A kind of ferric oxide micro-nano material, preparation method and application thereof

A ferric tetroxide, micro-nano technology, applied in the directions of iron oxide/iron hydroxide, nanotechnology, ferrous oxide, etc., can solve the problems of easy agglomeration and oxidation, complicated preparation process, and many raw materials added, etc. Achieve mild reaction conditions, good magnetic properties, and less use of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A preparation method of iron ferric oxide micro-nano material, the steps comprising:

[0037] A. Preparation of mixed solvent:

[0038] Mix 37 volumes of water with 3 volumes of glycerin, and magnetically stir for 30 minutes to prepare a uniform mixed solvent.

[0039] B, preparation of ferroferric oxide micro-nano material:

[0040] Dissolve a certain amount of potassium ferricyanide in the above-mentioned 40 volumes of mixed solvent, and magnetically stir to form an orange-yellow solution with a concentration of 0.02mol / L. Transfer the obtained solution to a polytetrafluoroethylene reactor, seal it, and React in an oven at 180°C for 5 hours;

[0041] C. Washing and drying:

[0042] After the above is finished, cool naturally to room temperature, centrifuge the product, wash the product 3-5 times with deionized water and ethanol, and dry it in vacuum at 60°C to constant weight to obtain ferric oxide micro-nano material.

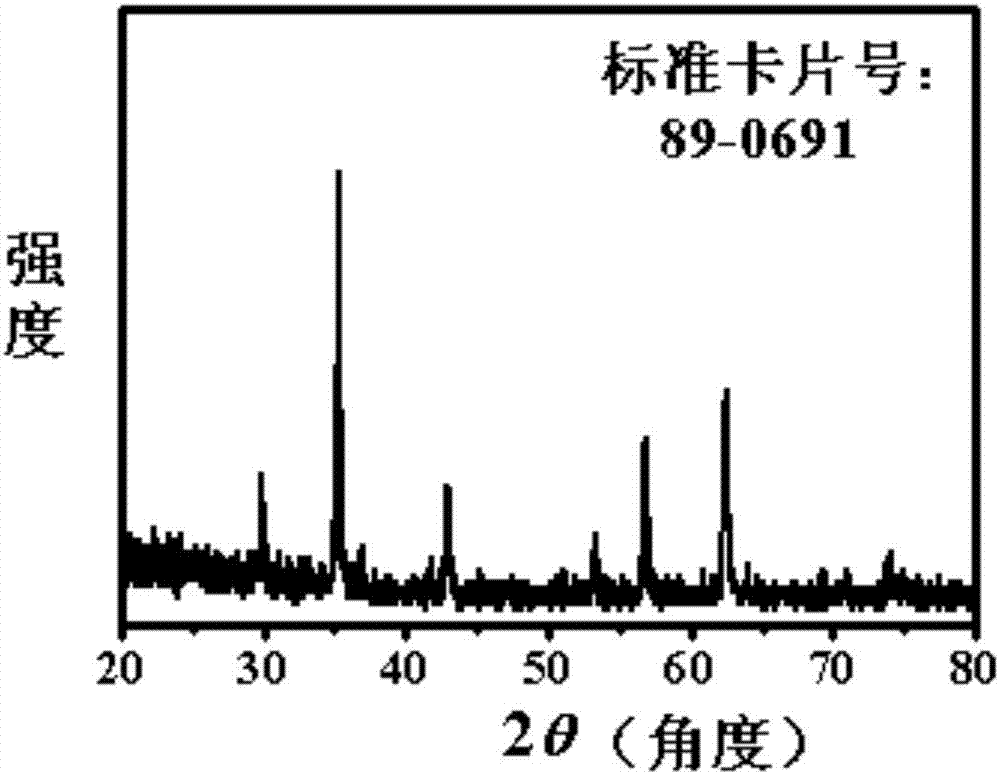

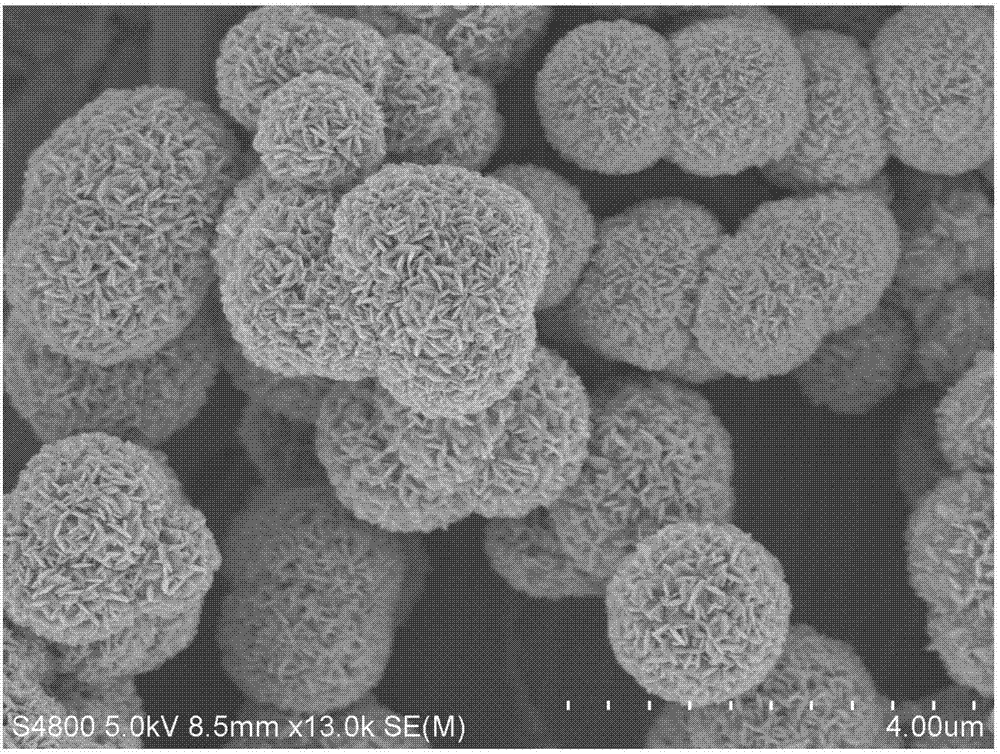

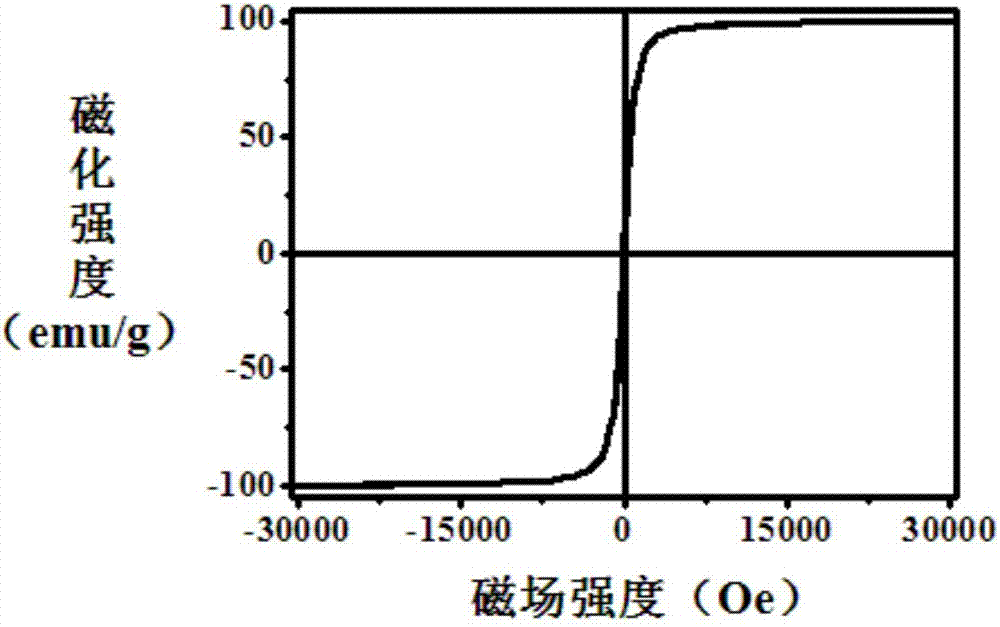

[0043]The prepared ferroferric oxide micro-...

Embodiment 2

[0047] A preparation method of iron ferric oxide micro-nano material, the steps comprising:

[0048] A. Preparation of mixed solvent:

[0049] Mix 38 volumes of water with 2 volumes of glycerin, and magnetically stir for 30 minutes to prepare a uniform mixed solvent.

[0050] B, preparation of ferroferric oxide micro-nano material:

[0051] Dissolve a certain amount of potassium ferricyanide in the above-mentioned 40 volume mixed solvent, fully magnetically stir to form an orange-yellow solution with a concentration of 0.025mol / L, transfer the above-obtained solution to a polytetrafluoroethylene reactor, seal it, React in an oven at 170°C for 20 hours.

[0052] C. Washing and drying:

[0053] After the above, naturally cool to room temperature, centrifuge the product, wash the product several times with deionized water and ethanol, and vacuum-dry it at 65°C to constant weight to obtain ferric oxide micro-nano material.

[0054] The prepared ferroferric oxide micro-nano mat...

Embodiment 3

[0056] A preparation method of iron ferric oxide micro-nano material, the steps comprising:

[0057] A. Preparation of mixed solvent:

[0058] Mix 35 volumes of water with 5 volumes of glycerin, and magnetically stir for 30 minutes to prepare a uniform mixed solvent.

[0059] B, preparation of ferroferric oxide micro-nano material:

[0060] Dissolve a certain amount of potassium ferricyanide in the above-mentioned 40 volume mixed solvent, fully magnetically stir to form an orange-yellow solution with a concentration of 0.04mol / L, transfer the above-obtained solution to a polytetrafluoroethylene reactor, seal it, React in an oven at 190°C for 4 hours.

[0061] C. Washing and drying:

[0062] After the above, naturally cool to room temperature, centrifuge the product, wash the product several times with deionized water and ethanol, and dry it in vacuum at 55°C to constant weight to obtain ferric oxide micro-nano material.

[0063] The prepared ferroferric oxide micro-nano ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com