Combined bearing plate, pressure uniform anchor cable and installation method thereof

A load-bearing plate and combined technology, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., to achieve the effects of reducing installation difficulties, facilitating installation, and improving cable-making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

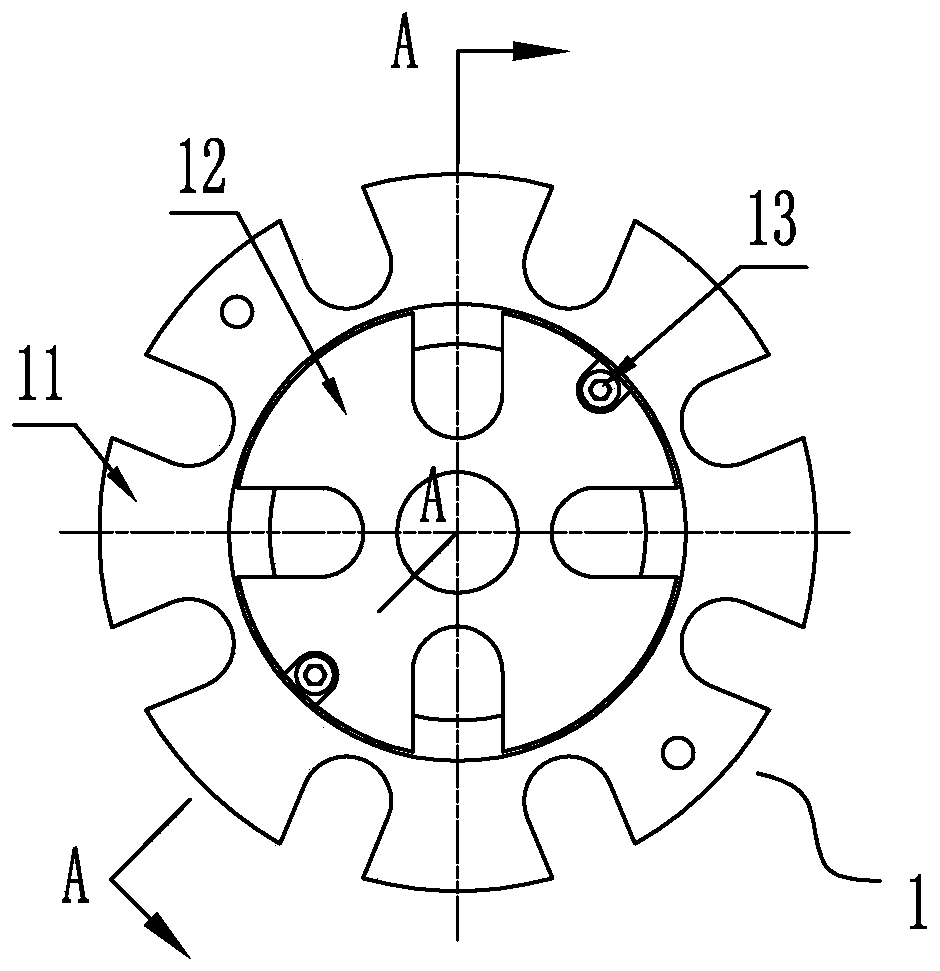

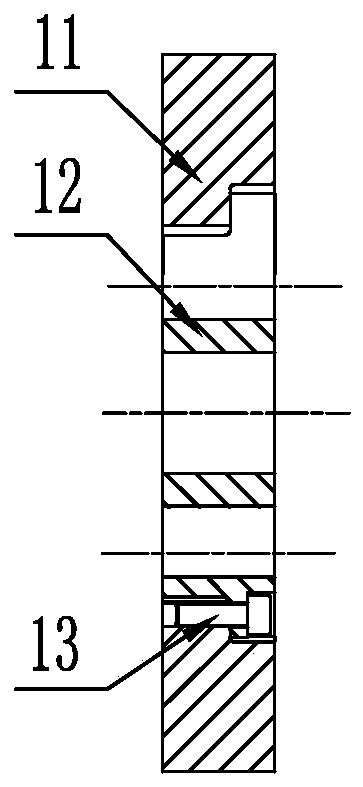

[0069] A combined bearing plate for a pressure-distributed anchor cable, such as Figure 1-Figure 2 As shown, the combined bearing plate includes an outer bearing plate 11 and an inner bearing plate 12;

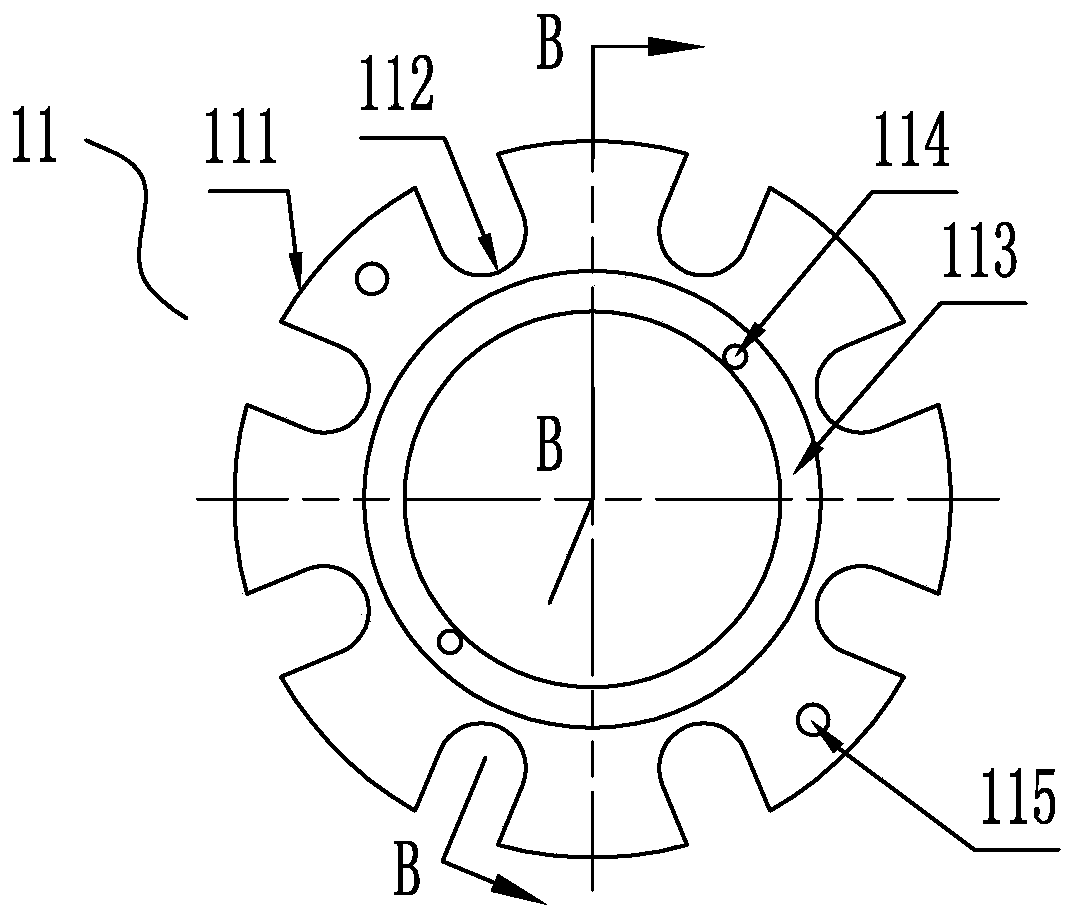

[0070] Such as Figure 3-Figure 4 As shown, the outer bearing plate 11 includes an annular outer bearing plate body 111, the outer edge of the outer bearing plate body 111 is provided with 8 arc-shaped grooves I112 for installing prestressed tendons, and the upper surface of the outer bearing plate body 111 is A bolt hole 115 is opened, and the center of the outer bearing plate body 111 is an annular step hole I113, and a screw hole 114 is opened on the annular step hole I113;

[0071] Such as Figure 5-Figure 7 As shown, the inner bearing plate 12 includes a circular inner bearing plate body 121; the outer edge of the inner bearing plate body 121 is an annular step I123, on which are provided four arc-shaped grooves II122 for installing prestressed tendons, There is a scr...

Embodiment 2

[0076] A pressure-distributed anchor cable, such as Figure 9-Figure 10 As shown, the pressure-distributed anchor cable includes an outer anchor head part and an inner anchor section, and the inner anchor section includes an anchor cable body and a multi-stage cable body bearing structure. Position plate and bearing plate, described bearing plate is to implement a described combined bearing plate 1, and this combined bearing plate includes outer bearing plate 11 and inner bearing plate 12 (see Figure 1-Figure 2 );

[0077] Such as Figure 3-Figure 4 As shown, the outer bearing plate 11 includes an annular outer bearing plate body 111, the outer edge of the outer bearing plate body 111 is provided with m arc-shaped grooves I112 for installing prestressed tendons, and the upper surface of the outer bearing plate body 111 is A bolt hole 115 is opened, and the center of the outer bearing plate body 111 is an annular step hole I113, and a screw hole 114 is opened on the annular ...

Embodiment 3

[0087] A method for installing a pressure uniform anchor cable.

[0088] The pressure evenly distributed anchor cable is the pressure evenly distributed anchor cable described in Embodiment 2, and the specific steps of the installation method are:

[0089] A. Install the carrier on the prestressed tendons;

[0090] B. Install prestressed tendons on the inner bearing plate:

[0091] Install the prestressed tendons 2 of the carrier body 3 into the arc-shaped groove II 122 for installing the prestressed tendons on the outer edge of the inner carrier plate body 121 of the inner carrier plate 12 respectively;

[0092] C. Assemble the combined bearing plate:

[0093] Nest the inner bearing plate 12 in the outer bearing plate 11, position it with the screw hole 114, make the annular step I123 of the inner bearing plate 12 cooperate with the annular step hole I113 of the outer bearing plate 11, and connect them as a whole through the screw 13 to form a Combined bearing plate 1;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com