Cloth intermediate conveying device capable of automatically collecting dust up and down

A conveying device and automatic dust collection technology, applied in the directions of transportation and packaging, thin material handling, winding strips, etc., can solve the problems of easy inhalation by operators and pollute the working environment, and achieve convenient follow-up cleaning, convenient replacement and maintenance. , the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

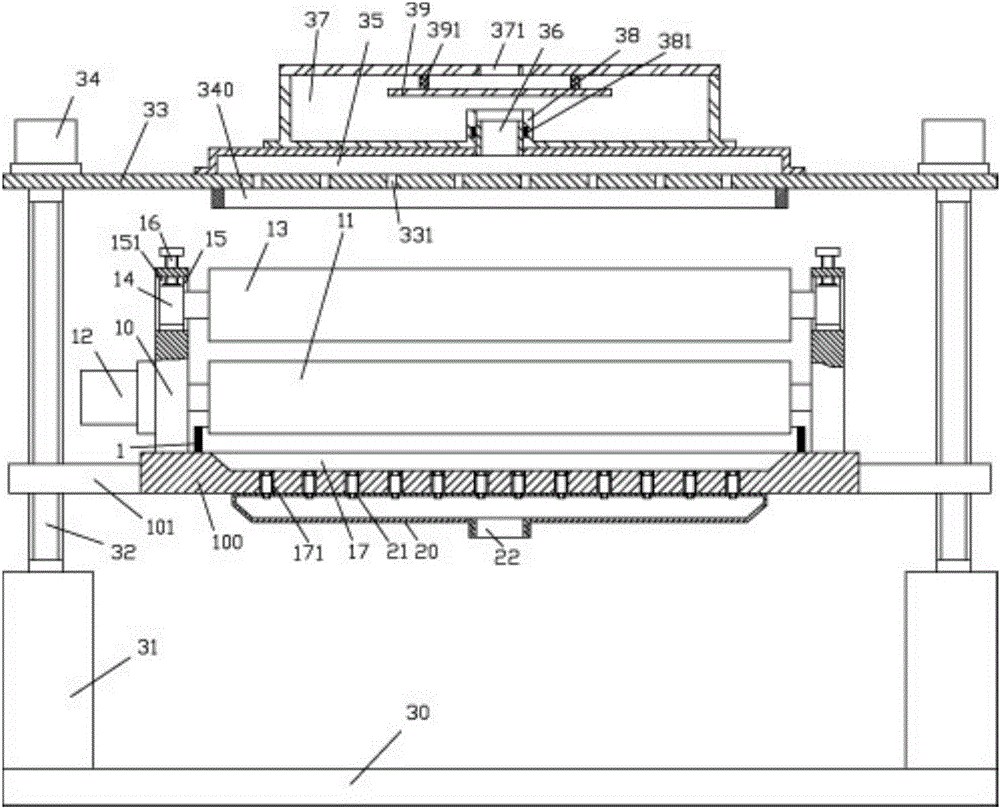

[0028] Examples, see e.g. Figure 1 to Figure 2 As shown, a cloth intermediate conveying device with automatic dust suction up and down includes a bottom plate 30, vertical connecting blocks 31 are fixed on both sides of the top surface of the bottom plate 30, and vertical connecting blocks 31 are hinged on the top surface of the vertical connecting block 31. Straight screw rod 32, the top of vertical screw rod 32 is hinged on the main top plate 33, and the top surface of main top plate 33 is fixed with lifting motor 34, and the output shaft of lifting motor 34 is a spline shaft, and the spline shaft is inserted in the corresponding vertical In the spline hole at the top of the screw rod 32, lifting connecting blocks 101 are fixed on both sides of the main bottom plate 100, and the lifting connecting blocks 101 are screwed into the corresponding vertical screw rods 32;

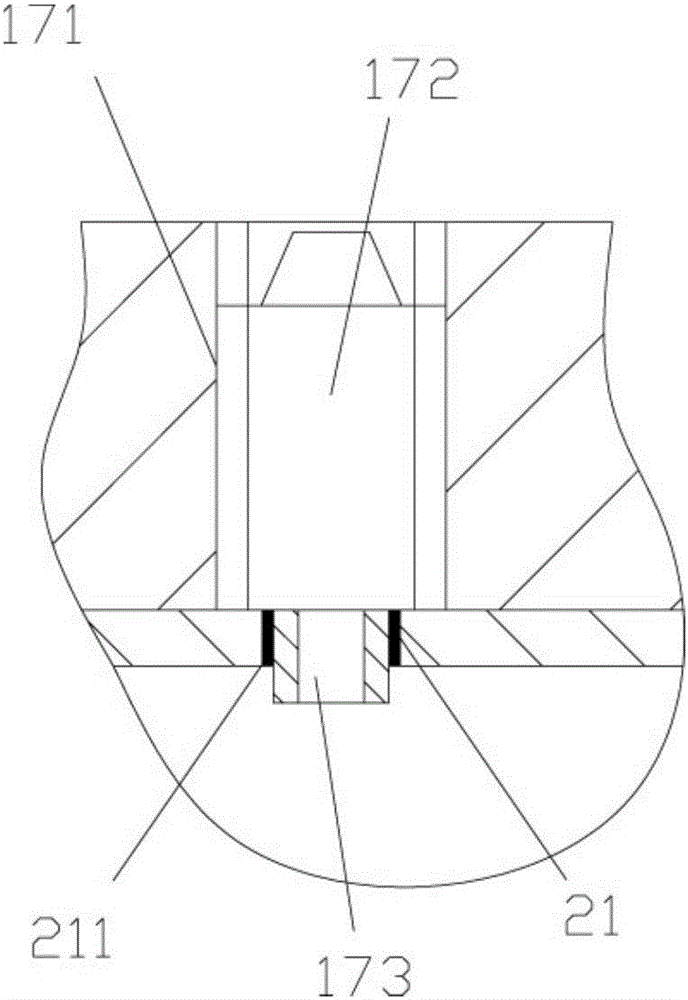

[0029] Vertical support plates 10 are fixed on both sides of the main bottom plate 100, the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com