Flapping wing airship

An airship and fin technology, applied in the field of flapping airships, can solve the problems of restricting airships, low propeller efficiency, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

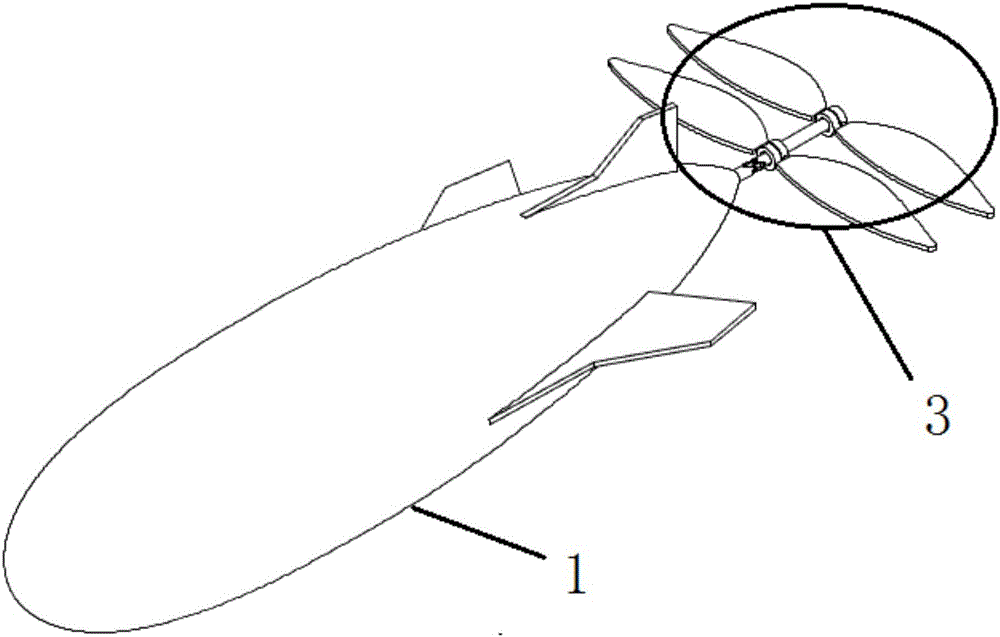

[0033] combine figure 1 , image 3 , Figure 4 and Figure 5 , a flapping-wing airship of the present invention comprises an airbag 1, an auxiliary airbag 1, a pod 2, a double flapping-wing mechanism 3, a tail boom 4, an empennage 5, a rudder and an elevator, and the outer surface of the airbag 1 is respectively provided with a pod 2, Tail boom 4, empennage 5, rudder and elevator; auxiliary airbag 1 is located in airbag 1; pod 2 is located at the bottom of airbag 1; tail boom 4 is located at the tail of airbag 1; double flapping wing mechanism 3 is arranged on tail boom 4; The flapping wing mechanism 3 comprises the flapping wing blade 6, the root shaft 7 and the universal joint 8; the root shaft 7 and the tail rod 4 are connected by the universal joint 8; the flapping wing blade 6 is provided with a ring sleeve 9; the flapping wing blade 6 passes through the ring sleeve 9 is connected with root shaft 7; empennage 5, rudder and elevator are positioned at the rear portion of...

Embodiment 2

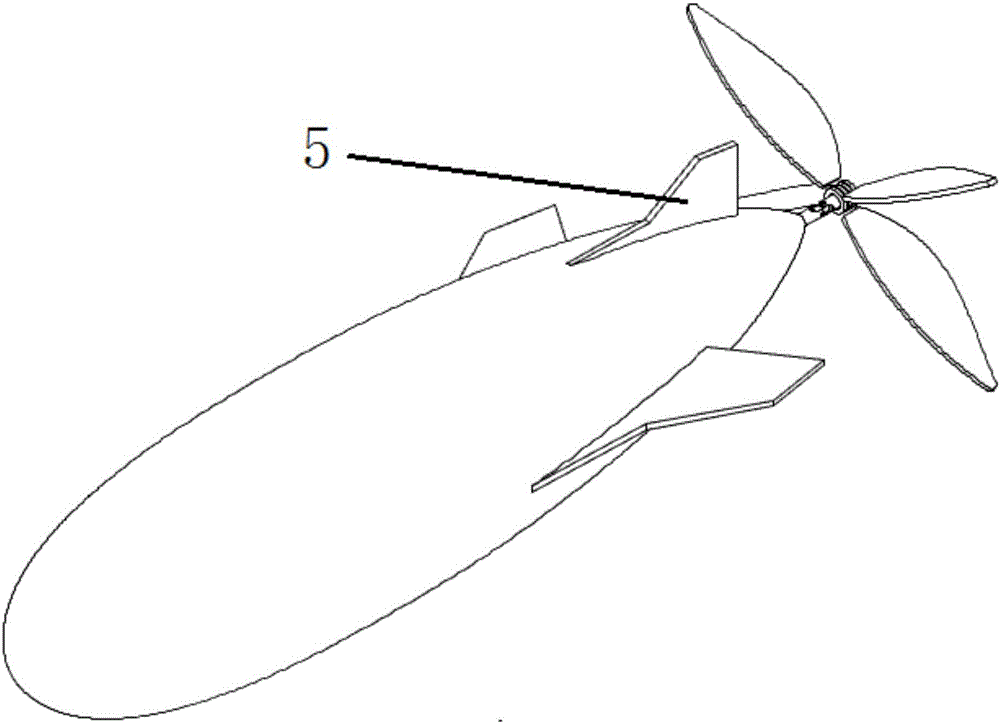

[0041] combine figure 2 , image 3 , Figure 6 and Figure 7 , a flapping-wing airship of the present invention comprises an airbag 1, an auxiliary airbag 1, a pod 2, a double flapping-wing mechanism 3, a tail boom 4, an empennage 5, a rudder and an elevator, and the outer surface of the airbag 1 is respectively provided with a pod 2, Tail boom 4, empennage 5, rudder and elevator; auxiliary airbag 1 is located in airbag 1; pod 2 is located at the bottom of airbag 1; tail boom 4 is located at the tail of airbag 1; double flapping wing mechanism 3 is arranged on tail boom 4; The flapping wing mechanism 3 comprises the flapping wing blade 6, the root shaft 7 and the universal joint 8; the root shaft 7 and the tail rod 4 are connected by the universal joint 8; the flapping wing blade 6 is provided with a ring sleeve 9; the flapping wing blade 6 passes through the ring sleeve 9 is connected with root shaft 7; empennage 5, rudder and elevator are positioned at the rear portion o...

Embodiment 3

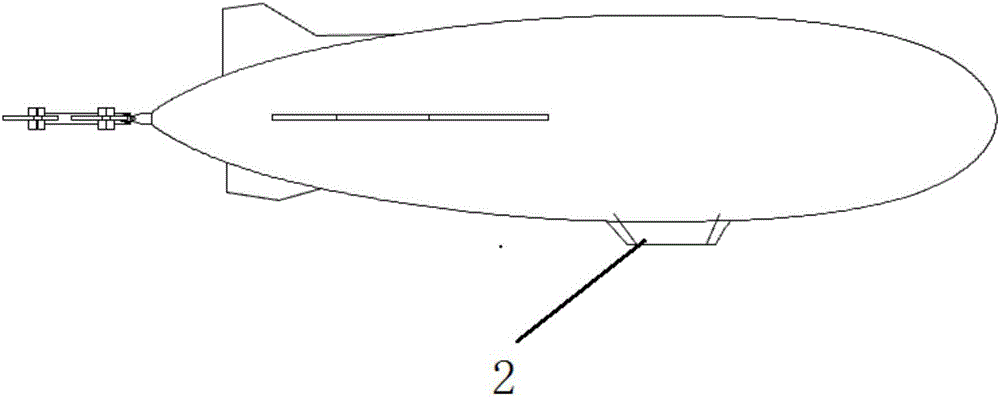

[0049] combine Figure 4 and Figure 8 , a flapping-wing airship of the present invention comprises an airbag 1, an auxiliary airbag 1, a pod 2, a double flapping-wing mechanism 3, a tail boom 4, an empennage 5, a rudder and an elevator, and the outer surface of the airbag 1 is respectively provided with a pod 2, Tail boom 4, empennage 5, rudder and elevator; auxiliary airbag 1 is located in airbag 1; pod 2 is located at the bottom of airbag 1; tail boom 4 is located at the tail of airbag 1; double flapping wing mechanism 3 is arranged on tail boom 4; The flapping wing mechanism 3 comprises the flapping wing blade 6, the root shaft 7 and the universal joint 8; the root shaft 7 and the tail rod 4 are connected by the universal joint 8; the flapping wing blade 6 is provided with a ring sleeve 9; the flapping wing blade 6 passes through the ring sleeve 9 is connected with root shaft 7; empennage 5, rudder and elevator are positioned at the rear portion of airbag 1. Double flapp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com