Through battery box and vehicle with same

A battery compartment and through-type technology, which is applied in the direction of vehicle components, battery pack components, circuits, etc., can solve the problems of reduced space at the rear end of the flat floor, reduced space in the car, and small space for the flat floor, and achieves convenient and fast replacement. Ensure normal function and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further elaborated below in conjunction with the accompanying drawings.

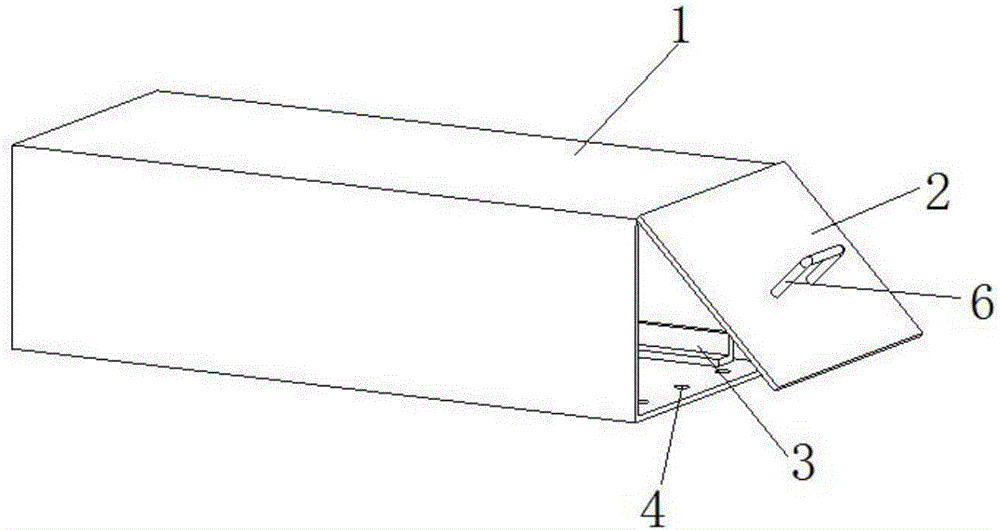

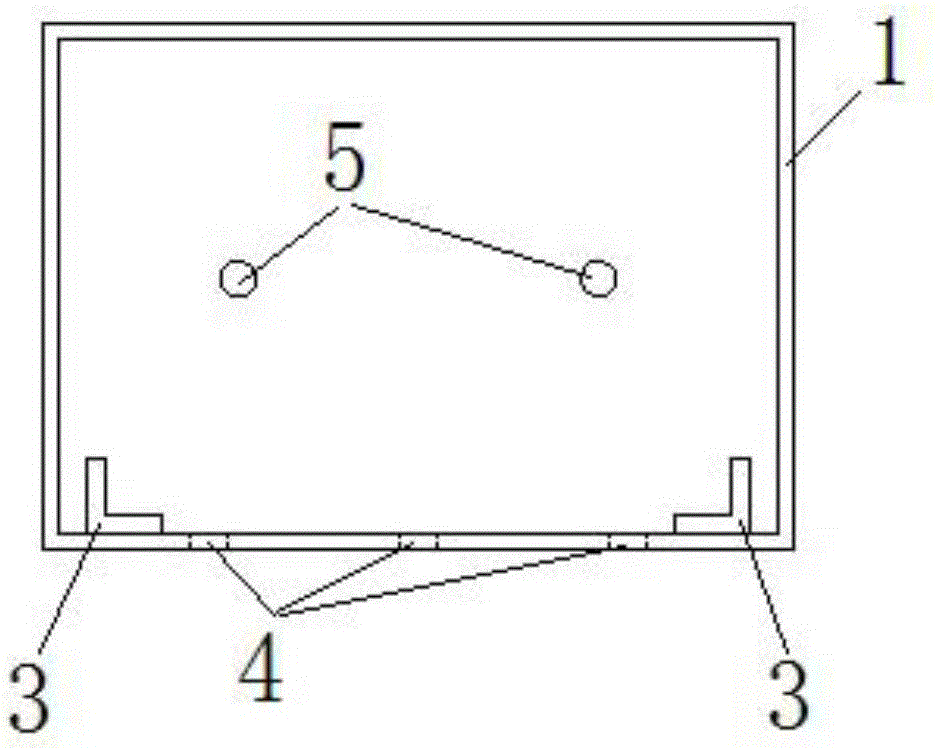

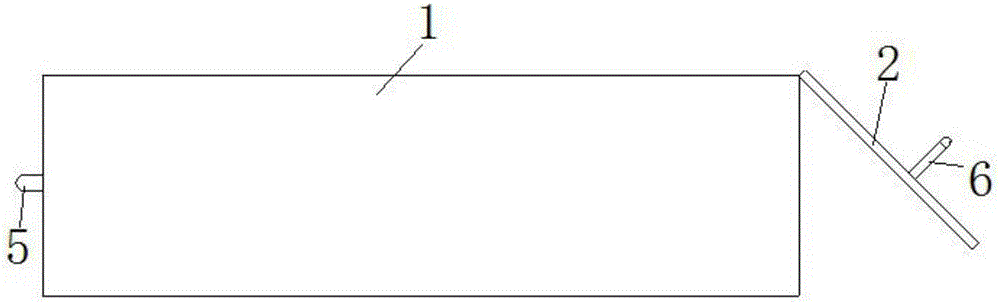

[0033] In this embodiment, a through-type battery compartment, such as the attached Figure 1-3 As shown, the warehouse body 1 is included, and the warehouse body 1 is a cuboid composed of 6 warehouse surfaces, wherein 5 warehouse surfaces are all sealed, and 1 warehouse surface is a movable warehouse door 2; the warehouse body 1 includes guide rails 3 , positioning sleeves and fastening holes; the guide rails 3 have two, and are respectively fixed on both sides of the inner bottom surface of the warehouse body 1, and the guide rails 3 are perpendicular to the movable warehouse door 2 when it is closed; the positioning sleeves are multiple and located at On the warehouse surface opposite to the movable warehouse door 2; there are multiple fastening holes located on the inner bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com