Automatic feeding and discharging heating piece pressing machine

A technology of automatic loading and unloading and heating tablets, which is applied in the field of punching machines and automatic loading and unloading heating tablet presses, which can solve the problems of time-consuming, operator burden, and limited production efficiency, so as to reduce the burden on workers and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

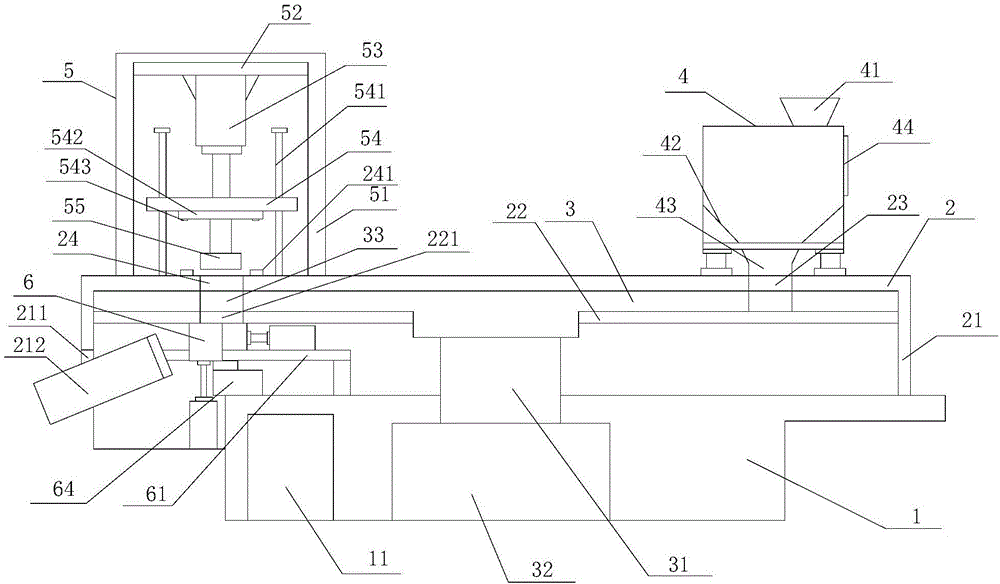

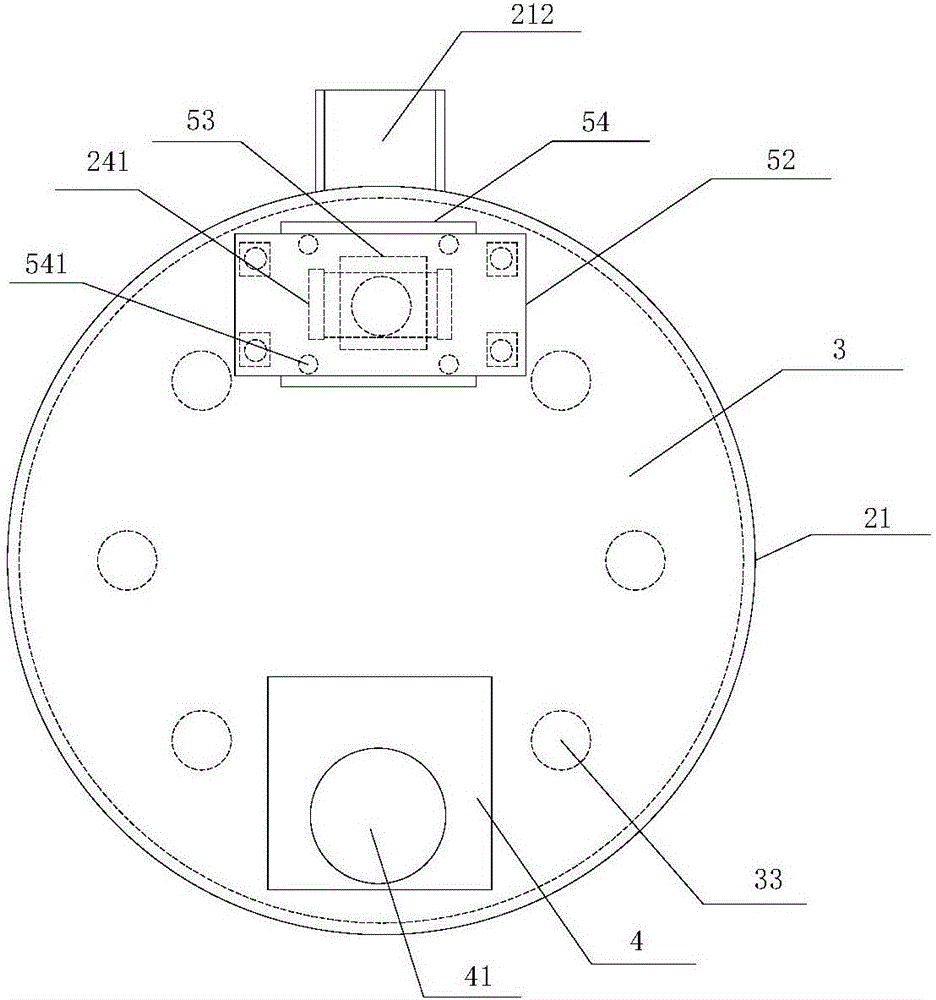

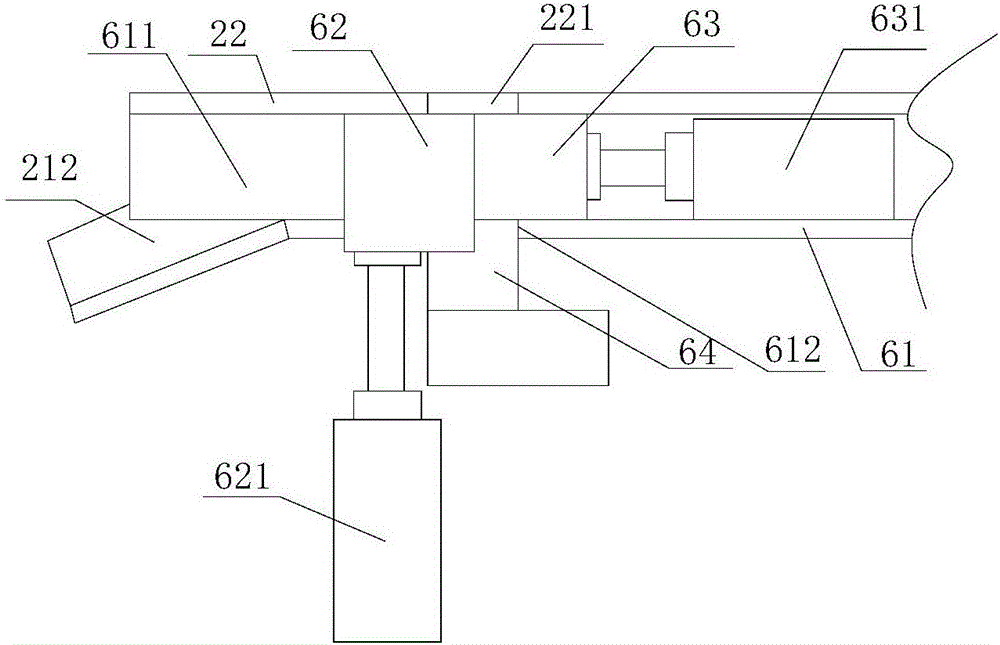

[0021] refer to Figure 1 to Figure 4 , the present invention is an automatic loading and unloading heating sheet tablet press, comprising a frame 1, a fixed installation frame 2, a feeding turntable 3, a storage box 4, a stamping device 5 and a feeding device 6, the frame 1 is A fixed installation frame 2 is provided, and a feed inlet 23 and a stamping groove 24 are provided on the fixed installation frame 2. The feed inlet 23 is matched with the storage box 4, and a support plate is arranged inside the fixed installation frame 2. 22. A feeding turntable 3 is provided between the fixed installation frame 2 and the support plate 22. The feeding turntable 3 is connected to the power box 32 through a rotating shaft 31. A control system 11 is provided on the frame 1. The The control system 11 cooperates with the power box 32, and several storage tanks 33 are provided on the feeding turntable 3, and the storage tanks 33 are matched with the feeding port 23, and a blanking tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com