Self-adaptive hydraulic sidesway balance system

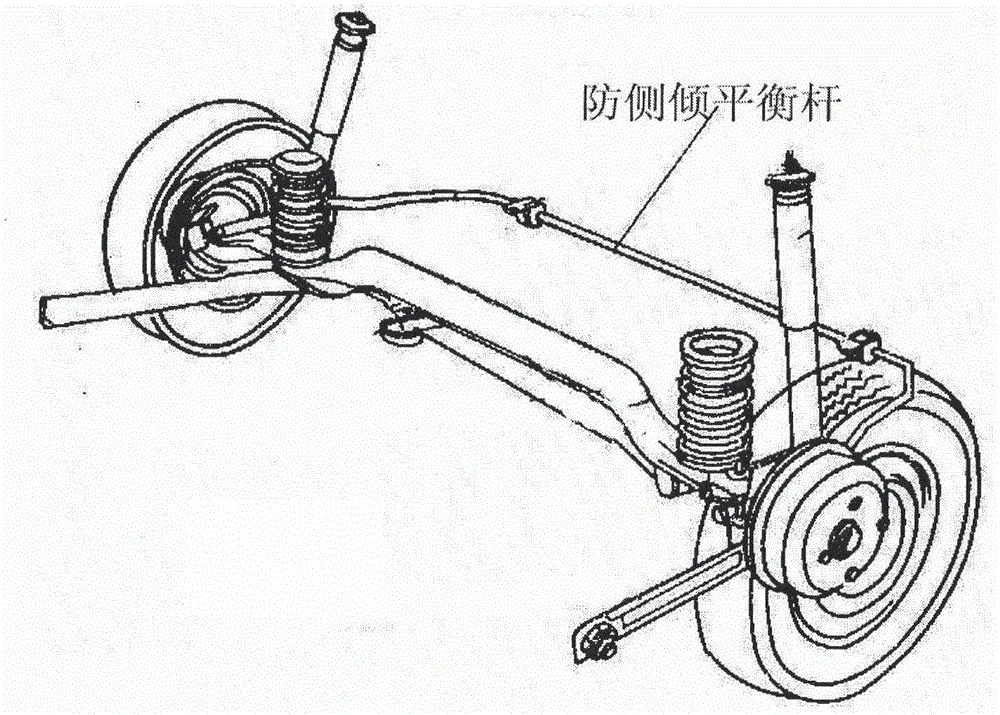

A balanced system and self-adaptive technology, applied in the interconnection system, suspension, transportation and packaging, etc., can solve the problems of difficult vehicle handling, stability, comfort and ideal safety, so as to improve the suspension performance, Save space and expand the effect of using functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

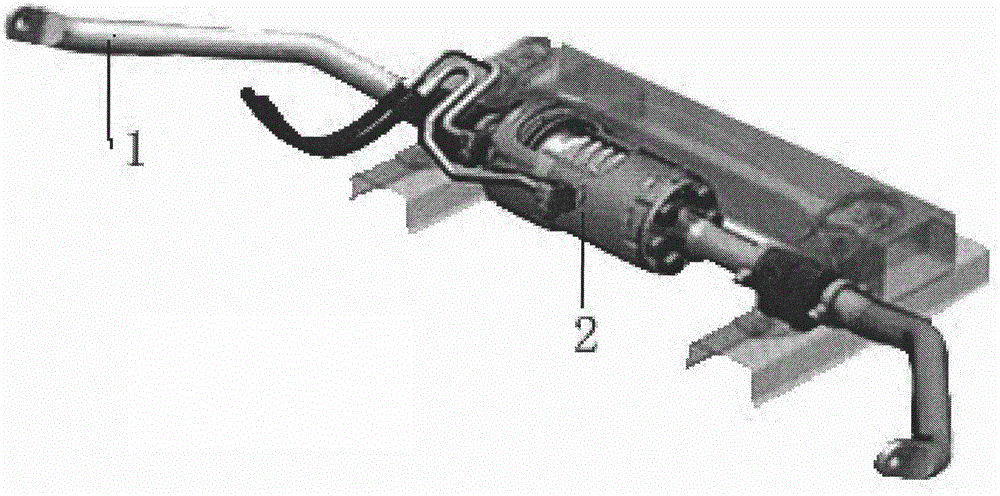

Method used

Image

Examples

Embodiment Construction

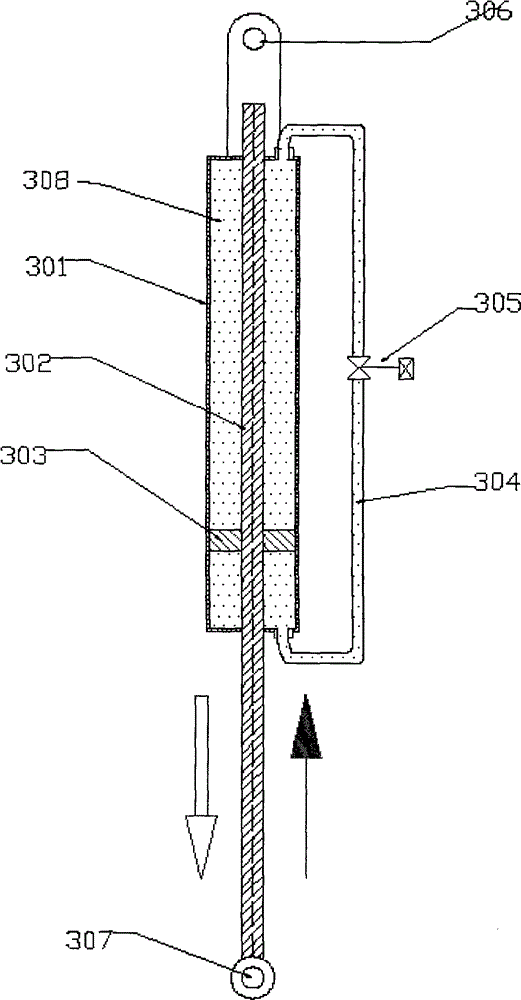

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below with reference to the accompanying drawings and examples.

[0028] Figure 4 It shows a fully hydraulic tilting force balance device including a parameter controlled axial clutch in a specific implementation of the present invention, and the traditional torsion balance bar is replaced by interconnected communication pipes. The first installation hole 306 of the centrifugal force control axial clutch is hinged to the installation point 407 of the vehicle body 406 , and the second installation hole 307 is hinged to the wheel bracket 408 . Under the control of the parameter control unit, the centrifugal force controls the axial clutch to realize the free jumping of the wheels when the vehicle is going straight, so as to enhance the comfort. Balances tilting forces when the vehicle is cornering an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com