An auxiliary transfer mechanism for goods in a carriage

A transfer mechanism and technology inside the compartment, which is applied in the field of transfer devices for goods in the compartment, can solve the problems of occupying the transport space of the compartment, laborious movement and positioning, and large sliding friction, and achieve large transport space height, high structural stability, and high The effect of structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

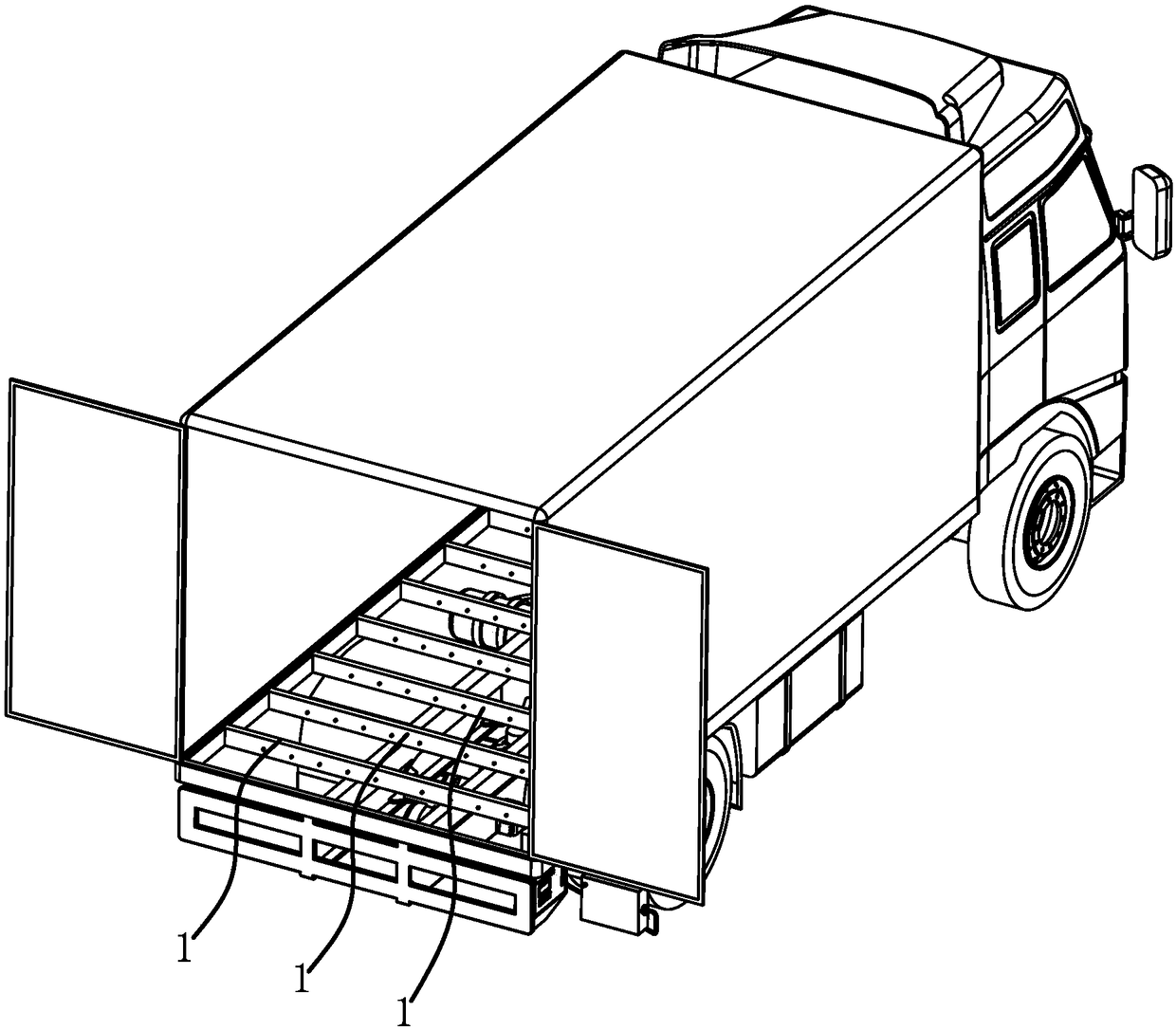

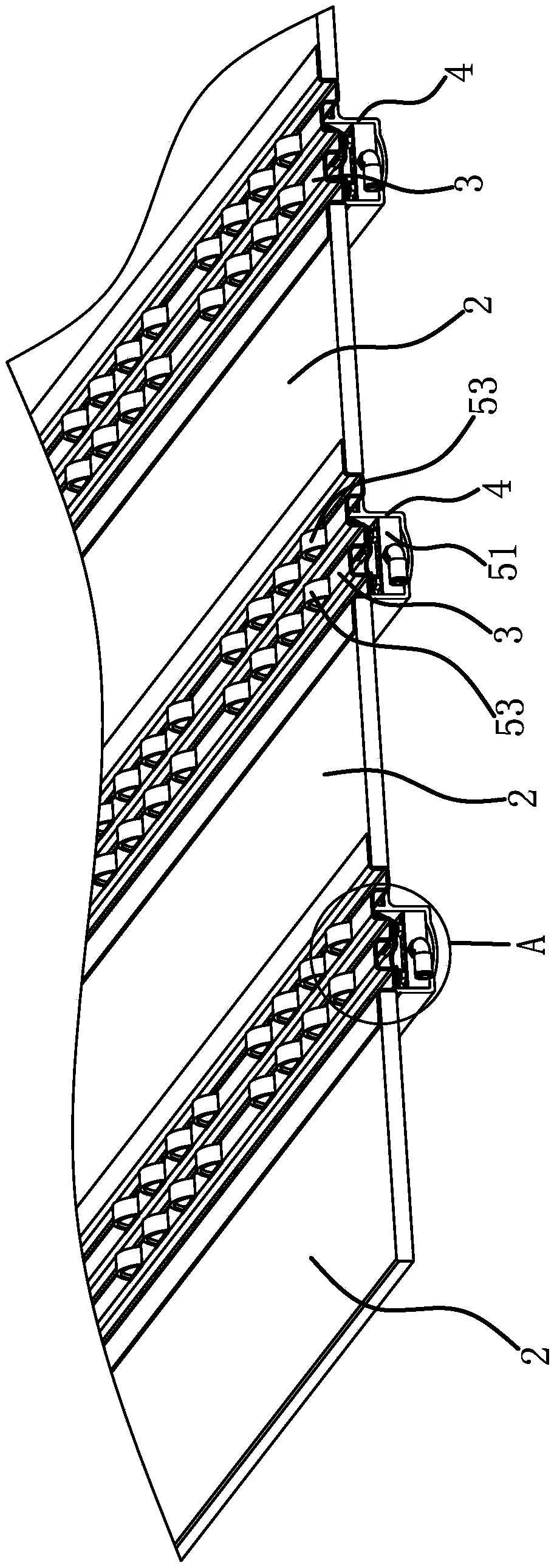

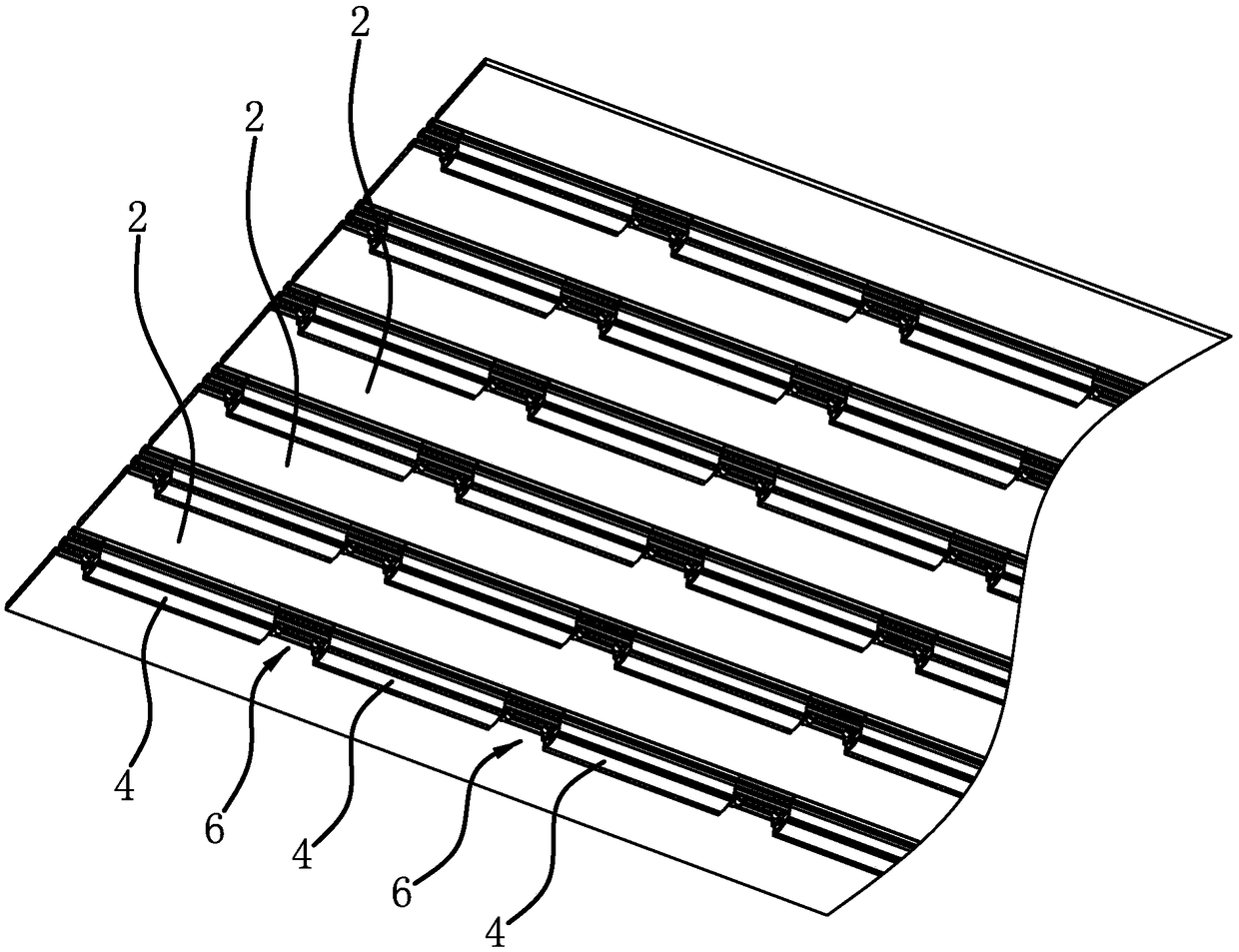

[0032] Such as figure 2 , image 3 , Figure 4As shown in the figure, an auxiliary transfer mechanism for goods in the compartment, several strip-shaped splicing plates 2 and strip-shaped support frames 4, and strip-shaped supports are fixedly connected between adjacent two splicing plates 2 along the length direction. The panel 3 and the support frame 4 are fixedly connected on the support panel 3 along the length direction, and the support frame 4 is located below the support panel 3, and an avoidance gap 6 is formed between the ends of the adjacent two support frames 4 of the same support panel 3. The splicing plate 2 is laid on the floor beam 1 of the truck compartment. At this time, the floor beam 1 of the truck is embedded in the avoidance gap 6, and the support frame 4 is embedded in the floor gap. The support frame 4 will not occupy the transportation space of the truck, so when installing After the auxiliary transfer mechanism, the truck still has a larger transpor...

Embodiment 2

[0036] The auxiliary transfer mechanism of the goods in the compartment is basically the same as that of Embodiment 1, the difference is that Figure 8 , Figure 9 As shown, the roller 53 is connected between the side plate 522 and the support plate 523 through a pin shaft 531, and the pin shaft 531 is tubular, and a strip-shaped jumper 532 is pierced inside the pin shaft 531, and the two ends of the 532 jumper are both The pin shaft 531 protrudes, and one end is fixedly connected to the side plate 522 , and the other end is fixedly connected to the support plate 523 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com