Tread and belt ply combined type non-pneumatic tire

A non-pneumatic tire and belt layer technology, applied to the reinforcement layer of pneumatic tires, non-pneumatic tires, tire parts, etc., can solve the problem of ride comfort, rolling resistance and high-speed performance that are difficult to achieve load bearing and shock absorption, Rolling resistance and high-speed performance are not as good as those of pneumatic tires, and the compression deformation of the tread is large, so as to achieve the effect of reducing material cost, improving high-speed performance, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be described below in conjunction with specific embodiments.

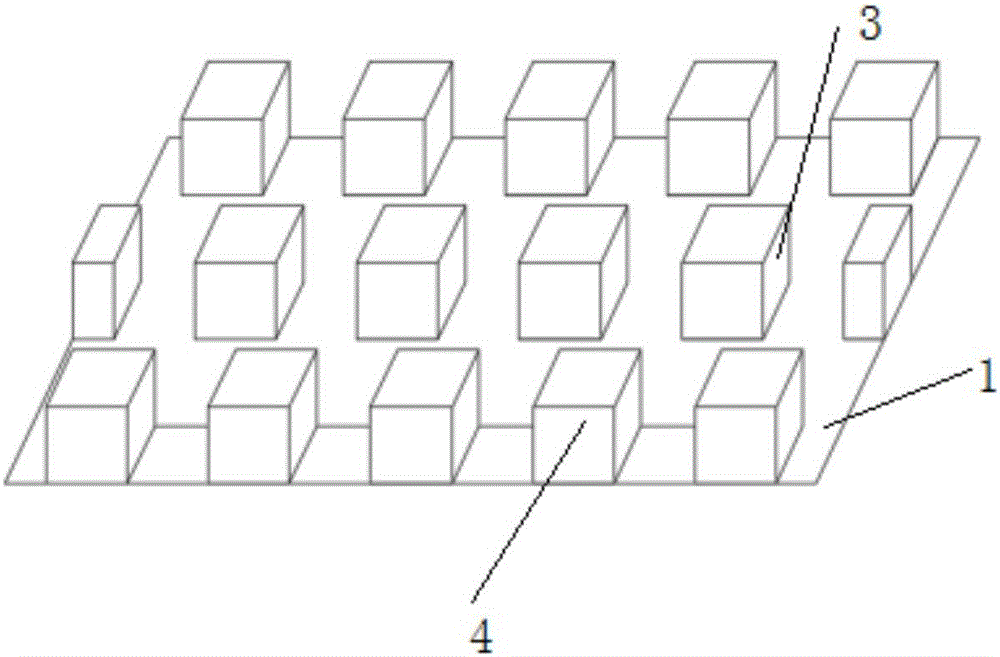

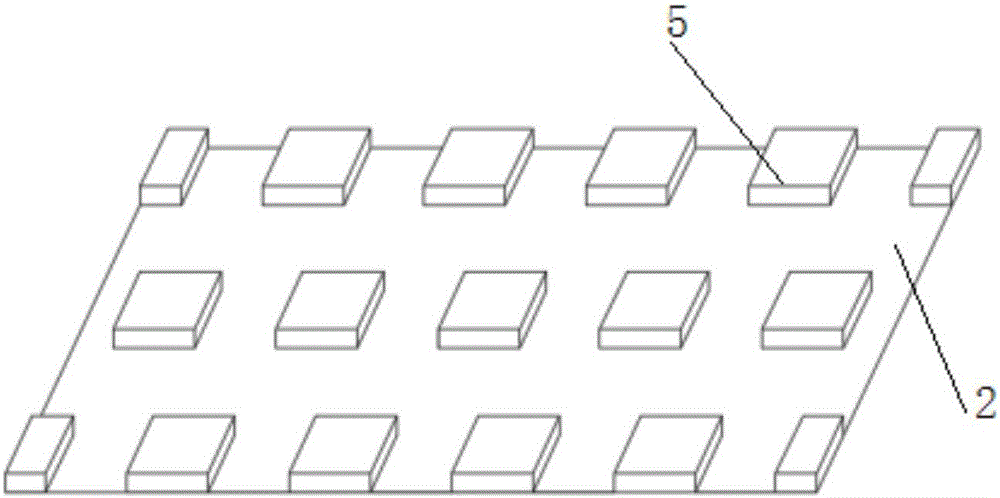

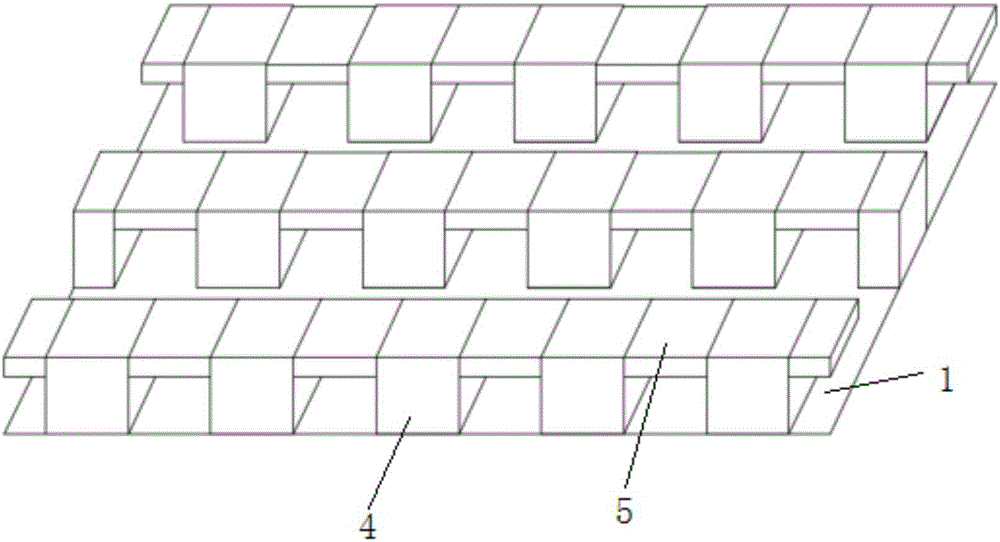

[0032] like Figure 1-Figure 8 As shown, the non-pneumatic tire with a tread combined with a belt layer includes a rim 1, a tread component and a support body 3, and the support body 3 is distributed around the outer peripheral wall of the rim 1, and the The support body 3 is composed of several rows of block pieces 4, the block pieces 4 are hollow structures made of plastic material, and the hollow structure made of plastic material has high rigidity and large load-bearing capacity, which can reduce the weight of the tire. To overcome the hysteresis loss of the rubber elastic body and reduce the rolling resistance, a distance is kept between two adjacent rows of block parts 4 in the plurality of rows of block parts 4, and two adjacent rows of block parts 4 in each row There is also a distance between the blocks 4. The tread components include the tread 2 and the ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com