A supercharged engine intake

A supercharged engine and air intake technology, applied in engine components, machines/engines, intake mufflers, etc., can solve the problem of high air temperature, and achieve the effects of solving airflow noise, reliable matching and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

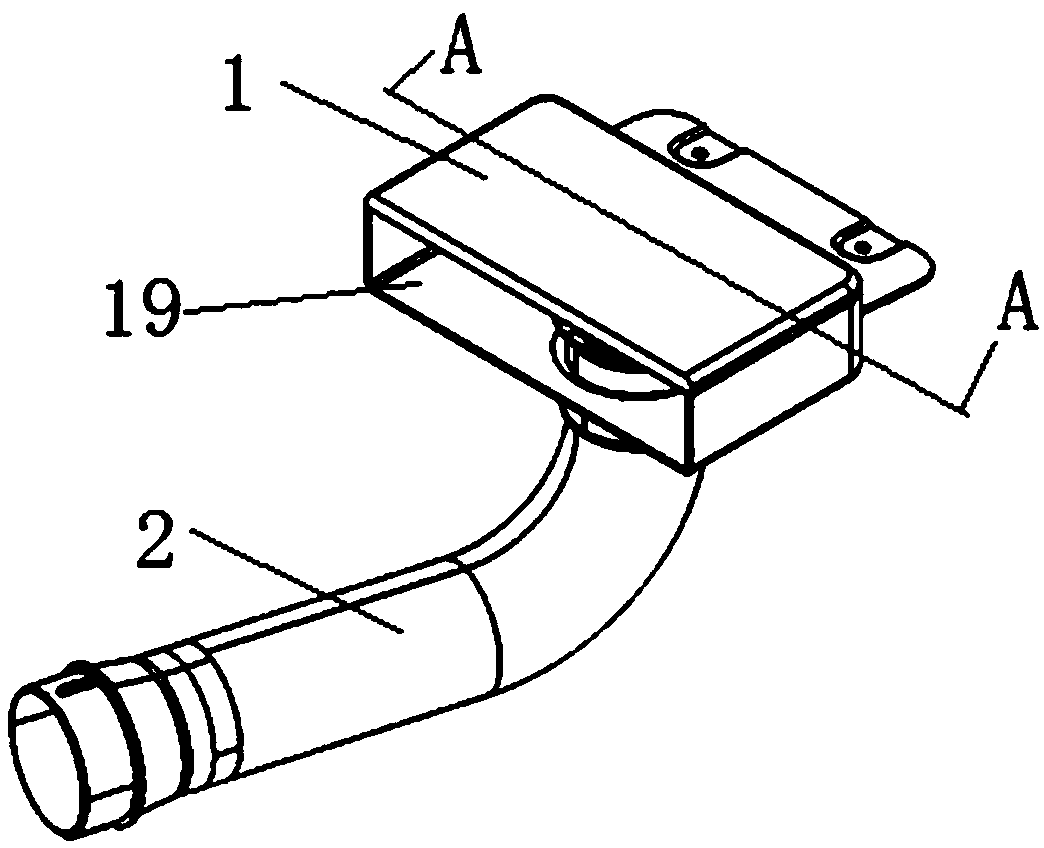

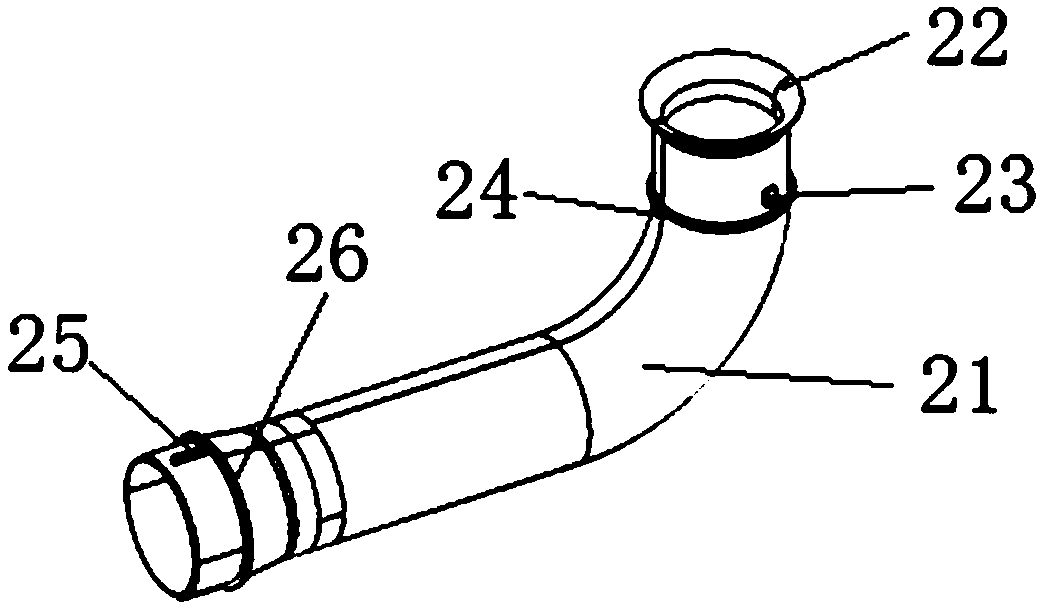

[0028] The application provides a supercharged engine intake, such as Figure 1 to Figure 4 As shown, a first air inlet 1 and a second air inlet 2 are included, and the first air inlet 1 and the second air inlet 2 are snap-connected.

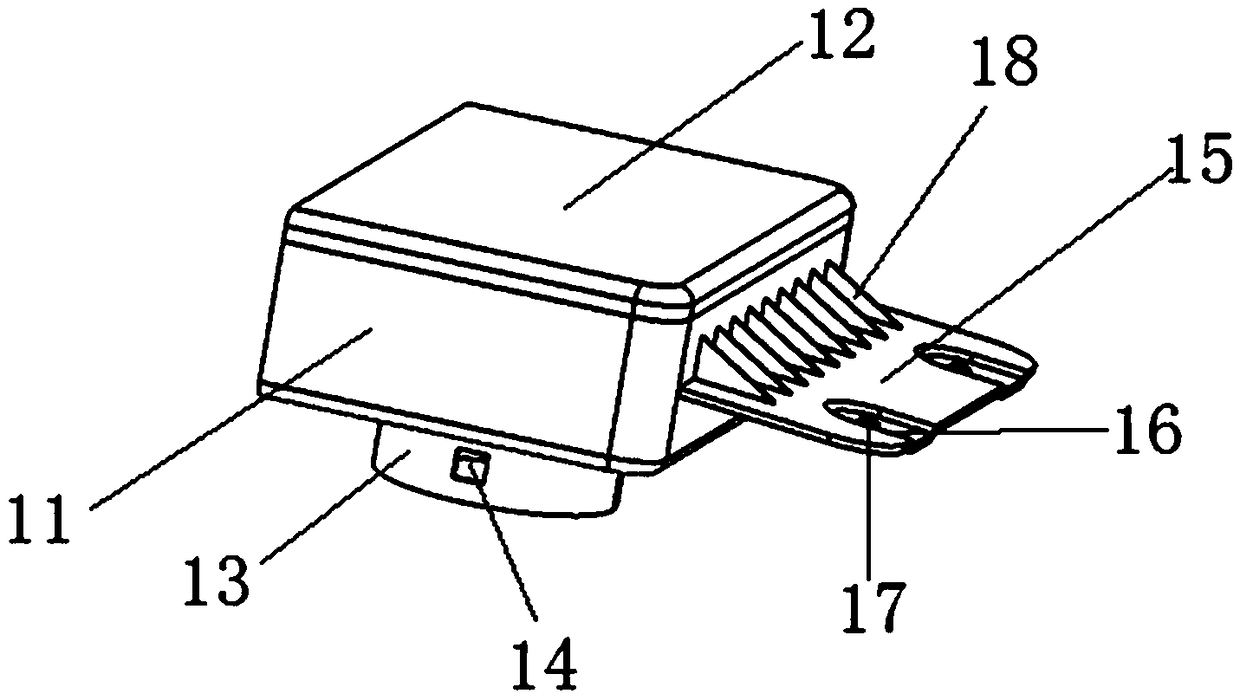

[0029] The first air inlet is a box-shaped structure with a first air inlet on one side, including a first air inlet body 11 and a box cover 12; the shape of the first air inlet is a box shape lacking a side structure, wherein the missing side forms the first air inlet 19. In this embodiment, both the first air inlet body and the box cover are plastic parts, and are joined by a plastic welding process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com