Recovering device for stainless steel service plates

A recycling device, stainless steel technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of noise affecting appetite, slowing speed, wasting labor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

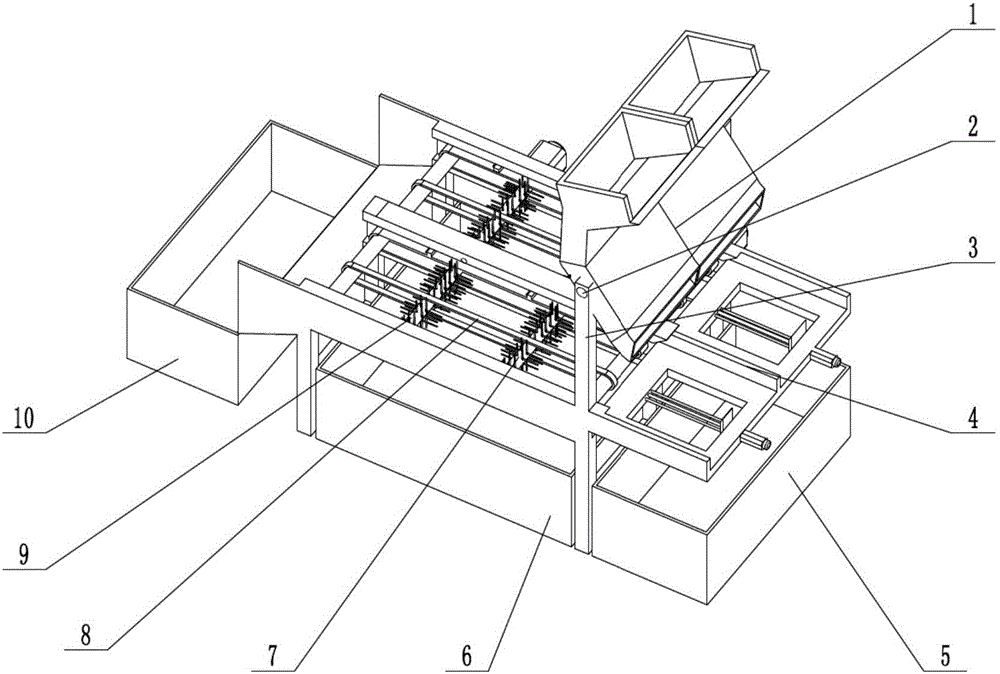

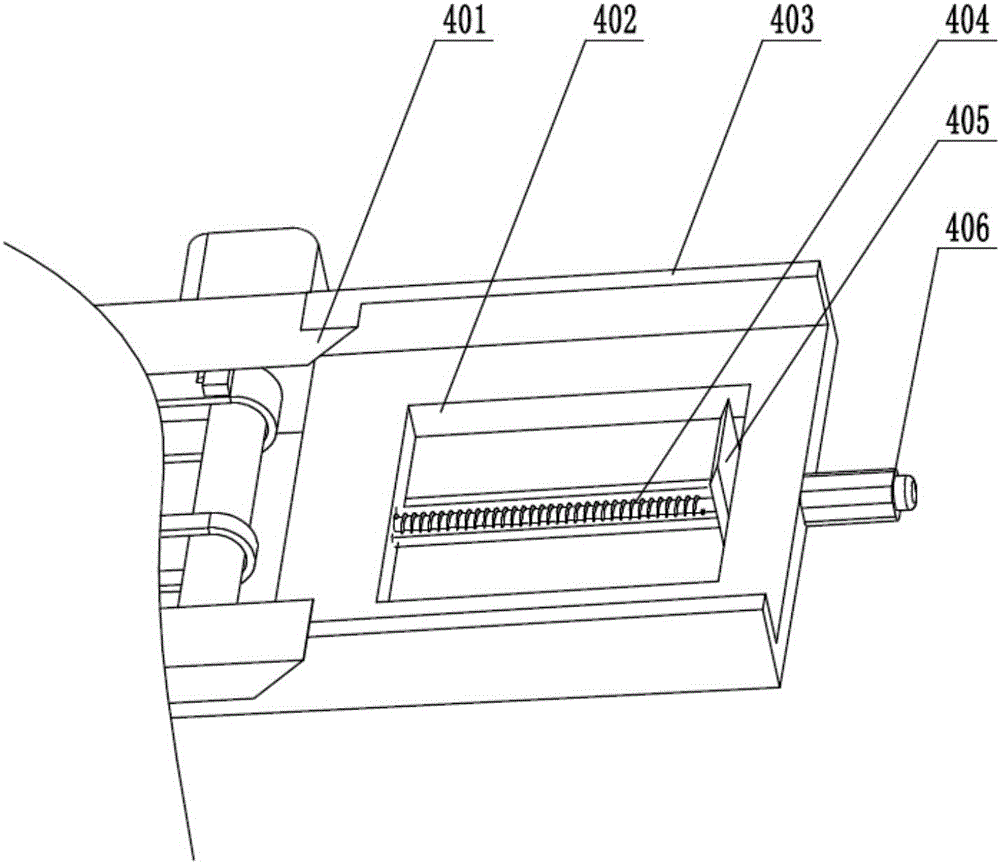

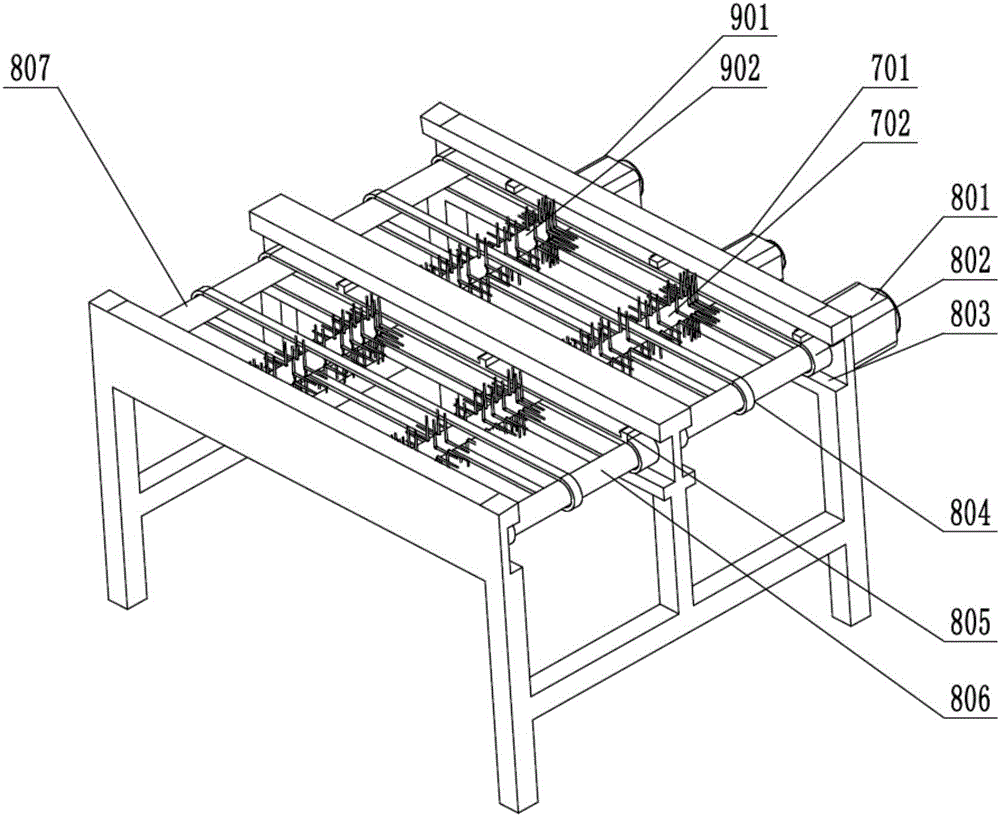

[0017] A stainless steel dinner plate recycling device is composed of a flip box 1, a fixed rotating shaft 2, a bracket 3, a push mechanism 4, a first-level food recovery box 5, a second-level food recovery box 6, a first-level sweeping roller brush 7, and a transmission mechanism 8 , secondary volume sweeping roller brush 9, and tableware recovery box 10. There are two flip boxes 1 placed in parallel, fixed on the bracket 3 by the fixed rotating shaft 2, and the bracket 3 is located between the push mechanism 4 and the transmission mechanism 8. The joint is vertically upward, and the push mechanism 4 is located in front of the transmission mechanism 8 and is horizontally parallel to the transmission mechanism 8. The push mechanism 4 is composed of a receiving tray 403, a ball screw guide rail 404, a stepping motor 406, and a front push plate. 405, separation hole 402, wedge-shaped inlet 401, the stepper motor 406 is connected with the rolling screw guide rail 404, axially pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com