Heat conduction adhesive and preparation method of adhesive tape employing same

A technology of adhesives and thermally conductive adhesives, applied in the direction of adhesive additives, adhesives, non-polymer adhesive additives, etc., can solve the problems of low thermal conductivity, high price, and reduced adhesive properties of adhesives, and achieve thermal conductivity High, low production cost, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

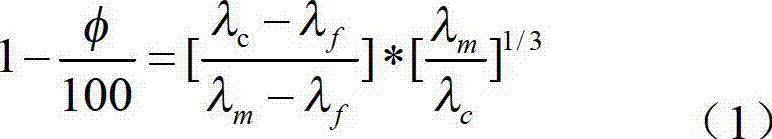

Method used

Image

Examples

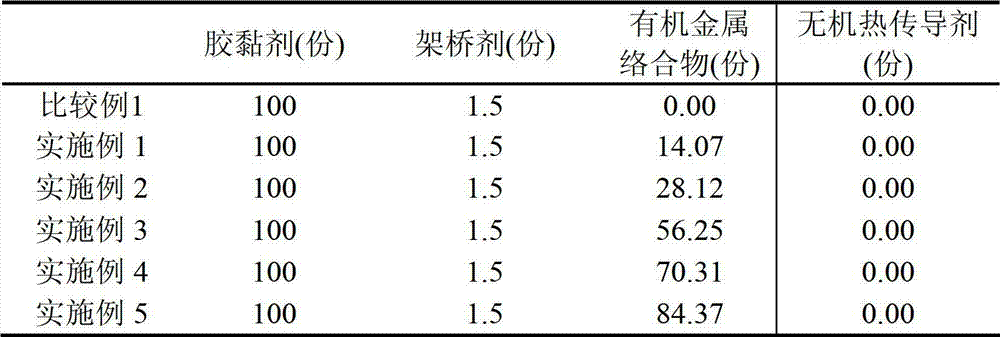

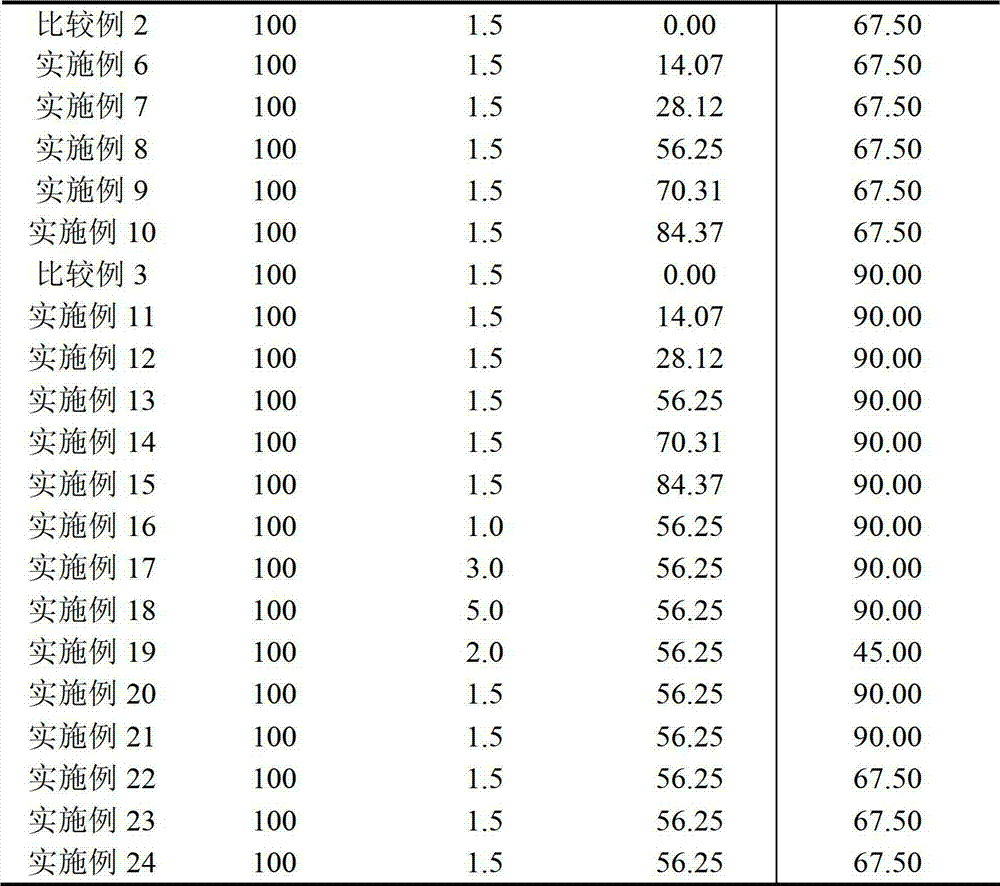

Embodiment 1

[0038] 1. Configuration of organometallic copper complex solution: Take 8 parts of copper phthalocyanine complex powder and add it to 92 parts of butanone MEK solvent, stir well until it is completely dissolved, and the solid content is 8%.

[0039] 2. The configuration of the adhesive mixture: Take 100 parts of acrylate adhesive (solid content 45%), add 14.07 parts of copper phthalocyanine complex solution, stir well and add 1.5 parts of isocyanate crosslinking agent II Methylene diisocyanate (XDI) (solid content 45%), and continue to stir until uniform.

[0040] 3. Adhesive coating: apply the above adhesive mixture on the release paper with high release force, the thickness of the coating is 40 μm, dry in an oven at 80°C for 2 minutes, and use soft aluminum foil or upper release force Laminated with release paper, matured in an oven at 40°C for 3 days, and then cut into adhesive tapes.

Embodiment 2

[0042] 1. Configuration of organometallic copper complex solution: Take 8 parts of copper phthalocyanine complex powder and add it to 92 parts of butanone MEK solvent, stir well until it is completely dissolved, and the solid content is 8%.

[0043]2. The configuration of the adhesive mixture: Take 100 parts of acrylate adhesive (solid content 45%), add 28.12 parts of copper phthalocyanine complex solution, stir well and add 1.5 parts of isocyanate crosslinking agent II Methylene diisocyanate (XDI) (solid content 45%), and continue to stir until uniform.

[0044] 3. Adhesive coating: apply the above adhesive mixture on the release paper with high release force, the thickness of the coating is 40 μm, dry in an oven at 80°C for 2 minutes, and use soft aluminum foil or upper release force Laminated with release paper, matured in an oven at 40°C for 3 days, and then cut into adhesive tapes.

Embodiment 3

[0046] 1. Configuration of organometallic copper complex solution: Take 8 parts of copper phthalocyanine complex powder and add it to 92 parts of butanone MEK solvent, stir well until it is completely dissolved, and the solid content is 8%.

[0047] 2. The configuration of the adhesive mixture: take 100 parts of acrylate adhesive (solid content 45%), add 56.25 parts of copper phthalocyanine complex solution, stir well and add 1.5 parts of isocyanate crosslinking agent II Methylene diisocyanate (XDI) (solid content 45%), and continue to stir until uniform.

[0048] 3. Adhesive coating: apply the above adhesive mixture on the release paper with high release force, the thickness of the coating is 40 μm, dry in an oven at 80°C for 2 minutes, and use soft aluminum foil or upper release force Laminated with release paper, matured in an oven at 40°C for 3 days, and then cut into adhesive tapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com