Asteroid microgravity surface touring mechanism

A microgravity, asteroid technology, applied in aircraft, motor vehicles, space navigation equipment, etc., can solve problems such as difficulty, drift, and detectors are easily disturbed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

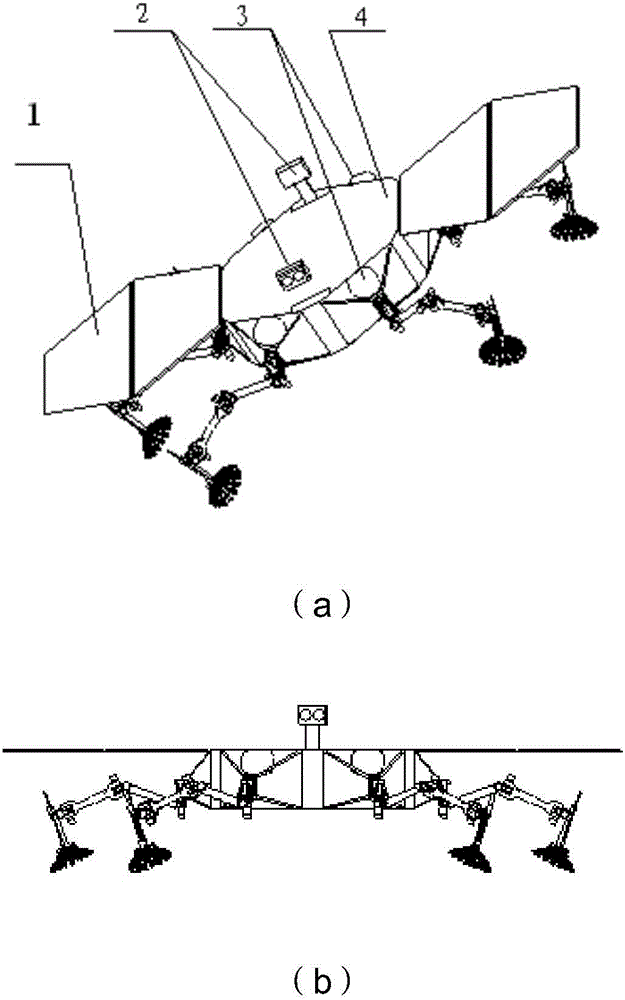

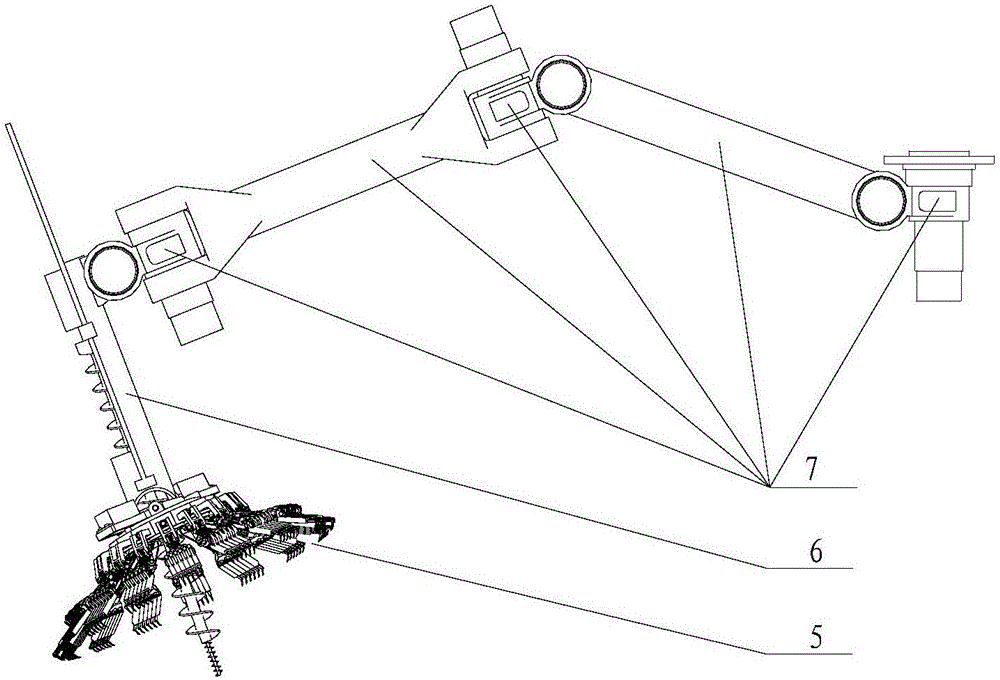

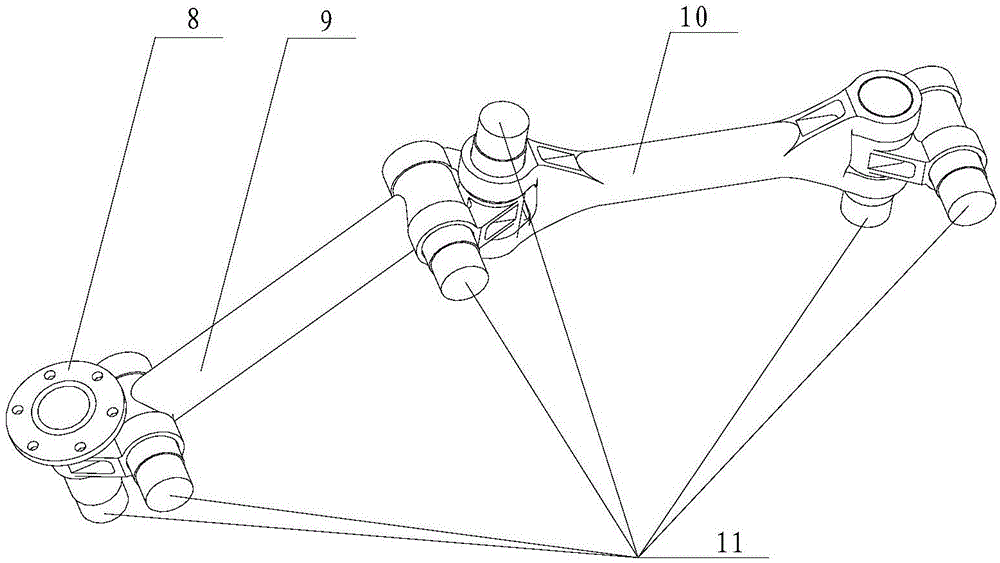

[0028] Such as figure 1 (a), figure 1 As shown in (b), an asteroid microgravity surface inspection mechanism includes: claw attachment device 5, rotary drilling device 6, crawling device 7; arranged on the main body 4 of the lander, and visual camera 2, sensor 3 and system control The instruments work together to form an asteroid microgravity surface inspection system. The crawling device adopts 6 identical 6-DOF mechanical arms, and the three spaced ones form the same group. The two groups of crawling device 7, rotary drilling device 6 and claw attachment device 5 are controlled by the system controller to perform alternate attachment-moving cycles. Realize the steering and overall translation movement of the asteroid probe. Solar panels 1 , visual cameras 2 and sensors 3 are all mounted on the main body 4 of the lander. The visual camera 2 and the sensor 3 are used to obtain environmental information such as the terrain around the lander, the distance and size of obstacle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com