Plastic sheeter

A technology of tablet press and plastic sheet, applied in the field of plastic processing equipment, can solve the problems such as difficulty in stabilizing the order quantity and product life cycle, high requirements on the flatness and parallelism of the movable and fixed template, affecting the quality stability, etc. The effect of saving equipment input cost and subsequent operation, broad application prospects and commercial value, saving working space and installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and preferred embodiments.

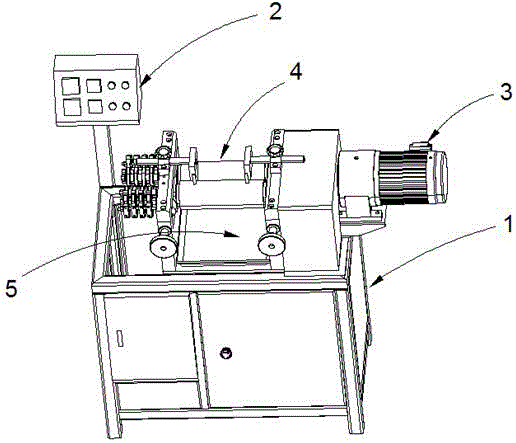

[0021] figure 1 with figure 2 It is a schematic diagram of a preferred embodiment of a plastic tablet press provided by the present invention. Such as figure 1 As shown, the plastic tablet press machine includes a frame body 1 , a control panel 2 arranged on the frame body 1 , a driving motor 3 and a tablet pressing device 4 , wherein the control panel 2 and the driving motor 3 are electrically connected.

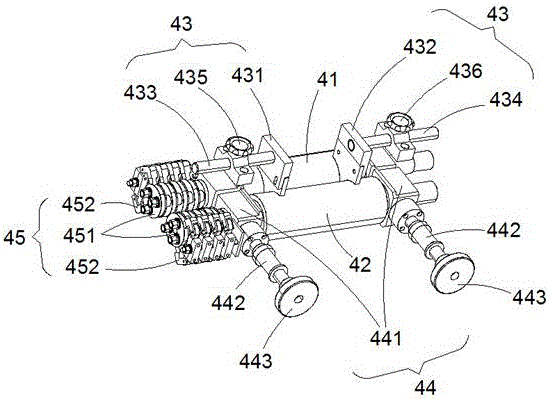

[0022] Such as figure 2 As shown, the tablet pressing device 4 includes a main pressing roller 41, an auxiliary pressing roller 42, a plastic sheet width adjusting assembly 43, a plastic sheet thickness adjusting assembly 44 and a stop assembly 45, wherein the main pressing roller 41 and the auxiliary pressing roller 42 have surfaces Quenching treatment is adopted, and the inner cores of the main pressure roller 41 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com