Automatic stacking output mechanism

An output mechanism and coding material technology, which is applied in the field of automatic coding material output mechanism, can solve the problems of heavy workload and low work efficiency, and achieve the effects of improving work efficiency, saving packing time, and facilitating manual packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

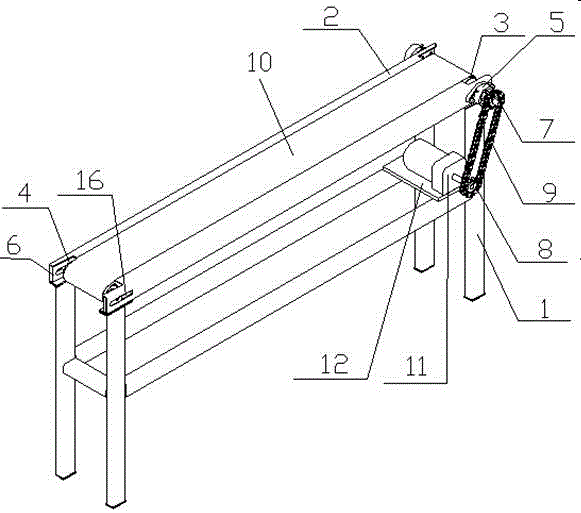

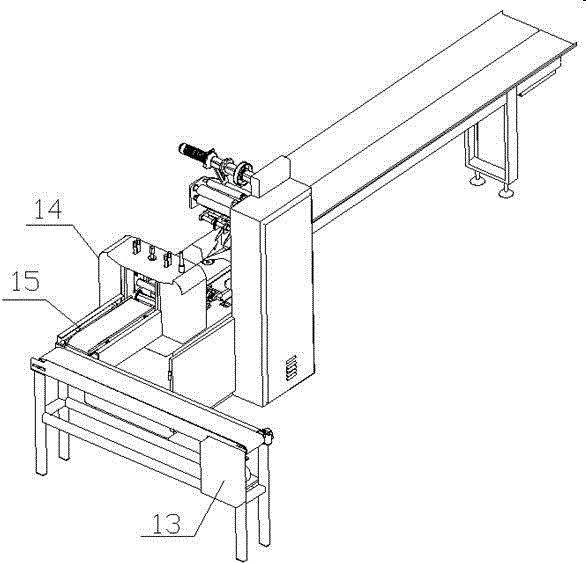

[0015] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a frame 1, side plates 2 are fixed on both sides of the upper part of the frame 1, a conveyor belt 10 is installed between the two side plates 2, bearing housings 5 are fixed on both sides of one end of the side plate 2, and the shaft of the driving roller 3 Installed on the bearing seat 5, a driven sprocket 7 is installed on one end of the shaft of the driving roller 3, and a driving sprocket 8 is installed on the output shaft of the motor 11. The driving sprocket 8 and the driven sprocket 7 are connected by a chain 9, and the motor 11 is fixed. On the motor mounting base 12, the motor mounting base 12 is fixed on the beam of the frame 1; the other end of the side plate 2 is equipped with a driven roller 4, and the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com