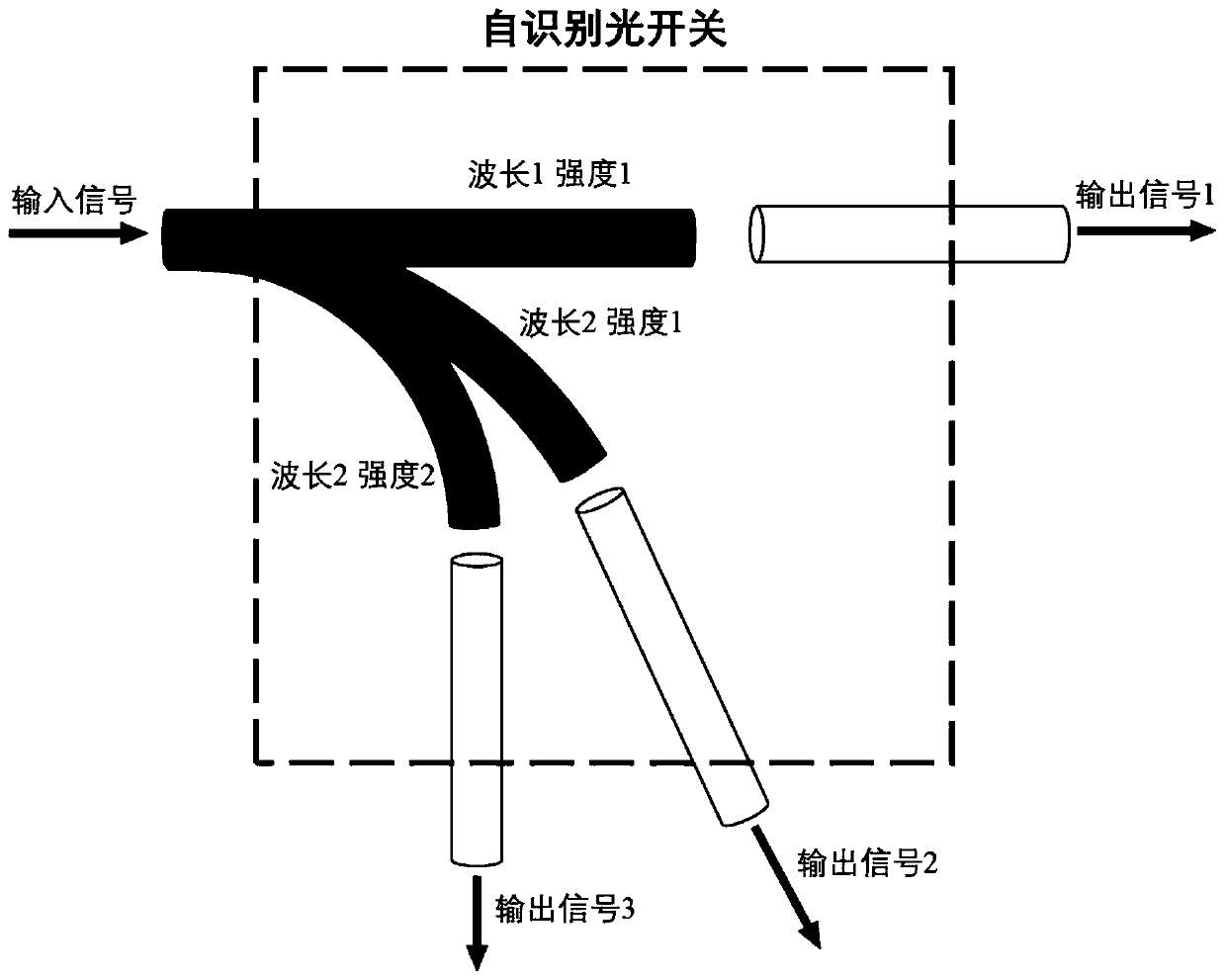

[0044] 1. Preparation of photoresponsive optical fiber:

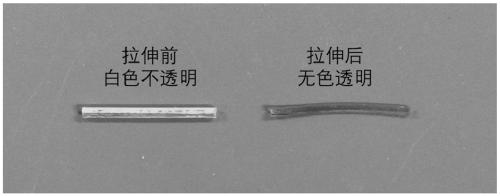

[0045] Take 300mg mesogen RM257, 72mg chain extender EDDET, 14.4mg crosslinking agent PETMP, 3mg visible light initiator Irgacure 784, mix well, add 90μL dichloromethane as a solvent, place in an oven at 70 degrees Celsius, keep warm for 5 minutes, and form A homogeneous stable solution was allowed to cool to room temperature. Add 30 μL of 2wt% DPA dichloromethane solution, vortex and mix, quickly add to a cylindrical mold with an inner diameter of 1 mm, and place at room temperature for 12 hours to form a prepolymer. Open the mold to obtain a white opaque cylinder, stretch it to a strain of 150%, and illuminate it with a wavelength of 460nm for 10 minutes (light intensity is 50mW / cm 2 ), a transparent cylindrical liquid crystal elastomer can be obtained, such as image 3 As shown, it can be used as the inner core of the optical fiber.

[0046]

[0047]

[0048] To prepare the outer cladding, take 285mg mesogen...

Embodiment 2

[0054] 1. Preparation of photoresponsive optical fiber:

[0055] Preparation of the inner core: take 300mg mesogen RM257, 72mg chain extender EDDET, 14.4mg crosslinker PETMP, 3mg UV photoinitiator HHMP, mix well, add 90μL dichloromethane as solvent, and place in an oven at 70 degrees Celsius Within 5 minutes, a homogeneous and stable solution was formed and cooled to room temperature. Add 30 μL of 2wt% DPA dichloromethane solution, vortex and mix, quickly add to a cylindrical mold with an inner diameter of 1 mm, and place at room temperature for 12 hours to form a prepolymer.

[0056] Preparation of the outer cladding: take 285mg mesogen RM257, 8.2mg photoresponsive group DR1A, 72mg chain extender EDDET, 14.4mg crosslinking agent PETMP, 3mg ultraviolet photoinitiator HHMP (photoresponsive group DR1A accounts for RM257 and 5% of the total molar weight of DR1A, and ensure that the cross-linking density of the outer cladding and the inner core is the same), after mixing evenly, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com