Shutter type MEMS large-rotation-corner adjustable blazed grating light modulator and array thereof

A louver-type, blazed grating technology, applied in the field of MEMS optical modulators, can solve the problems of failure, tuning frequency (low switching speed, small grating bar rotation angle, etc.), achieve large deflection angle, good controllability, and spectral range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below.

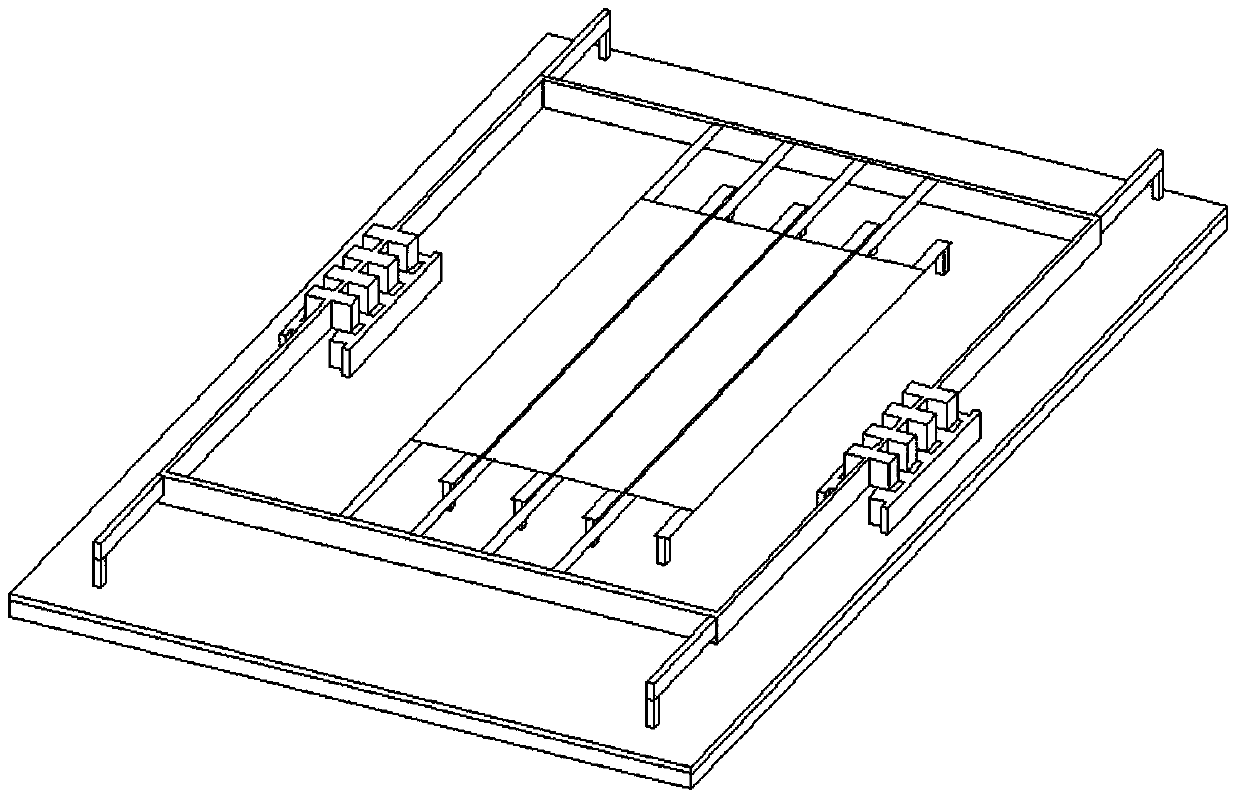

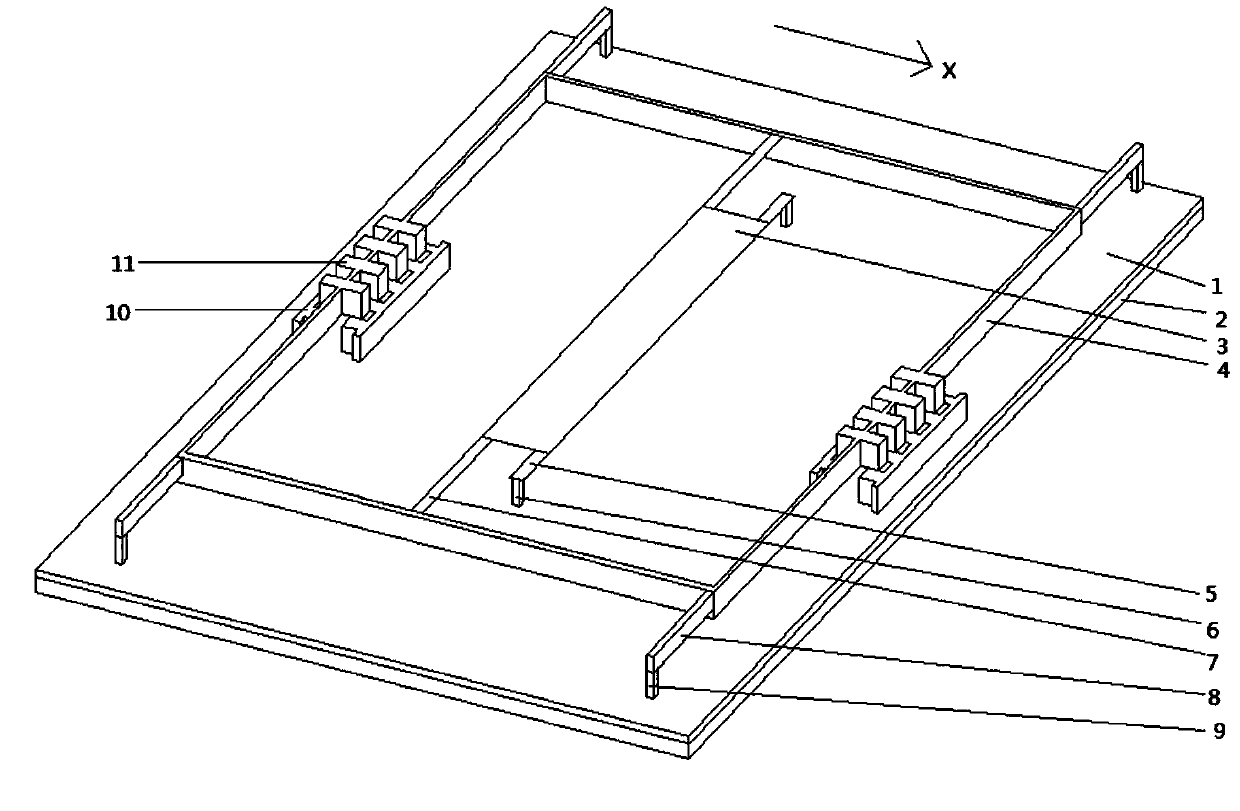

[0025] see figure 1 In this embodiment, the silicon substrate 1 of the louver type MEMS large rotation angle adjustable blazed grating optical modulator and the insulating layer 2 arranged on the silicon substrate 1, the grating mirror surface 3 is supported on the insulating layer by an elastic cantilever beam and a movable frame 4. Above the layer 2, one side of the grating is fixed on the substrate surface through the support beam 5 and two pillars 6, and the other side is connected with the movable frame 4 through the deformation beam 7. The movable frame 4 is fixed on the surface of the substrate 1 by flexible support beams 8 and pillars 9 . The fixed teeth 10 and the movable teeth 11 form a comb drive, and there are two groups. The fixed teeth 10 are fixed on the surface of the substrate 1 , and the movable teeth 11 and the movable frame 4 are integrated. The fixed teeth 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com