Snow cleaning compaction forming output machine

An output machine and snow accumulation technology, which is applied in snow surface cleaning, cleaning methods, construction, etc., can solve the problems of laborious and laborious, occupying the road surface, and a thin layer of snow, so as to increase transportation efficiency and solve the problem of snow accumulation on roads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

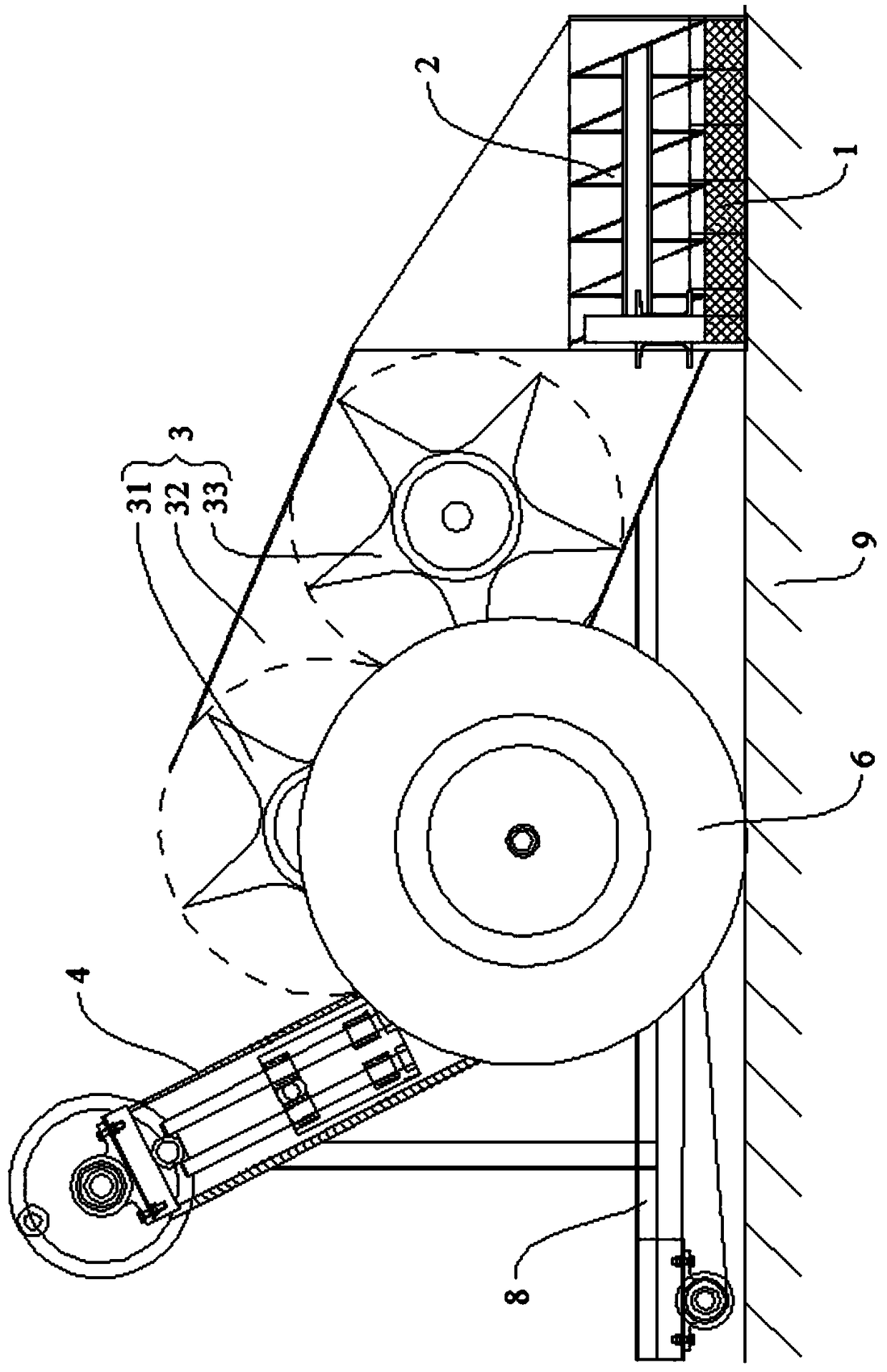

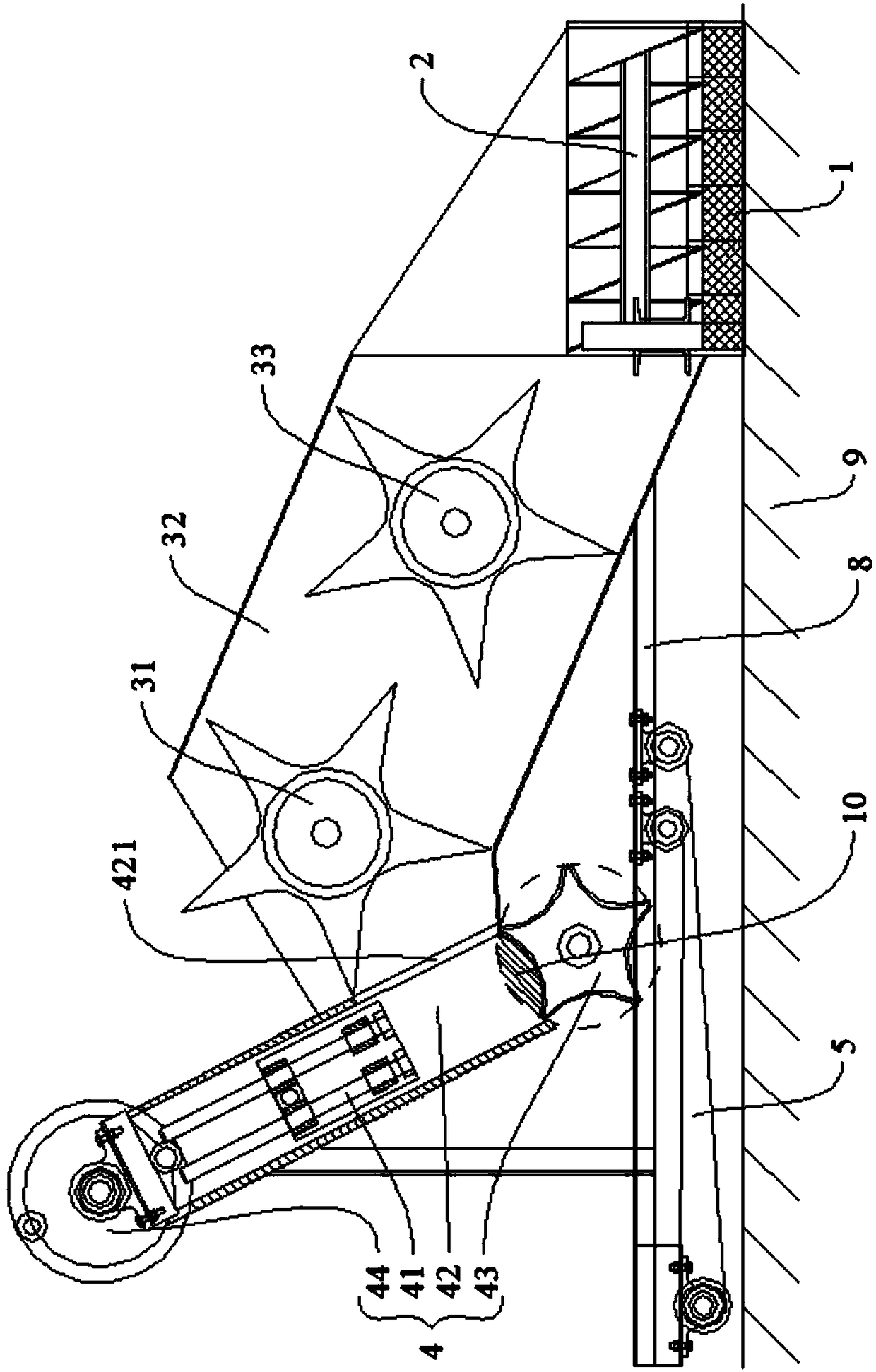

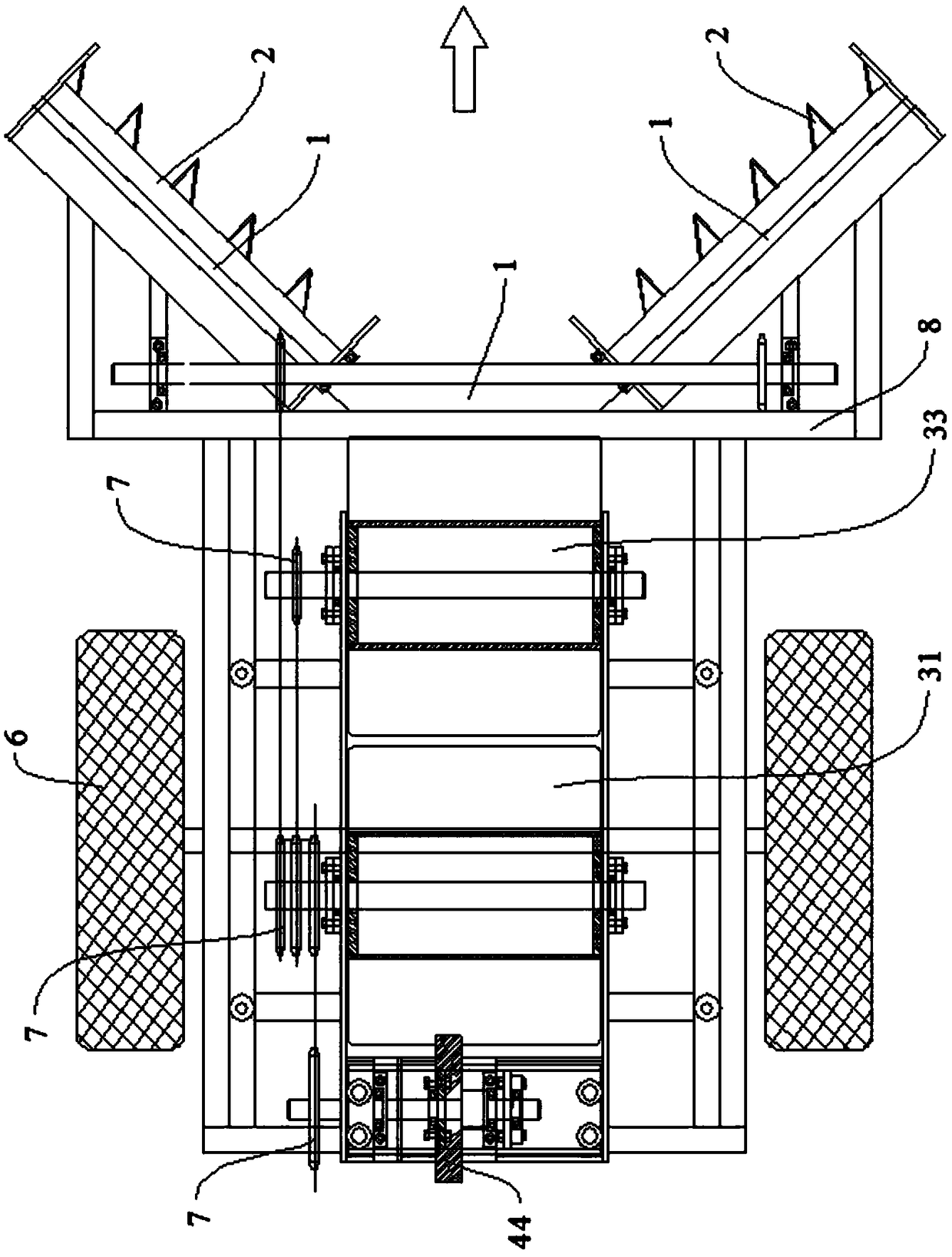

[0020] attached figure 1 , 2 The dotted line in the middle is the circumference where the tooth tips of the toothed rollers are located, but it should not be understood as a limitation on the positional relationship between the toothed rollers.

[0021] attached image 3 The rubber push blades marked in image 3 The angle of view is invisible, and it is drawn here to express its structure and position.

[0022] as attached Figure 1~3 As shown, a snow clearing and compacting forming output machine includes: rubber push shovel 1, screw snow delivery mechanism 2, lifting mechanism 3, compression mechanism 4, conveying mechanism 5, storage bin, walking wheel 6, transmission mechanism 7, Vehicle frame assembly 8; wherein, the traveling wheels 6 are arranged on both sides of the vehicle frame assembly 8, and a screw snow delivery mechanism 2 is installed on the front side of the vehicle frame assembly 8. The outside of vehicle frame assembly 8 is inclined (that is: if the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com