Electromagnetic lever flat layer control and safety braking device for lifting device

A technology of lifting equipment and safety braking, which is applied in the direction of elevators, hoisting devices, transportation and packaging, etc., and can solve problems such as leveling accuracy changes, friction material wear, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

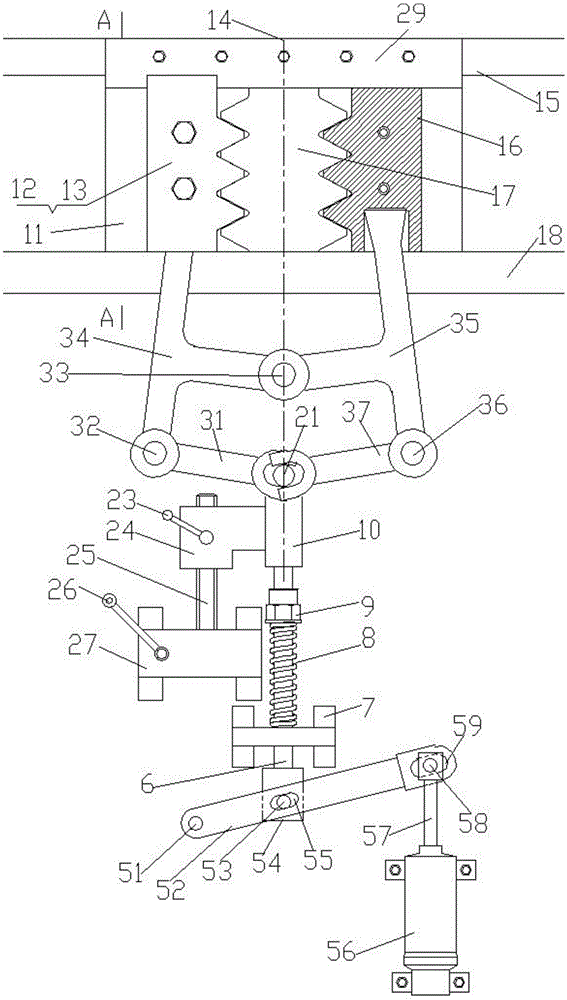

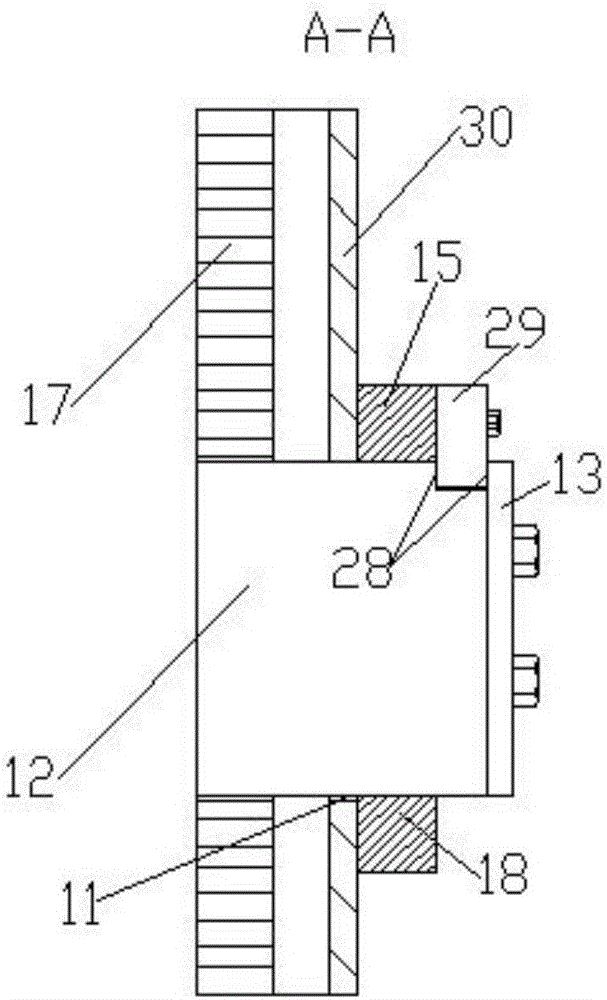

[0023] Example 1, Figure 8 It is a schematic diagram of embodiment 1, the drawing shows the appearance of the side of the lifting equipment, the electromagnetic lever leveling control safety brake device is installed on the rack and pinion lifting equipment and is temporarily in the braking state, Figure 9 It is a schematic diagram of the situation in which the lifting equipment electromagnetic lever leveling control safety brake device of the lifting equipment is installed in the first embodiment, the lifting equipment is in a free position state, the lifting equipment is ready to run or is running, (the left and right described in the previous figure, It is viewed from the inside of the lifting device to the side of the lifting device, Figure 8 , Figure 9 It is viewed from the outside to the side of the lifting equipment, so the left and right directions are just opposite), the electromagnetic lever leveling control safety brake device of the lifting equipment is closel...

Embodiment 2

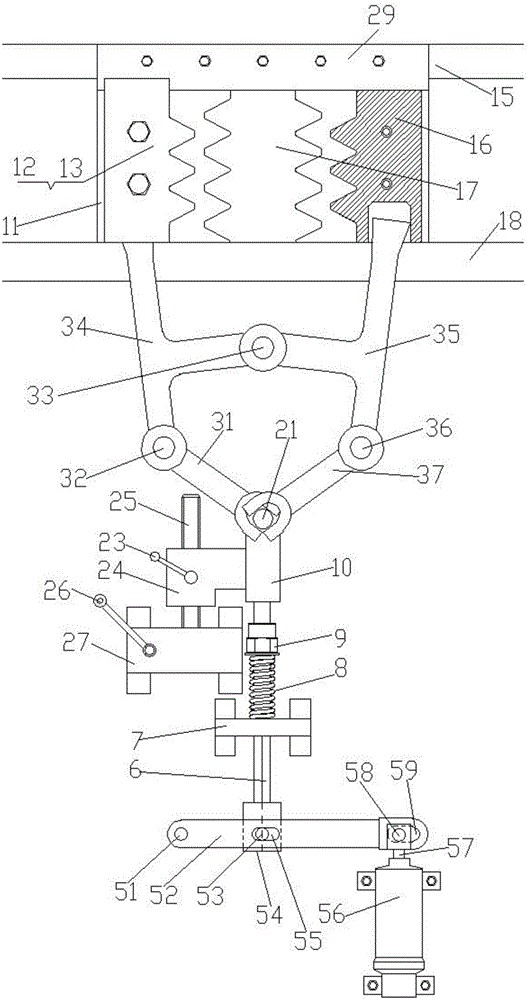

[0024] Embodiment 2 is a lifting device equipped with a lifting device electromagnetic lever leveling control safety brake device according to the present invention, Figure 10 It is a schematic diagram of embodiment 2, showing that the electromagnetic puller main body 56 is in a power-off state, and the situation when the electromagnetic lever leveling control safety braking device implements braking, Figure 11 It is a schematic diagram of when the electromagnetic puller main body 56 is in the energized state and the electromagnetic lever leveling control safety brake device is in a free position state in embodiment 2. The rack and pinion lifting equipment used in the electromagnetic lever leveling control safety brake device is specific The structure is an independent electromagnetic lever leveling control safety brake device assembly with independent components installed separately and then installed on the lifting equipment. Its structure and working principle are the same...

Embodiment 3

[0025] Embodiment 3, an elevator equipped with an electromagnetic lever leveling control safety brake device assembly directly installed on the lifting equipment, its appearance is the same as Figure 8 , Figure 9 , the working principle is the same as described in paragraph [0023].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com