Mold and production process of gas-assisted electroplated product

A product and mold technology, applied in the production of gas-assisted electroplating products, can solve problems such as shrinkage, air marks, hot-melt process, etc., and achieve the effect of simplifying the hot-melt process, facilitating pressure maintenance, and simple hot-melt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

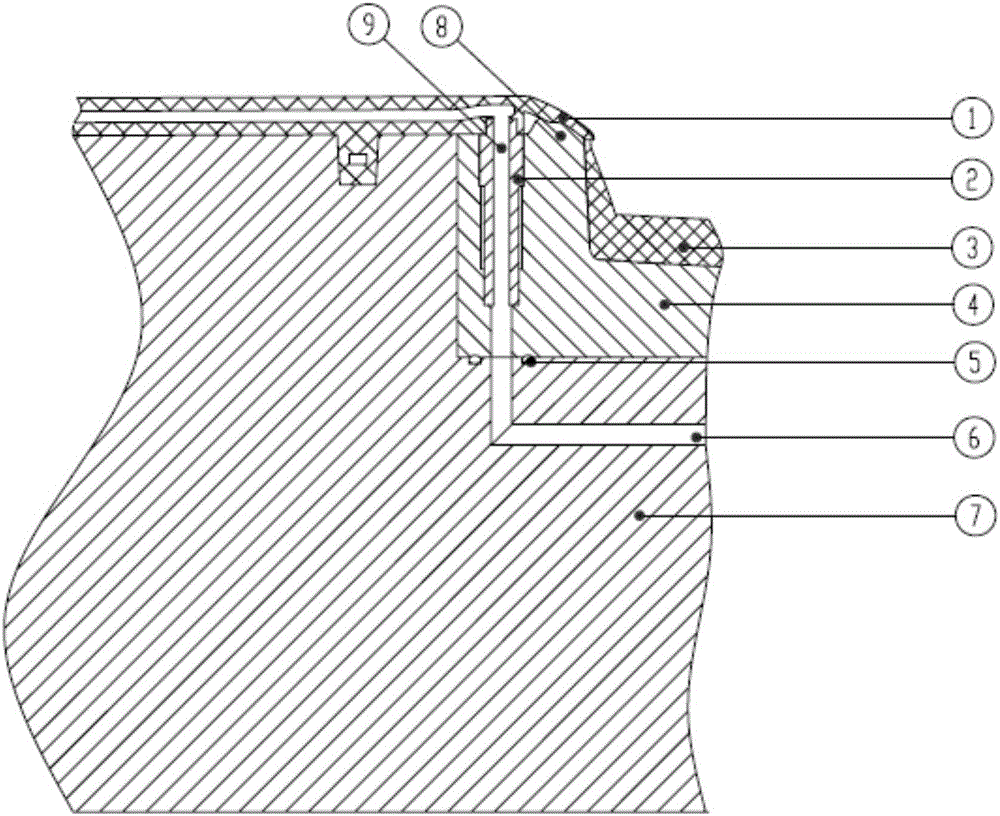

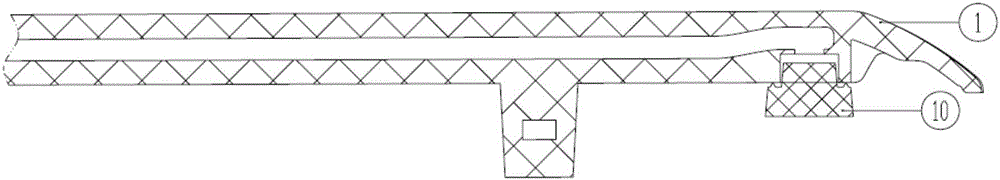

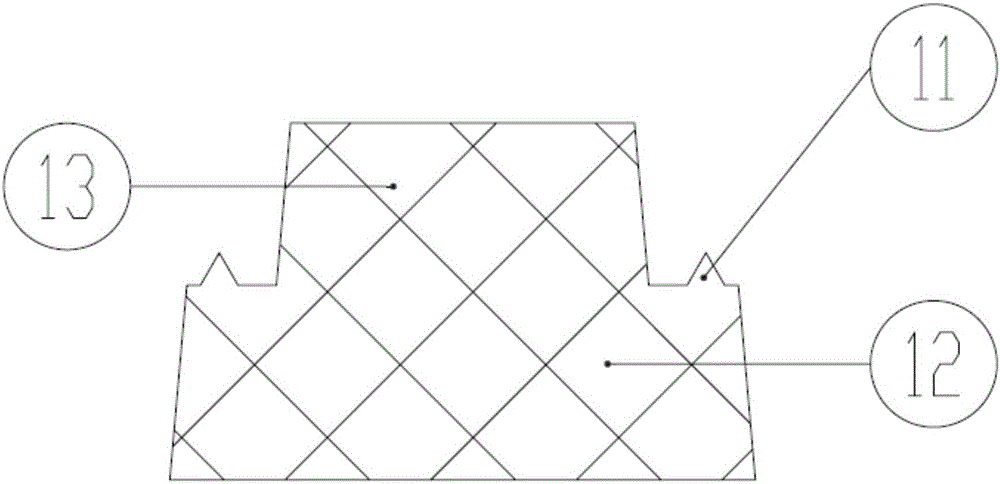

[0026] A production process of a gas-assisted electroplating product, the specific operation steps are as follows:

[0027] (a) Gas-assisted injection molding is divided into injection molding period, inflation period, gas pressure holding period and demoulding period. First, in the injection molding period, a quantitative amount of molten plastic is injected into the mold cavity through the gate 3;

[0028] (b) Then in the inflation period, in the middle and later stages of the injection molding period, inject high-pressure inert gas from the gas path 6 at different times, and the maximum pressure of the gas injection must be greater than the injection pressure;

[0029] (c) Next, during the gas pressure holding period, after the product 1 is filled with gas, the gas continues to act on the hollow part of the product 1;

[0030] (d) Then, in the demoulding period, with the completion of the cooling cycle, the gas pressure of the mold is reduced to atmospheric pressure, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com