Solid type diatom ooze wall material and preparation method thereof

A diatom mud and wall material technology, applied in the field of interior decoration materials, can solve the problems of easy blocking of diatomite pores, poor coating durability, and strong solvent odor, and achieve good grip, long service life, and enlarged pores. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

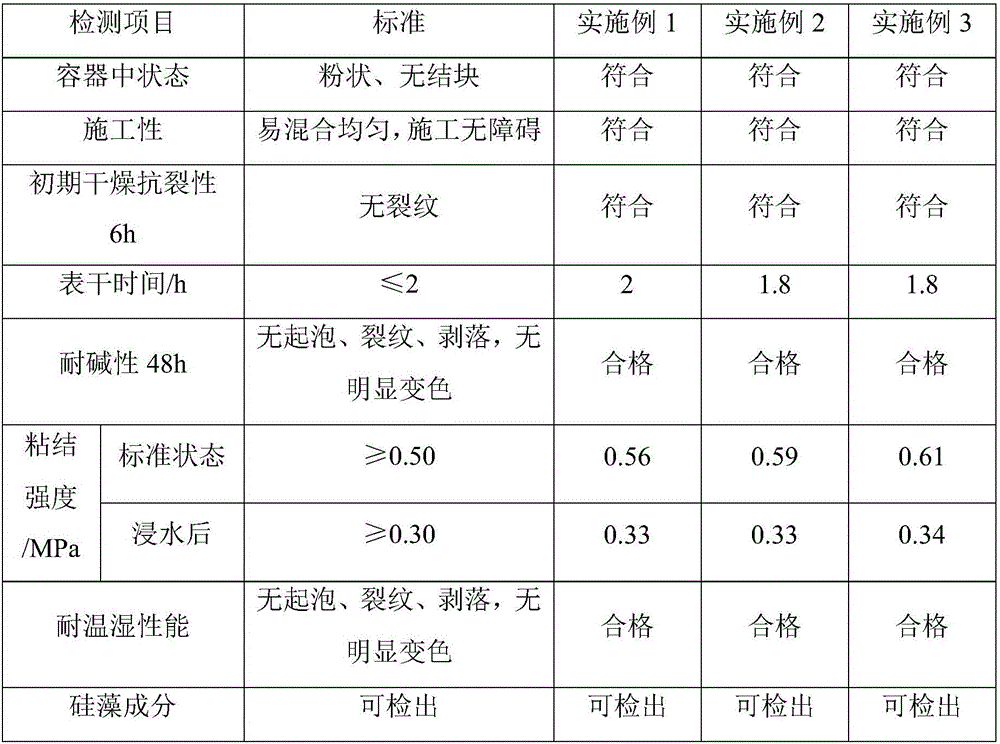

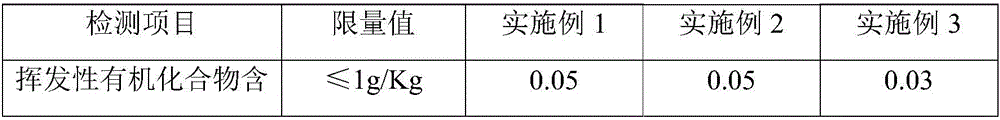

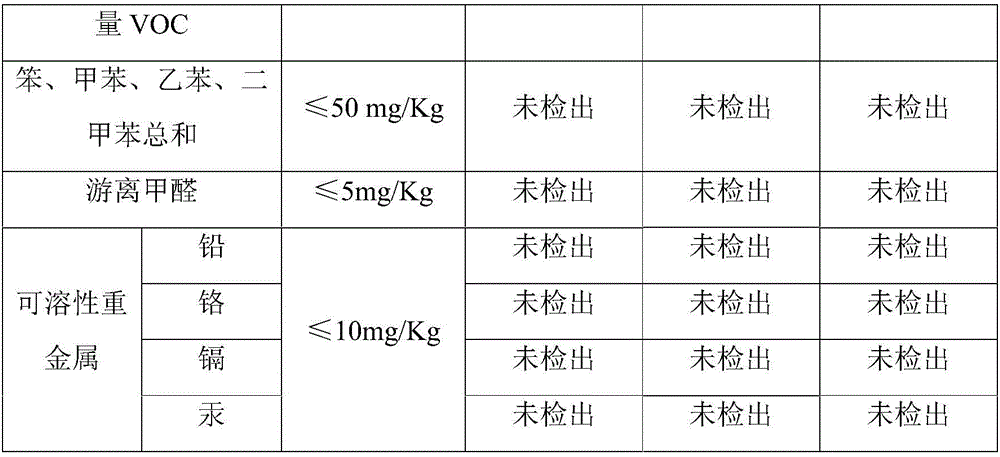

Examples

Embodiment 1

[0026] A strong diatom mud wall material. The raw materials for making the strong diatom mud wall material include the following components in parts by weight: 40 parts of diatomite, 6 parts of aramid pulp, aluminum silicate fiber 3 parts, 5 parts of white cement, 1 part of mineral pigment, 5 parts of water-based polyurethane, 1 part of hydroxypropyl cellulose, 1 part of sodium alginate, 5 parts of expanded vermiculite, 4 parts of alkyl glyceryl ether sulfonate, gum arabic Powder 1 part, soybean protein glue 1 part, carboxymethyl cellulose sodium 1 part.

[0027] The preparation method of described strong diatom ooze wall material comprises the following steps:

[0028] (1) After the diatomite is coarsely crushed, it is added to the nitric acid solution to form a mixed material solution with a diatomite weight percentage of 18%. The pH value of the nitric acid solution is 0.1, and it is ultrasonically After stirring for 30-60 minutes, wash and dry until the moisture accounts ...

Embodiment 2

[0033]A strong diatom mud wall material. The raw materials for making the strong diatom mud wall material include the following components in parts by weight: 60 parts of diatomite, 10 parts of aramid pulp, aluminum silicate fiber 6 parts, 7 parts of white cement, 3 parts of mineral pigment, 10 parts of water-based polyurethane, 3 parts of hydroxypropyl cellulose, 3 parts of sodium alginate, 7 parts of expanded vermiculite, 6 parts of alkyl glyceryl ether sulfonate, gum arabic 3 parts of powder, 3 parts of soybean protein glue, 2 parts of sodium carboxymethyl cellulose.

[0034] The preparation method of described strong diatom ooze wall material comprises the following steps:

[0035] (1) After the diatomite is coarsely crushed, it is added to the nitric acid solution to form a mixed material solution with a diatomite weight percentage of 30%. The pH value of the nitric acid solution is 0.4, and it is ultrasonicated at 60-80°C After stirring for 30-60 minutes, wash and dry u...

Embodiment 3

[0040] A strong diatom mud wall material. The raw materials for making the strong diatom mud wall material include the following components in parts by weight: 50 parts of diatomite, 8 parts of aramid pulp, aluminum silicate fiber 5 parts, 6 parts of white cement, 2 parts of mineral pigment, 8 parts of water-based polyurethane, 2 parts of hydroxypropyl cellulose, 2 parts of sodium alginate, 6 parts of expanded vermiculite, 5 parts of alkyl glyceryl ether sulfonate, gum arabic 2 parts of powder, 2 parts of soybean protein glue, 1.5 parts of sodium carboxymethyl cellulose.

[0041] The preparation method of described strong diatom ooze wall material comprises the following steps:

[0042] (1) After the diatomite is coarsely crushed, it is added to the nitric acid solution to form a mixed material solution with a diatomite weight percentage of 25%. The pH value of the nitric acid solution is 0.3, and it is ultrasonicated at 60-80°C After stirring for 30-60 minutes, wash and dry ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap