Automatic loading and stacking production line

A production line, automatic technology, applied in the direction of object stacking, loading/unloading, transportation and packaging, etc., can solve the problem that automatic loading and palletizing cannot be carried out, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

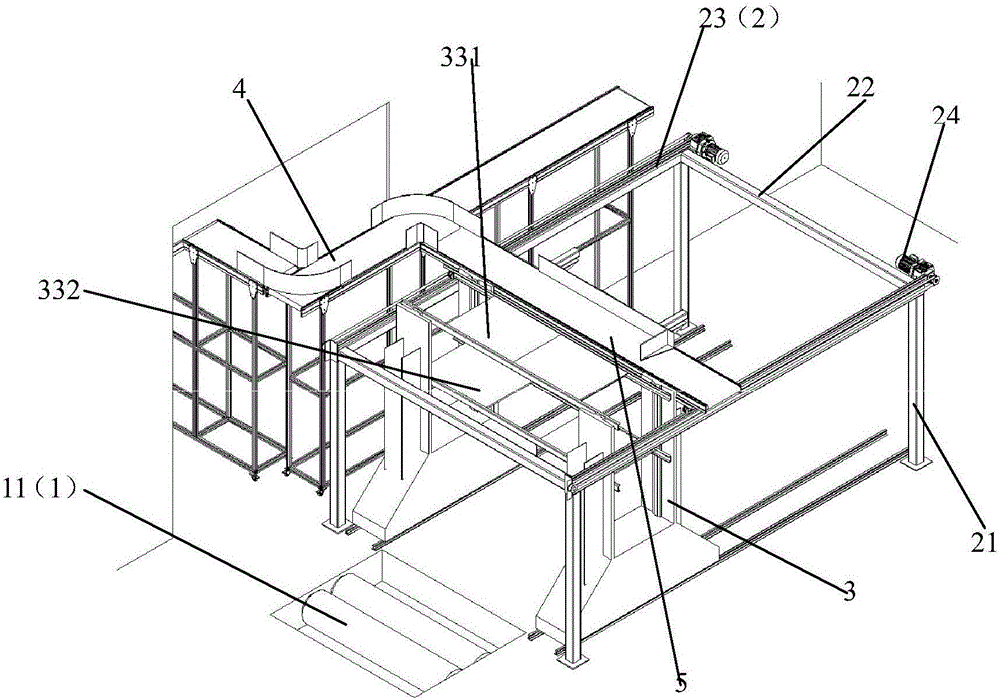

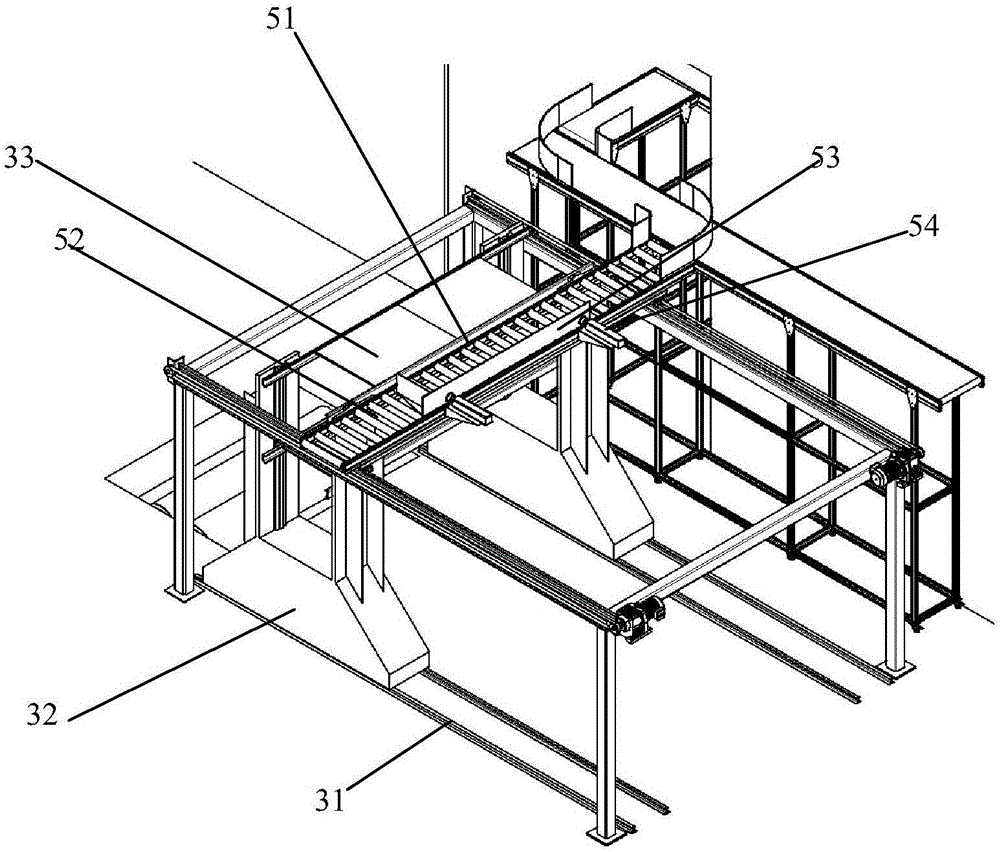

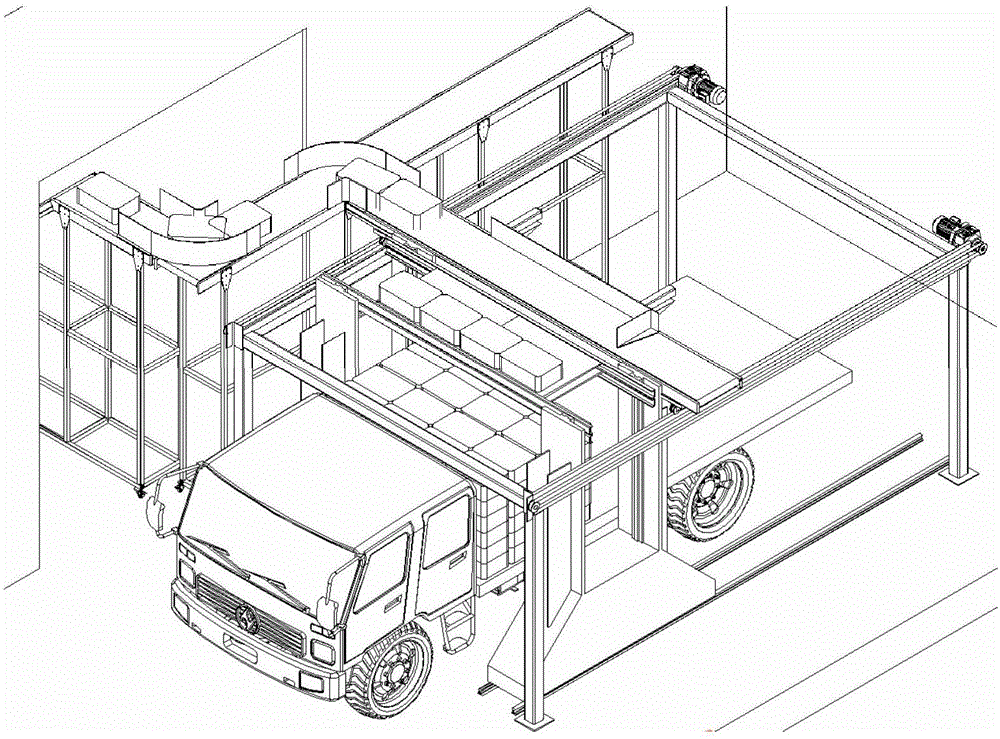

[0026] like figure 1 and 2 As shown, it is a schematic three-dimensional structure diagram of the automatic loading and palletizing production line of this embodiment.

[0027] like figure 1 and 3 As shown, an automatic loading and palletizing production line includes a vehicle positioning system 1 , an overhead gantry type automatic feeding system 2 , a column straddle type automatic stacking system 3 and an automatic feeding system 4 . It is used to automatically stack bags or boxes and various regular shaped articles into the truck compartment layer by layer and stack by stack, instead of manual operation, to realize automatic loading and stacking operations.

[0028] The vehicle positioning system is installed on the loading site, the overhead gantry type automatic feeding system is installed on both sides of the site where the trucks are positioned and parked, the column straddle type automatic stacking system is installed inside the overhead gantry type automatic feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com