Concrete grouting construction device and method at the bottom of a steel pipe pile

A construction method and construction device technology, applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of losing the original properties of concrete, waste, and increasing the error of concrete pouring level in the pipe, so as to save the cleaning process, The effect of saving engineering cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

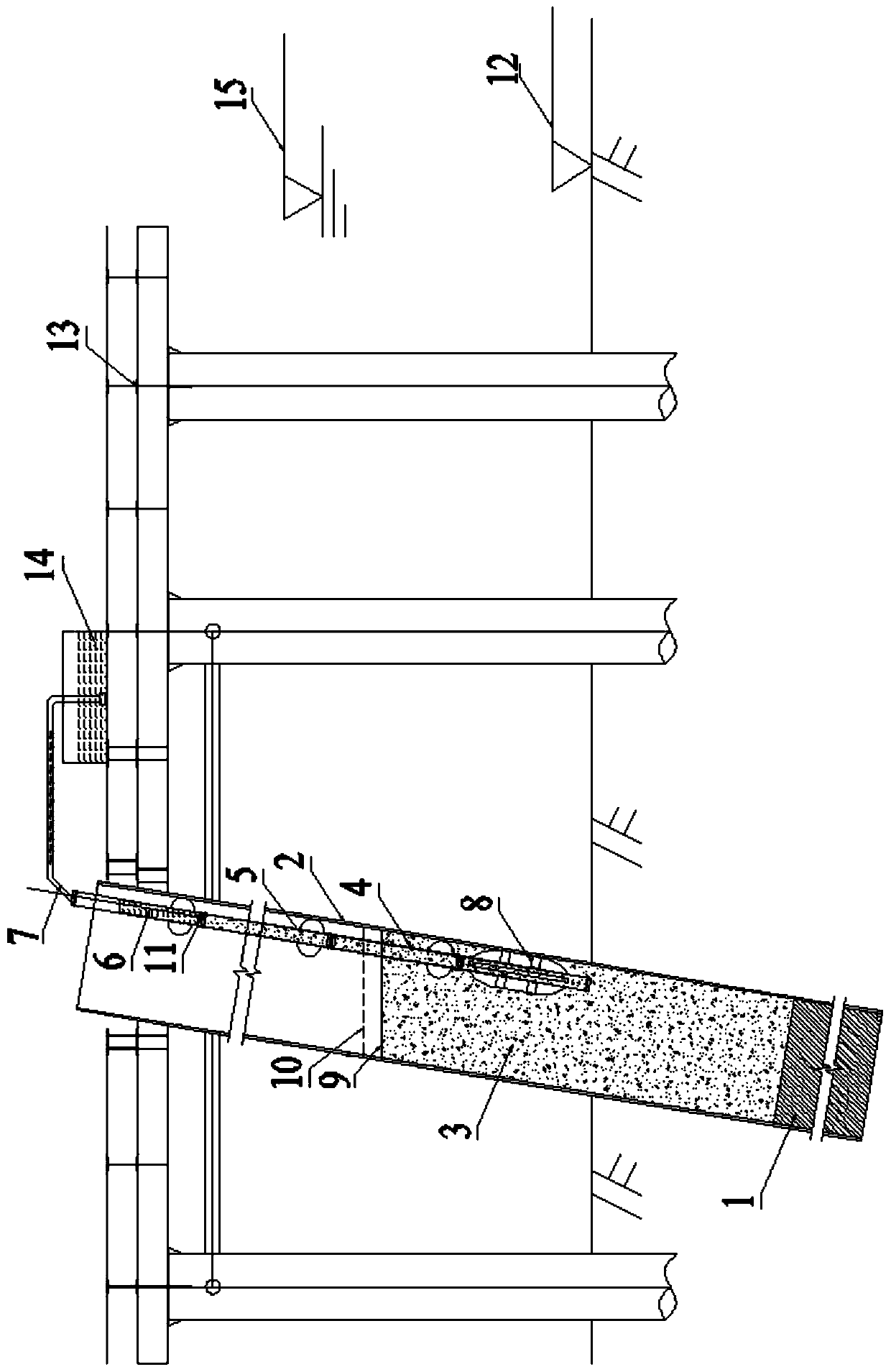

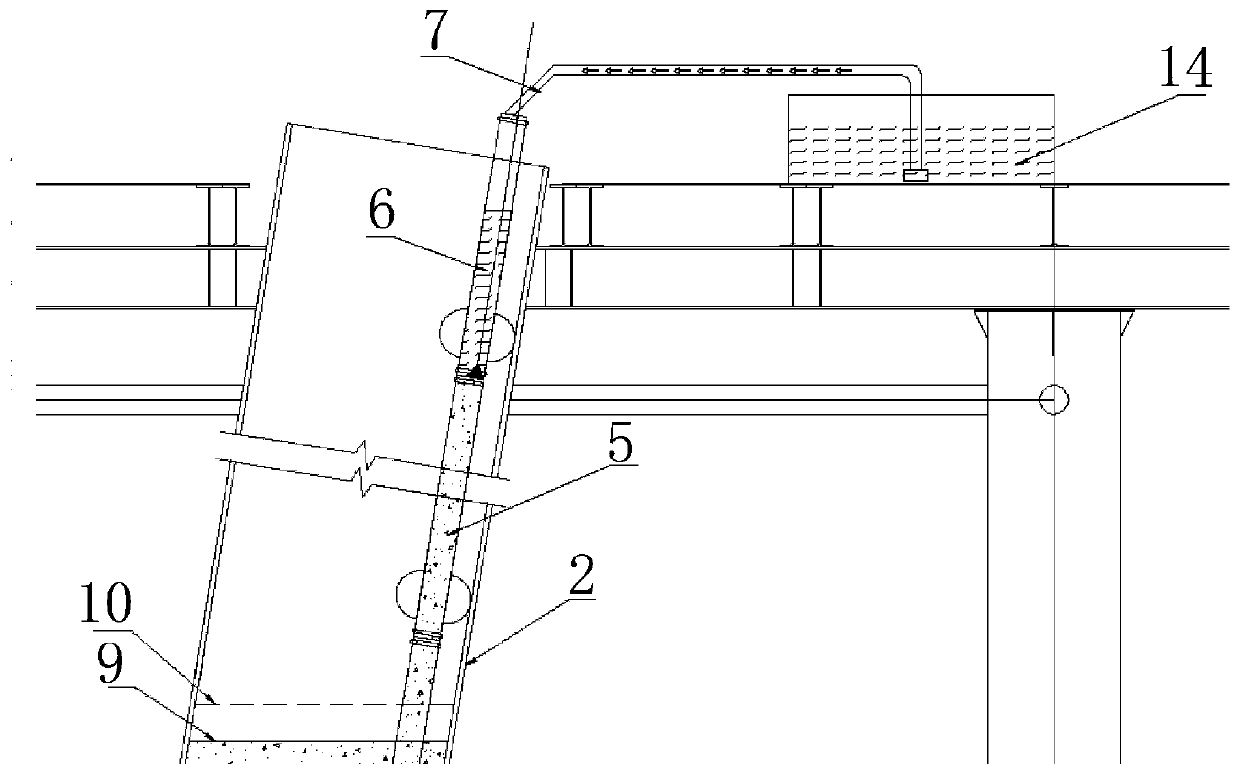

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0034] In the erection process of the existing steel pipe piles, generally after the steel pipe piles are inserted and driven to the design elevation, soil is taken from the piles and a certain length of soil plugs are reserved; then the concrete pouring construction at the bottom of the piles will be carried out.

[0035] The existing steel pipe pile pile bottom concrete pouring construction method comprises the following steps:

[0036] a1: Construction preparation: including but not limited to: conduct watertightness test of conduit, concrete mix test, prepare concrete production and transportation equipment;

[0037] a2: Install the conduit and install the perfusion funnel;

[0038] a3: Production and transportation of concrete;

[0039] a4: pouring underwater concrete. Accurately record the volume of poured concrete during concrete pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com