Powder seasoning feeding device

A seasoning and powdery technology, which is applied in the field of filling bins, can solve the problems of excessive particle size and easy agglomeration, and achieve the effect of increasing particle size, improving taste, and avoiding equipment blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

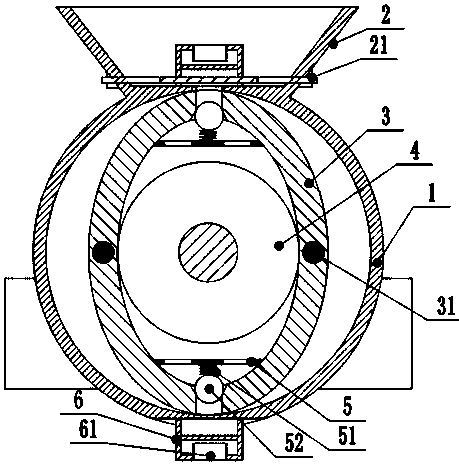

[0014] The reference signs in the accompanying drawings of the description include: accommodating chamber 1, hopper 2, screw rod 21, material box 3, rotating pin 31, pressure roller 4, mounting plate 5, spring 51, magnetic ball 52, mounting frame 6, permanent magnet 61.

[0015] The embodiment is basically as attached figure 1 Shown:

[0016] The powder seasoning feeding device consists of a frame and a conical hopper 2, the hopper 2 is installed on the upper end of the frame, and also includes an oval material box 3 and a pressing roller 4, and a circular accommodation chamber is arranged inside the frame 1. The material box 3 is rotatably connected to the frame and located in the storage room 1. The long end of the oval material box 3 is tangent to the inner wall of the circular storage room 1. The two long ends of the material box 3 are provided with feeding ports. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com