Silk-screen environmental-friendly watercolor ink and preparation method thereof

A watercolor and ink technology, applied in inks, household appliances, applications, etc., can solve the problems of poor printing adaptability, unsuitable for printing industrial use, no adhesion of watercolor pigments, etc., to achieve the effect of convenient use and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An environmentally friendly watercolor ink for screen printing, comprising the following ingredients in proportion by weight: 40 parts of filler, 5 parts of glycerin, 20 parts of water-based acrylic resin, 10 parts of water-based color paste, 20 parts of deionized water, 2 parts of leveling agent, defoaming agent 1 part of agent, 2 parts of wetting agent.

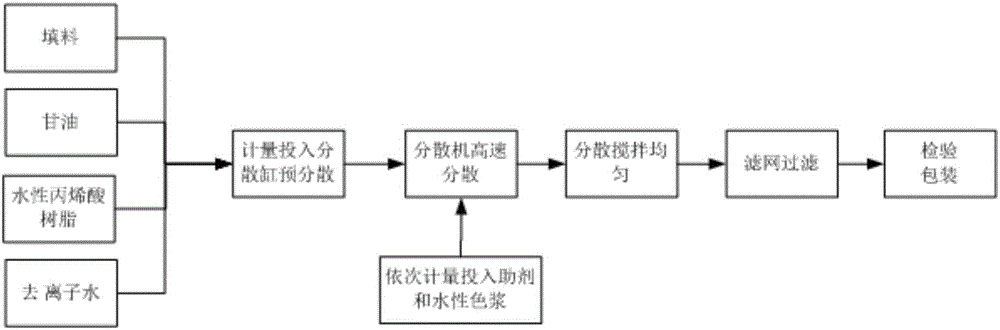

[0017] A preparation method of screen printing environmental protection watercolor ink, comprising the following steps:

[0018] A. First add deionized water, glycerin, water-based acrylic resin and filler to the dispersion tank and stir for 30 minutes at 250 rpm;

[0019] B. Adjust the rotation speed to 750rpm, then add leveling agent, wetting agent, defoamer in turn and continue to stir for 30 minutes, and finally add water-based color paste, stir for 20 minutes to generate watercolor ink;

[0020] C. Filter the uniformly dispersed water-based ink to obtain the finished watercolor ink.

Embodiment 2

[0022] An environmentally friendly watercolor ink for screen printing, comprising the following ingredients in proportion by weight: 35 parts of filler, 10 parts of glycerin, 20 parts of water-based acrylic resin, 10 parts of water-based color paste, 20 parts of deionized water, 2 parts of leveling agent, defoaming agent 1 part of agent, 3 parts of wetting agent.

[0023] A preparation method of screen printing environmental protection watercolor ink, comprising the following steps:

[0024] A. First add deionized water, glycerin, water-based acrylic resin and filler to the dispersion tank and stir for 25 minutes at 300 rpm;

[0025] B. Adjust the speed to 800rpm, then add leveling agent, wetting agent, defoamer in turn and continue to stir for 20 minutes, and finally add water-based color paste, stir for 30 minutes to generate watercolor ink;

[0026] C. Filter the uniformly dispersed water-based ink to obtain the finished watercolor ink.

Embodiment 3

[0028] An environmentally friendly watercolor ink for silk screen printing, comprising the following ingredients in proportion by weight: 42 parts of filler, 8 parts of glycerin, 23 parts of water-based acrylic resin, 7 parts of water-based color paste, 24 parts of deionized water, 1.5 parts of leveling agent, defoaming agent 1.5 parts of agent, 2.5 parts of wetting agent.

[0029] A preparation method of screen printing environmental protection watercolor ink, comprising the following steps:

[0030] A. First add deionized water, glycerin, water-based acrylic resin and filler to the dispersion tank and stir for 35 minutes at 200 rpm;

[0031] B. Adjust the rotation speed to 600rpm, then add leveling agent, wetting agent, defoamer in turn and continue to stir for 35 minutes, and finally add water-based color paste, stir for 15 minutes to generate watercolor ink;

[0032] C. Filter the uniformly dispersed water-based ink to obtain the finished watercolor ink.

[0033] The vis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com