Convenient-to-mount and low-energy-consumption antiskid type belt conveyor roller

It is a technology with convenient installation and low energy consumption. It is applied in the direction of conveyor objects, transportation and packaging, and rollers. It can solve the problems of cumbersome welding and production of large iron plates, large loads driven by motors, and heavy rollers. It is not easy to drive The effect of slipping, driving load reduction, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

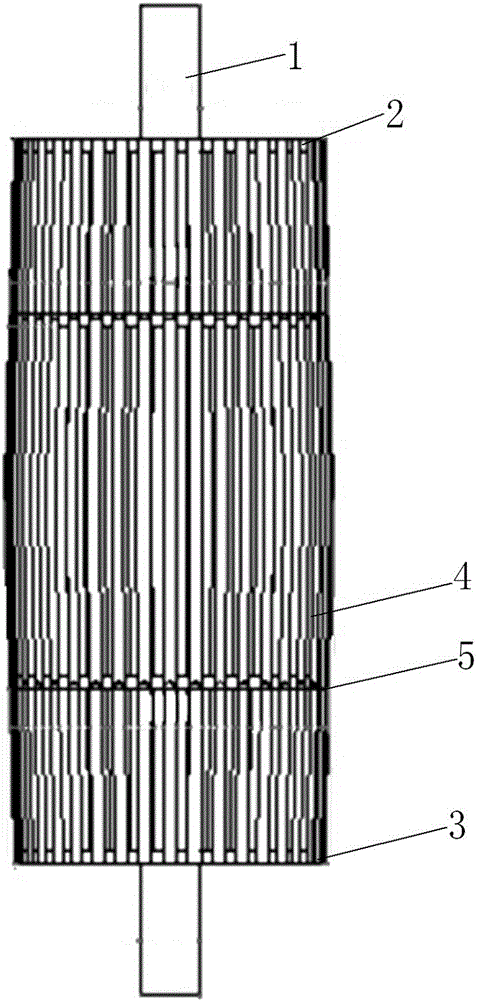

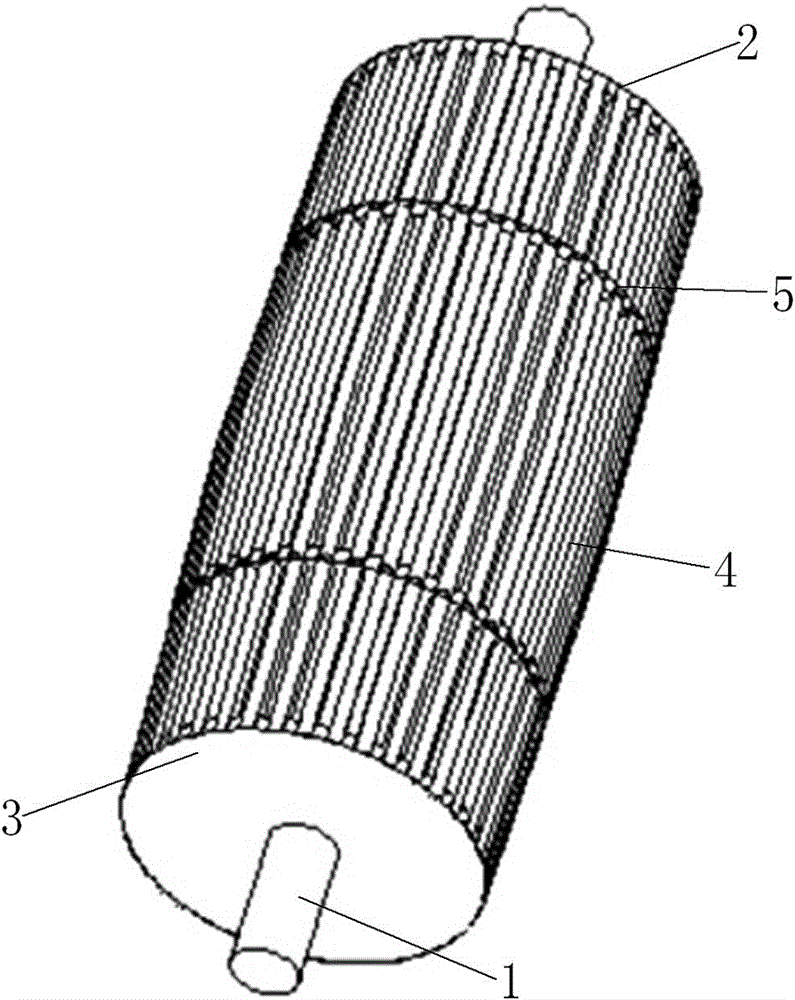

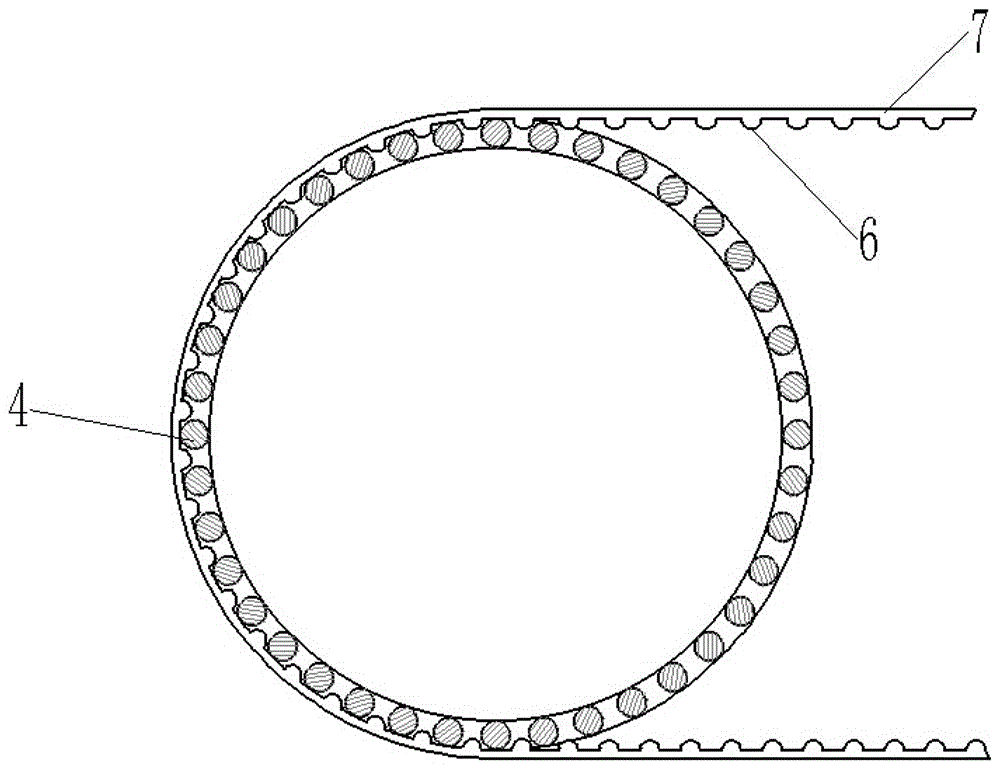

[0010] figure 1 , 2 , 3 middle: rotating shaft 1, first connecting plate 2, second connecting plate 3, connecting rod 4, hoop 5, convex body 6, conveyor belt 7.

[0011] Easy to install, low energy consumption, non-slip belt conveyor roller, the belt conveyor roller includes a rotating shaft 1, a roller assembly installed on the rotating shaft 1, and the roller assembly includes a first connecting plate 2, a second connecting plate 3, a connecting Rod 4, hoop 5, the first connecting plate 2, the second connecting plate 3 are welded and fixedly connected with the rotating shaft 1, the first connecting plate 2, the second connecting plate 3 are coaxial with the rotating shaft 1, The first connecting plate 2 and the second connecting plate 3 are circular plates, one end of the connecting rod 4 is fixedly connected with the first connecting plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap