Table type tenoning device for woodworking

A tenoning machine and desktop technology, applied in wood processing appliances, mortising machines, slotting machines, etc., can solve the problems of complicated operation, inconvenient movement and control, and high cost, and achieve a good sense of control, flexible control, advance and retreat. free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is further described.

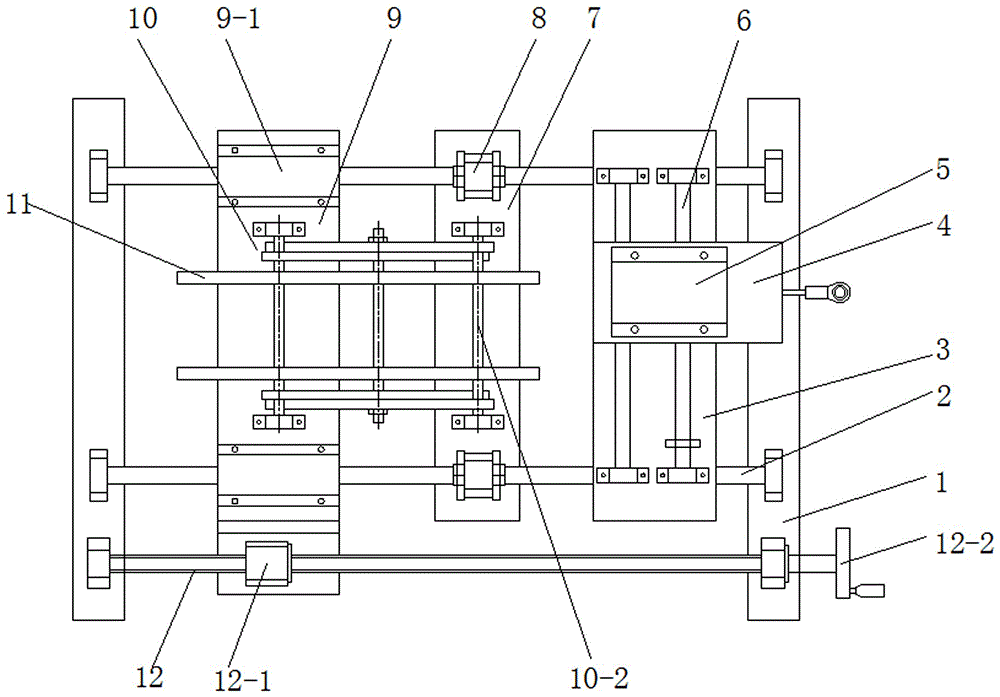

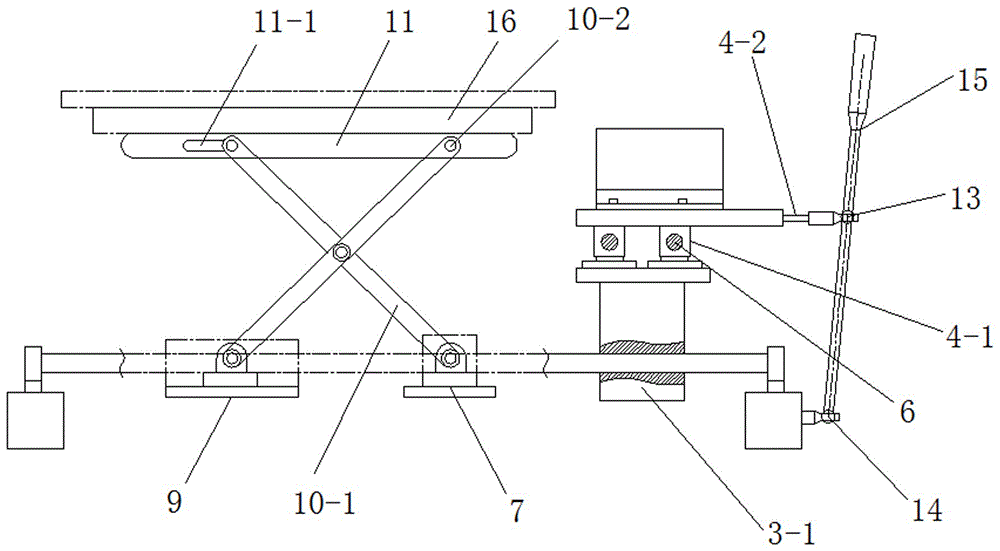

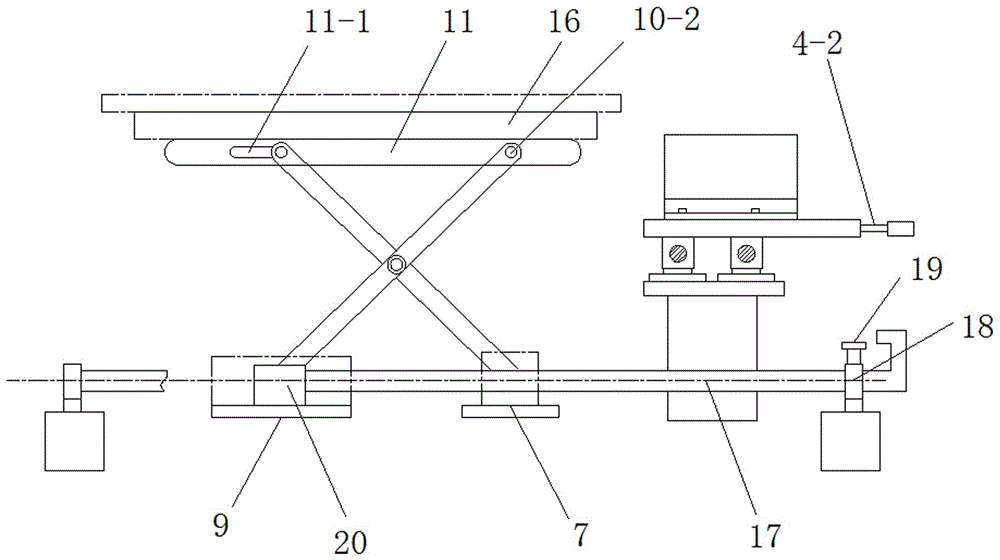

[0024] Such as Figure 1-Figure 3 The table-type tenoner for woodworking shown includes a base 1, on which there is a track 2, and on the track 2 are sequentially provided with slides I3, II7 and III9, and the slide I3 is slidably connected to the track 2 The sliding seat II7 and the sliding seat III9 are both slidingly connected to the track 2, or one of the sliding seat II7 and the sliding seat III9 is fixed on the track 2, and the other is slidingly connected to the track 2;

[0025] The sliding seat I3 is provided with an adjusting seat track 6 intersecting with the sliding direction of the track 2, and an adjusting seat 4 is slidably installed on the adjusting seat track 6;

[0026] The sliding seat II7 and the sliding seat III9 are equipped with a folding lifting mechanism 10, and the upper end of the folding lifting mechanism 10 is equipped with a horizontal joist 11;

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com