Single-rail bogie central suspension device provided with aluminum alloy connection sleeper beam

A suspension device and bogie technology, which is applied to the device for lateral relative movement between the underframe and the bogie, etc., can solve the problems of the complex structure of the height adjustment device, the bad force in the underframe area of the vehicle body, and the low sensitivity, etc. Improve the anti-rolling safety factor, simple structure, and improve the effect of stress state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

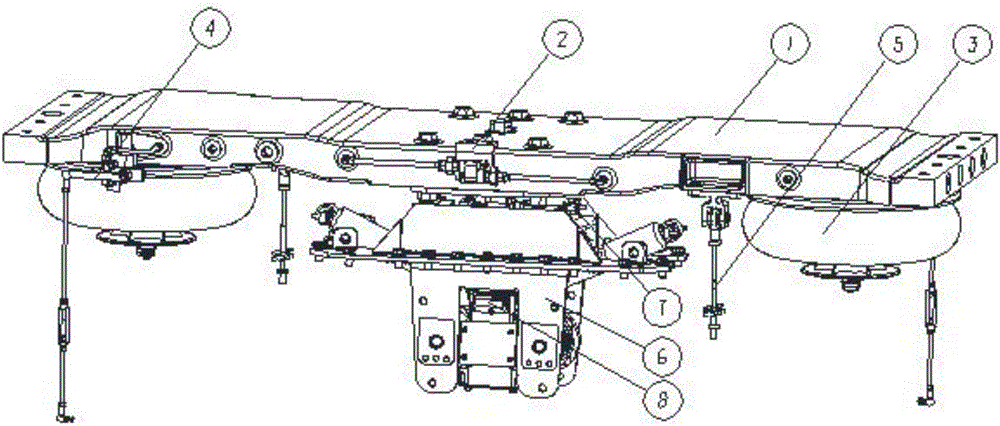

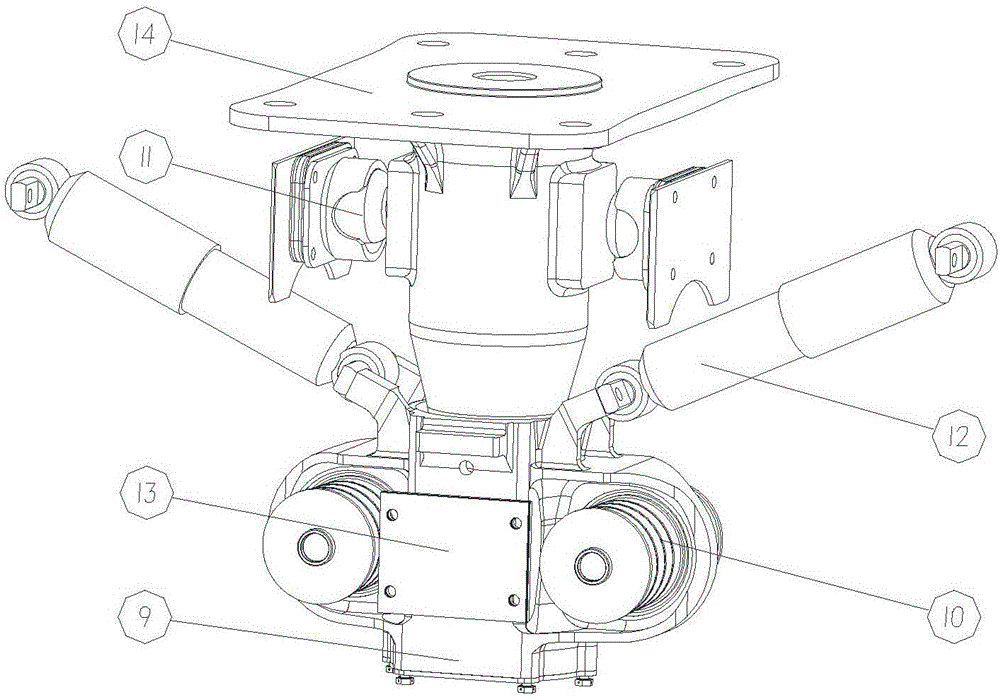

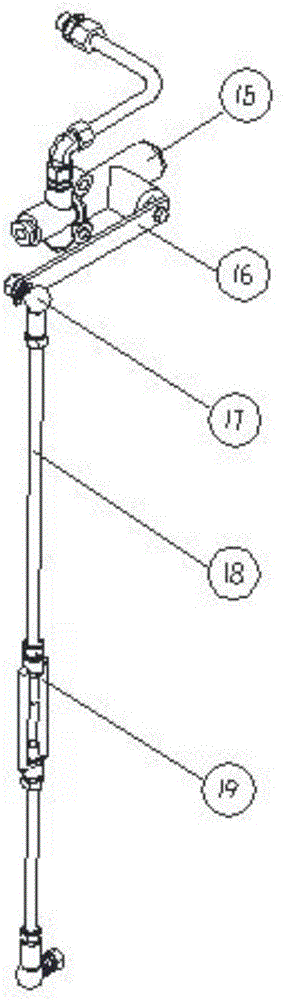

[0019] refer to figure 1 , figure 2 , in a specific embodiment of the present invention, the middle of the contact bolster 1 is connected with the center pin through a bolt group, and the two air spring seat holes on the lower surface are connected with the air spring 3; the height adjustment device consists of a height valve, a horizontal rod, two spherical hinges up and down, The upper and lower studs are composed of two studs and a turnbuckle. Among them, the upper and lower two studs rotate in opposite directions and the turnbuckle in the middle together form a two-way screw nut mechanism. One end of the height valve is fixed on the car body, and the other end is connected to the horizontal rod. , the horizontal bar is connected to the upper end of the screw nut mechanism through the upper spherical hinge, and the lower end of the screw nut mechanism is connected to the bogie frame through the lower spherical hinge; The stop is limited by the stop seat on the frame.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com